Titanium forging ensures strength, lightness & biocompatibility—ideal for aerospace & medical parts. Discover why it’s shaping the future of critical applications.

Titanium forging ensures strength, lightness & biocompatibility—ideal for aerospace & medical parts. Discover why it's shaping the future of critical applications.

Introduction: The Need for High-Performance Materials

In sectors where failure is not an option, such as aerospace and medical industries, materials used must possess superior strength, corrosion resistance, fatigue performance, and lightweight properties. Titanium, a metal once considered exotic and expensive, has now emerged as a material of choice due to its exceptional mechanical and chemical properties.

When forged, titanium transforms into high-integrity parts that outperform cast, machined, or fabricated alternatives. In this article, we explain why Titanium Forging is the future and how Adhvika Forge Tech Pvt. Ltd. is helping industries harness its full potential.

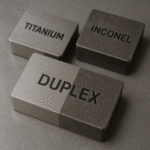

Why Titanium | Inconel | Duplex ?

Titanium is a high-performance metal with several standout features:

High Strength-to-Weight Ratio

Corrosion Resistance (even in saltwater and chemical environments)

Biocompatibility (perfect for implants and prosthetics)

Non-Magnetic and Non-Toxic Properties

Can Withstand Extreme Temperatures

These qualities make it an irreplaceable material in industries where safety and performance are critical.

✈️ Titanium in Aerospace Industry

Titanium’s role in aerospace is increasing year by year. Why?

Fuel Efficiency: Lightweight components mean lower fuel consumption.

Structural Integrity: High tensile strength withstands immense pressure and turbulence.

Thermal Stability: Ideal for jet engines and high-temperature zones.

Corrosion Resistance: Aircrafts operate in diverse and extreme environments.

✈️ Key Aerospace Forged Titanium Components:

Compressor blades

Landing gear parts

Structural frames

Fasteners and brackets

Turbine discs

Adhvika Forge Tech provides Electric Screw Presses, Hydraulic Presses, and custom forging lines that are specifically designed for titanium and aluminum alloy forging used in aerospace components.

🏥 Titanium in Medical Industry

Titanium is known as the “metal of the future” in medicine. Here’s why:

Biocompatibility: The human body accepts titanium naturally.

Non-Toxic & Non-Magnetic: Ideal for MRIs and X-rays.

Durability: High wear resistance ensures longevity of implants.

Corrosion Proof: Doesn’t react with bodily fluids.

🦴 Popular Titanium Medical Components:

Hip & Knee Implants (Orthopedic)

Dental Implants

Bone screws and plates

Surgical instruments

Spine components

Adhvika Forge Tech is actively involved in developing orthopedic forging lines, supplying press solutions that meet strict ISO & FDA standards.

🛠️ Forging vs. Other Manufacturing Methods

| Process | Cost-Effective | High Strength | Ideal for Titanium |

|---|---|---|---|

| Machining | ❌ | ✅ | ❌ (High wastage) |

| Casting | ✅ | ❌ | ❌ (Porosity risk) |

| Forging | ✅ | ✅ | ✅ (Best method) |

Forging is the only method that offers both material integrity and cost optimization — crucial for aerospace and medical-grade parts.

Adhvika Forge Tech – Your Titanium Forging Partner