Our Services – Adhvika Forge Tech

Adhvika Forge Tech is a leading supplier of advanced forging machines including electric screw, hydraulic, mechanical press, C-frame, and pneumatic hammer systems. We specialize in turnkey project management, forging consultancy, repair services, and product development, offering complete solutions tailored to meet diverse industrial needs.

We provide complete solutions for the forging industry, including:

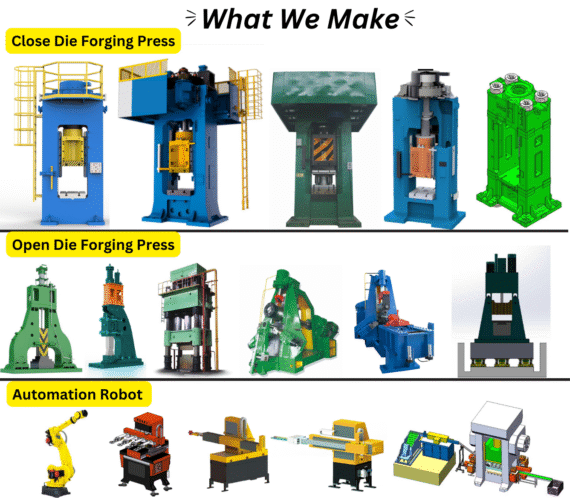

✅ Forging Machine Supply – Low-cost, high-quality machines for open die and close die forging.

✅ Automation & Industrial Services – Upgrading forging lines for better efficiency and production.

✅ Turnkey Project Solutions – Complete setup from machine installation to production.

✅ Forging Consultancy – Expert guidance on process improvement and cost reduction.

✅ Overhauling & Repair Services – Mechanical, electrical, and hydraulic press repairs.

✅ Product Development – Custom forging solutions for aerospace, automotive, medical, and more.

We deliver reliable and cost-effective solutions for your forging needs!

Why Choose Adhvika ForgeTech Pvt. Ltd.

Adhvika ForgeTech offers a wide range of forging machines to suit every industry need. Advantages of Choosing Adhvika ForgeTech with Over 100 Years of Combined Team Forging Industry Experience.

Aerospace Industry

Forging plays a crucial role in the aerospace industry, where strength, reliability..

Read More

Medical Industry

Forging titanium and titanium alloys for orthopedic joints and dental implants exemplifies..

Read More

Mechanical Engineering

We specialize in providing turnkey solutions for the forging of heavy machine parts..

Read More

Defence Industry

Forging is a key process in the defence industry, ensuring high-strength, durable, and precision..

Read More

Oil & Gas Industry

We provide forging solutions for critical components in the Oil & Gas Industry, ensuring strength..

Read More

Looking an adequate solution for your forging company

About us

Leading the Forging Industry Since 2018

Since 2018, Adhvika Forge Tech has been a trusted name in the forging industry, providing high-quality machines, turnkey solutions, and expert services globally.

- ✅ All Type Forging Machine & Services

- ✅ Global Presence

- ✅ Cost-Effective Solutions

- ✅ Complete Forging Line Setup

- ✅ Customer-First Approach

- ✅ Forging Solution One Window

Ask Question?

A forging turnkey solution means providing a complete setup for forging production, from machine installation to final product development. It includes planning, project management, forging plant layout equipment supply, process setup, and training to ensure smooth operations.

Project management in forging involves designing, implementing, and optimizing the entire production process, ensuring efficiency, cost-effectiveness, and high-quality output.

At Adhvika Forge Tech, we offer end-to-end forging solutions, helping industries set up fully functional and low-cost forging units with expert guidance and support.

✅ Yes, we offer a standard warranty covering manufacturing defects and major components. The warranty period depends on the machine type and specifications.

✅ We provide after-sales service, technical support, and spare parts availability to ensure smooth operation. Some key components come with a performance guarantee based on industry standards.

🔹 Q: Do you provide product design services for forging?

✅ Yes, at Adhvika Forge Tech, we offer complete product design solutions, including CAD modeling, die design, and process optimization, ensuring high-precision and cost-effective manufacturing.

🔹 Q: What is RFQ (Request for Quotation) in forging?

✅ RFQ is a formal request sent to manufacturers or suppliers to get pricing, production timelines, and technical details for a specific forged component. We assist in RFQ preparation, ensuring accurate cost estimation and feasibility analysis.

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.

Our Forging Machines & Capabilities

At Adhvika Forge Tech, we deliver a complete range of industrial forging equipment designed for precision, durability, and long service life. Our machines are built to handle the toughest manufacturing demands, supporting industries from aerospace and automotive to medical and heavy engineering.

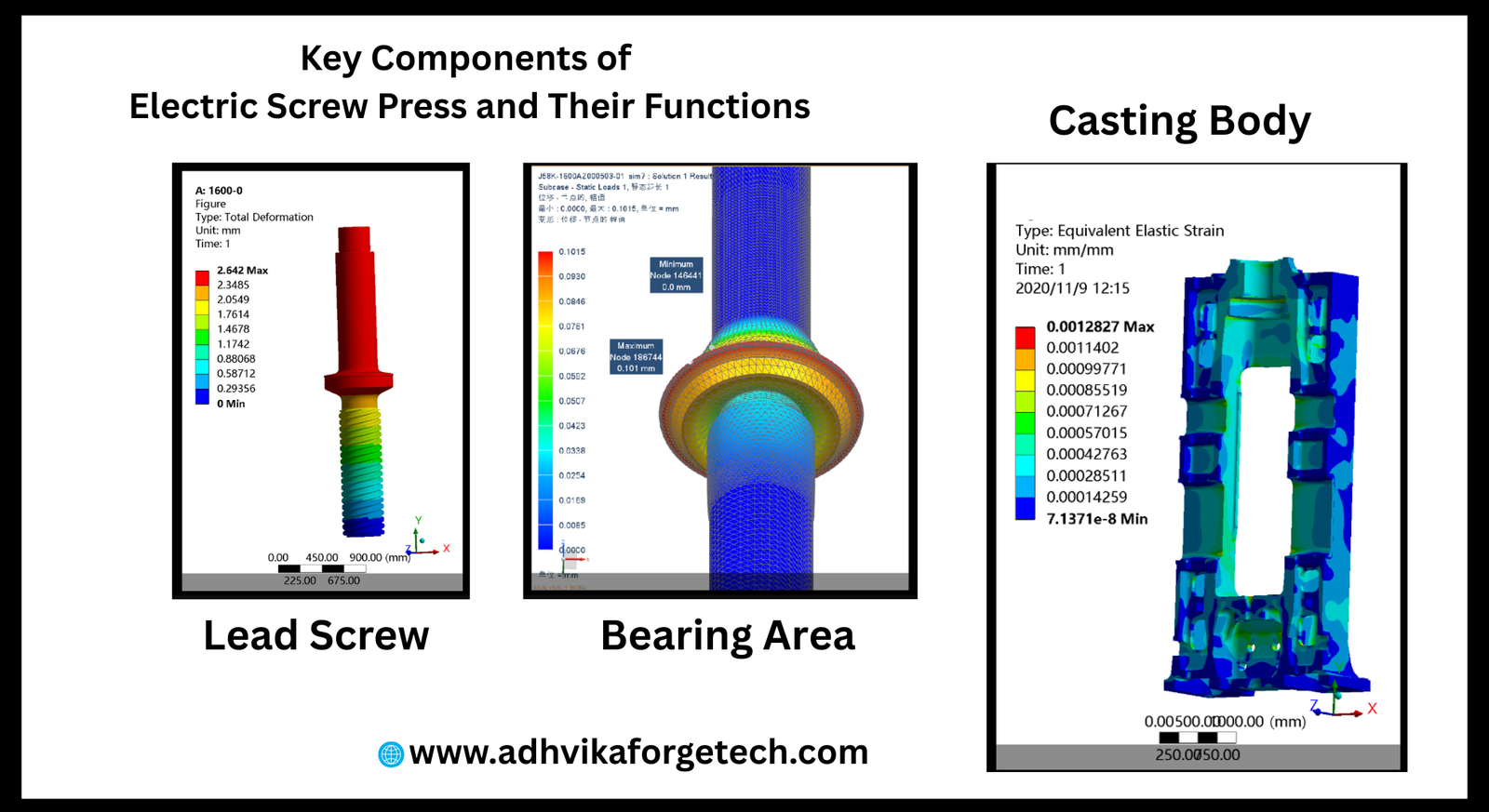

Electric Screw Presses

Engineered for energy efficiency and high accuracy, our electric screw presses provide consistent force and stroke control. They are suited for precision forging operations where repeatability is critical. With fewer moving parts than mechanical presses, they require less maintenance while offering longer service life.

Electric screw press offers precision forging with accurate energy control, strong anti-tilt capacity, and reliable, low-maintenance operation for efficiency.

Turnkey Solutions: From machine selection to commissioning, complete forging line setup under one roof.

Cost-Effective Projects: Low-cost machinery with optimized energy and material savings for faster ROI.

Advanced Technology: Expertise in Electric Screw Press, Ring Rolling, and Automated Forging Lines.

Customized Engineering: Tailored solutions for automotive, aerospace, defense, and industrial applications.

After-Sales Support: On-site training, maintenance, and reliable service with local support teams.

Electric CNC Screw Press

Direct Drive Screw Presses

Our Direct Drive Screw Presses combine high forging force with precise motion control, making them ideal for complex, high-quality metal forming applications. These presses use a direct motor-to-screw connection, eliminating belts or gears for smoother operation, reduced maintenance, and higher efficiency.

With adjustable stroke and energy settings, they provide exceptional flexibility for both hot and cold forging. The direct drive system ensures consistent performance, minimal vibration, and improved tool life, helping manufacturers achieve tighter tolerances and higher productivity.

Whether you are producing automotive components, aerospace parts, or custom precision forgings, our Direct Drive Screw Presses are engineered for reliability, energy savings and long-term operational stability.

Aluminum Alloy Forging Titanium Forging Inconel Forging Duplex Forging

Direct Drive Screw Press

Open Die C-Frame Type Hammers

Our Open Die C-Frame Type Hammers combine the flexibility of open die forging with the accessibility and efficiency of a C-frame design. The open front and side access allow operators to handle larger work pieces with ease, making these hammers ideal for producing custom shapes, oversized parts, and low-volume speciality forgings.

The C-frame structure provides excellent accessibility for tooling changes, quick adjustments, and complex part handling, while the hydraulic system ensures controlled, powerful strikes. Adjustable blow force and stroke settings make it possible to achieve precise shaping with minimal material waste.

Built for heavy-duty industrial use, these hammers deliver durability, ease of maintenance, and reliable performance in demanding applications such as aerospace, shipbuilding, power generation, and large machinery manufacturing.

Open Die C-Frame Type Hammer

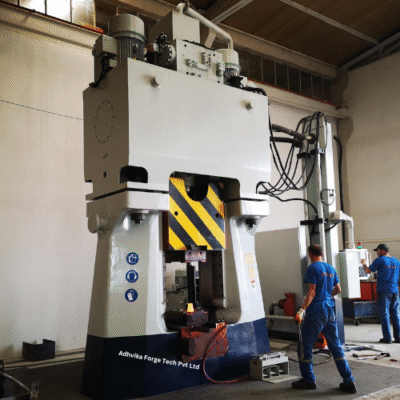

Double Column Hydraulic Hammer – Open Die Forging Industry

The Double Column Hydraulic Hammer is a powerful forging solution for the open die forging industry, designed for heavy-duty operations like forging shafts, rolls, flanges, and large industrial components. Its double column structure ensures superior stability, balanced force distribution, and high rigidity during forging. With precise energy control and a hydraulic drive system, it delivers consistent impact force, reduced vibration, and longer tool life. Suitable for alloy steels, titanium, and stainless steel, it supports upsetting, drawing-out, piercing, and bending operations. Modern versions integrate automation and manipulators, enabling high productivity, energy efficiency, and reliable performance for large-scale forging applications.

At Adhvika Forge Tech, our Double Column Hammer delivers high power, stability, and precision for the open die forging industry. Designed for heavy-duty applications like shafts, flanges, and large industrial parts, it ensures balanced force distribution, reduced vibration, and long tool life. With automation integration and energy efficiency, it offers high productivity, reliable performance, and low maintenance costs for modern forging operations.

“High stability, precise energy control, low vibration, long tool life, and high productivity.”

Double Column Hydraulic Hammer

Hydraulic Press in the Open Die Forging Industry

The hydraulic press plays a critical role in the open die forging industry, offering the force, flexibility, and precision required to forge large, complex components. Unlike mechanical or screw presses that depend on kinetic energy, a hydraulic press uses hydraulic fluid pressure to deliver a controlled and consistent pressing force. This makes it ideal for forging heavy-duty components such as shafts, rolls, flanges, gear blanks, and industrial equipment parts with exceptional accuracy and repeatability.

One of the major advantages of a hydraulic press in open die forging is its programmable pressure and stroke control. Operators can regulate the pressing force at every stage of the forging cycle, ensuring uniform metal flow and superior mechanical properties in the finished component. The ability to maintain constant pressure throughout the stroke allows forging of large cross-section billets without defects, reducing internal stresses and improving metallurgical quality.

“High precision, energy efficient, versatile operations, low maintenance, and long service life.”

Pneumatic Hammer for Open Die Forging

The Pneumatic Hammer is a widely used forging machine in the open die forging industry, offering versatility, simplicity, and cost-effective operation. Powered by compressed air, it delivers high-energy blows for forging operations such as upsetting, drawing-out, bending, punching, shearing, forge welding, and twisting. Its air-driven mechanism allows rapid hammer strokes with adjustable impact energy, ensuring precise control over the forging process.

Pneumatic hammers are compact, easy to maintain, and suitable for small to medium-sized forgings made from carbon steel, alloy steel, and non-ferrous metals. They require less foundation compared to heavy hydraulic presses and are ideal for job shops and medium-scale forging units. The simple design ensures low installation cost, while the quick stroke adjustment enhances productivity. Overall, pneumatic hammers remain a reliable, affordable, and flexible solution for various open die forging applications.

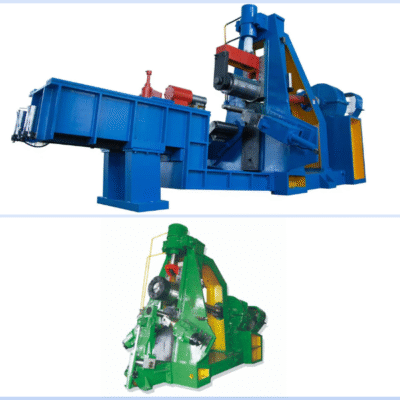

Ring Rolling Machine

The Ring Rolling Machine is a specialized forging equipment designed for producing seamless rolled rings with high precision and material efficiency. Used in aerospace, automotive, bearings, wind power, and oil & gas industries, it shapes pre-forged rings into larger diameters with reduced material waste compared to traditional methods. The process ensures excellent grain flow, improved mechanical properties, and uniform wall thickness. Modern ring rolling machines offer CNC control, automation, and quick changeover for high productivity and accuracy. Capable of producing rings from a few hundred millimeters to several meters in diameter, they deliver energy savings, consistent quality, and cost-effective production for critical industrial applications.

Ring Rolling Machines offer high precision, low material waste, uniform wall thickness, excellent grain structure, and energy-efficient production. Ideal for aerospace, automotive, and industrial applications with consistent quality and cost savings.

CNC Hydraulic Forging Hammer

Our CNC Hydraulic Forging Hammers combine the raw power of hydraulic technology with the precision of CNC control systems. This integration allows for highly accurate, repeatable strikes, making them ideal for producing consistent, high-quality forgings in both small and large batches.

The CNC interface enables programmable strike force, stroke length, and blow sequence, giving operators full control over the forging process. This precision not only improves product quality but also reduces material waste and tooling wear.

Built with heavy-duty frames, high-performance hydraulic systems, and advanced automation capabilities, our CNC Hydraulic Forging Hammers are perfect for industries that demand both strength and precision—such as aerospace, automotive, energy, and custom forging applications.

Forging Servo Screw Presses

Our Forging Servo Screw Presses are engineered for maximum precision, energy efficiency, and process control. Powered by advanced servo motor technology, these presses deliver consistent force and stroke accuracy, making them ideal for precision forging applications where repeatability is critical.

The servo-driven system allows for programmable speed, torque, and position control, ensuring optimal metal flow and minimal material waste. This flexibility makes them suitable for both hot and cold forging, as well as complex part geometries that require tight tolerances.

Compared to traditional presses, our servo screw presses offer lower energy consumption, quieter operation, and reduced maintenance—helping manufacturers achieve higher productivity and lower operational costs. They are widely used in aerospace, automotive, medical, and high-performance industrial sectors.

Our Clients

Adhvika Forge Tech, we take pride in delivering high-quality forging solutions, turnkey projects, and excellent service.

We are committed to delivering the best solutions and building long-term partnerships with our clients.