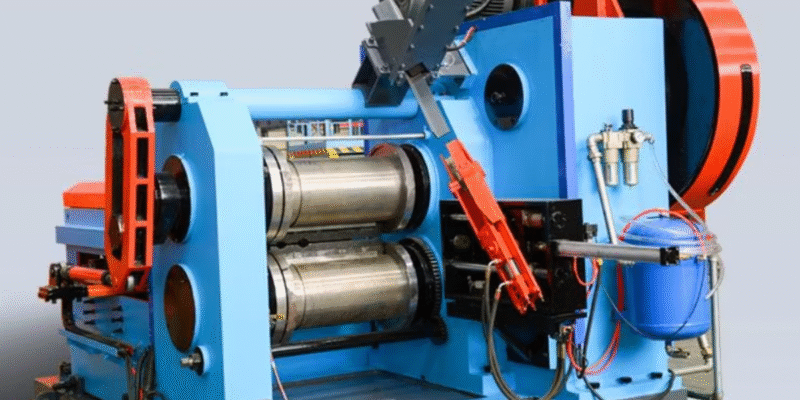

Reduce Roll Machine for Forging Lines – Optimized Preform Sizing with Adhvika Forge Tech

Adhvika Forge Tech, we provide high-efficiency Reduce Roll Machines that are essential in modern forging lines for improving billet shaping and enhancing metal flow before final forging.

These machines are specifically designed for hot billet reduction to achieve the required dimensions before close die or open die forging—ensuring consistency, better grain structure, and cost-saving on raw materials.

⚙️ Why Choose Reduce Roll Machines?

✅ Improved Grain Flow: Ensures directional strength in the final forging

✅ Material Saving: Less wastage and optimized billet weight

✅ Higher Die Life: Reduces stress on final forging dies

✅ Flexible Operation: Suitable for shafts, axles, ring preforms, and long bars

✅ Custom Configurations: Available in 2-roll, 3-roll, and 4-roll designs

🛠️ Adhvika Forge Tech Supply Scope:

Fully Assembled Reduce Roll Machine

Hydraulic or Mechanical Drives

Electrical Controls with Safety Systems

Integration with Screw Press, Hammer, or Ring Rolling Line

Commissioning, Training, and AMC Support

Adhvika Forge Tech supplies Reduce Roll Machines for forging preforms. Ideal for shafts, axles & ring blanks. Increases grain flow, reduces material cost & enhances final forging quality.

#ReduceRollMachine #ForgingSolutions #ForgingAutomation #MetalForming #PreformSizing #OpenDieForging #CloseDieForging #AxleForging #ShaftForging #ForgingIndustry #AdhvikaForgeTech #RollingMachine #BilletReduction #RingRollingPrep