Forging Conversion Cost: Key Factors, Optimization & Cost-Saving Strategies

Forging is a highly efficient manufacturing process, but understanding and controlling forging conversion cost is crucial for profitability and competitiveness. Whether in open die forging, closed die forging, or ring rolling, conversion cost plays a pivotal role in determining the final product price and ROI.

Click Here More Forging Machine & Services Adhvika Forge Tech

What is Forging Conversion Cost ?

Forging conversion cost refers to the total expense incurred in transforming raw materials into a finished forged component. It includes:

✅ Material Cost – Raw material wastage, scrap utilization, and input weight.

✅ Energy Cost – Electricity, gas, or fuel required for heating and forging.

✅ Labor Cost – Skilled manpower for operating forging machines and finishing.

✅ Machine & Tooling Cost – Maintenance, tooling wear & tear, and depreciation.

✅ Overhead Costs – Logistics, quality checks, and process monitoring.

Key Factors Affecting Forging Conversion Cost ?

🔹 Material Efficiency

Using high-yield materials and optimizing billet size can reduce scrap rates and minimize waste. Advanced ring rolling and precision forging techniques help lower excess material usage.

🔹 Energy Optimization

Adopting Electric CNC Screw Presses with inverter drives (such as those provided by #adhvikaforgetech) can significantly reduce energy consumption. Energy-efficient induction heating systems also help in cost savings.

🔹 Tooling & Die Life

Well-designed dies with optimized wear resistance can improve production life cycles and reduce frequent replacements, lowering per-unit costs.

🔹 Automation & Robotics

Implementing automated handling, trimming, and forging processes enhances production rates while reducing dependency on manual labor.

🔹 Process Optimization

Fine-tuning forging temperature, press settings, and cooling cycles can improve efficiency and reduce rework, leading to cost savings.

Strategies to Reduce Forging Conversion Cost ?

🚀 Invest in Low-Cost Forging Machines

Using high-efficiency forging presses that offer precision control and minimal downtime improves productivity and reduces cost per piece.

⚙️ Implement Smart Maintenance

Predictive maintenance using AI and IoT sensors can prevent unexpected breakdowns and reduce machine downtime.

🌍 Optimize Supply Chain & Logistics

Sourcing raw materials locally and reducing transit time can cut down overhead expenses.

📉 Reduce Rejections & Rework

Stringent quality control and advanced simulation software can minimize defects, ensuring first-time-right production and reducing overall costs.

Final Thoughts

Reducing forging conversion cost is a strategic approach that requires a balance between efficiency, automation, and cost-effective resource utilization. By implementing modern forging solutions, energy-saving presses, and smart process optimization, manufacturers can enhance profitability while maintaining high-quality standards.

Need expert guidance on optimizing your forging conversion cost? 🔥 Adhvika Forge Tech offers turnkey forging solutions, low-cost press machines, and consultancy services for industries worldwide.

📩 Contact us today! #adhvikaforgetech

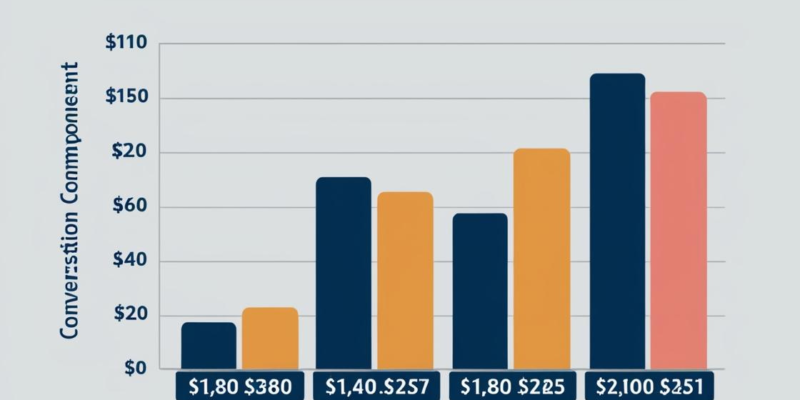

Graph Ideas for Your Forging Projects Report:

1️⃣ Production vs. Cost Graph – How production output affects overall cost.

2️⃣ Machine ROI Timeline – Investment vs. return over time.

3️⃣ Energy Savings with Advanced Presses – Comparing traditional vs. modern forging machines.

4️⃣ Material Efficiency Analysis – Scrap reduction & yield improvement.

5️⃣ Turnkey Project Cost vs. Profitability – How full-line solutions impact ROI.