Explore how automated Trimming Press solutions streamline production and improve output in industrial settings.

Trimming Press

Trimming Press : Overview

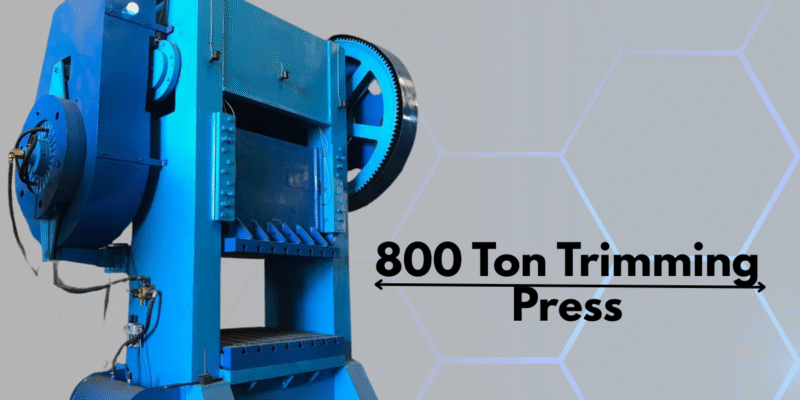

A Trimming Press is an essential machine used in manufacturing processes to remove excess material—such as flash, burrs, or remnants from castings or formed parts—ensuring a clean, precise finish. These presses are commonly employed in industries like automotive, aerospace, medical devices, and general manufacturing to work with materials like metal, plastic, or wood.

Types of Trimming Press Machines

Hydraulic Trimming Press

Operation: Utilizes hydraulic power to generate high force, ideal for heavy-duty trimming tasks, especially with tough materials like metal.

Capacity: Ranges from 20 to 800 tons.

Features:

Customizable dimensions for varied production needs.

Tilting platens for easier material handling.

Integrated scrap conveyors for efficient waste management.

Applications: Suitable for trimming tough materials in high-demand sectors.

Provided by Adhvika Forge Tech.

Pneumatic Trimming Press

Operation: Uses compressed air to power the press, offering faster cycle times suitable for medium-duty tasks.

Applications: Ideal for industries requiring faster but not overly heavy-duty trimming.

Capacity: Typically medium-sized tasks.

Provided by Adhvika Forge Tech.

Manual Trimming Press

Operation: Operated manually, often by hand, making it ideal for smaller, less demanding jobs or in smaller workshops.

Applications: Suitable for crafting or low-volume work, such as button or leather crafting.

Capacity: Low volume, used in specialized or artisan tasks.

Provided by Adhvika Forge Tech.

Servo-Driven Trimming Press

Operation: Features high precision and energy efficiency, providing a faster cycle time and lower energy consumption compared to traditional presses.

Benefits:

Up to 30% faster production speed.

50-70% less energy consumption, making it a cost-effective solution.

Applications: Excellent for high-precision jobs in advanced manufacturing sectors.

Provided by Adhvika Forge Tech.

Key Applications of Trimming Press Machines

Metal Deburring: Used for removing flashes from aluminum, magnesium, or zinc castings in die-casting processes.

Automotive and Aerospace: Ideal for cutting and shaping materials to make parts like automotive components, aerospace fittings, and medical devices.

Crafting: In smaller-scale applications, such as cutting leather, fabric, and button work.

Construction Materials: Trimming materials like insulation or composite sheets for various building applications.

Key Features of Trimming Press Machines

Customizable Designs: Available in different structural forms like four-column or mono frame designs, tailored to specific production needs.

Precision: High precision with positioning accuracy as fine as ±0.01mm.

Durability: Constructed with high-quality materials, including low-carbon steel and chrome-plated columns for enhanced durability.

Safety: Equipped with essential safety features, including emergency stops, guards, and compliance with safety standards like CE and OSHA.

Automation Integration: Many models can be integrated with robots or automated systems to improve overall efficiency and production rates.

Provided by Adhvika Forge Tech.

Top Manufacturers of Trimming Presses

Adhvika Forge Tech: Known for offering customizable trimming press solutions with advanced features like tilting platens and automated scrap management.

Adhvika Forge Tech: Focuses on precision and integration of safety features, providing a range of trimming press options.

Adhvika Forge Tech: Specializes in offering high-quality hydraulic trimming presses for varied industrial needs.

Adhvika Forge Tech: Offers a comprehensive range of trimming presses, including options with automation and high precision.

This overview encapsulates the functionality, types, features, and applications of Trimming Press machines, provided by Adhvika Forge Tech, helping industries understand their significance in achieving high-quality finishes in manufacturing.