Introduction

Closed die forging, also known as impression die forging, is a widely used forging process in the manufacturing industry. It involves shaping metal using high pressure within specially designed dies. This method is popular in automotive, aerospace, defense, and heavy machinery sectors for producing high-strength components with complex geometries.

What is Closed Die Forging ?

Closed die forging is a process where heated metal is placed between two dies that contain the desired shape. When the dies come together under extreme pressure, the metal flows into the die cavities, taking the shape of the impression. Excess material, known as flash, is trimmed off after forging.

Advantages of Closed Die Forging

- High Strength and Durability: The grain structure of the metal is refined, improving strength and resistance to fatigue.

- Precision and Consistency: Ideal for complex shapes with tight tolerances.

- Material Efficiency: Less waste compared to machining from solid billets.

- Cost-Effective for Large Volumes: Reduced production costs in mass manufacturing.

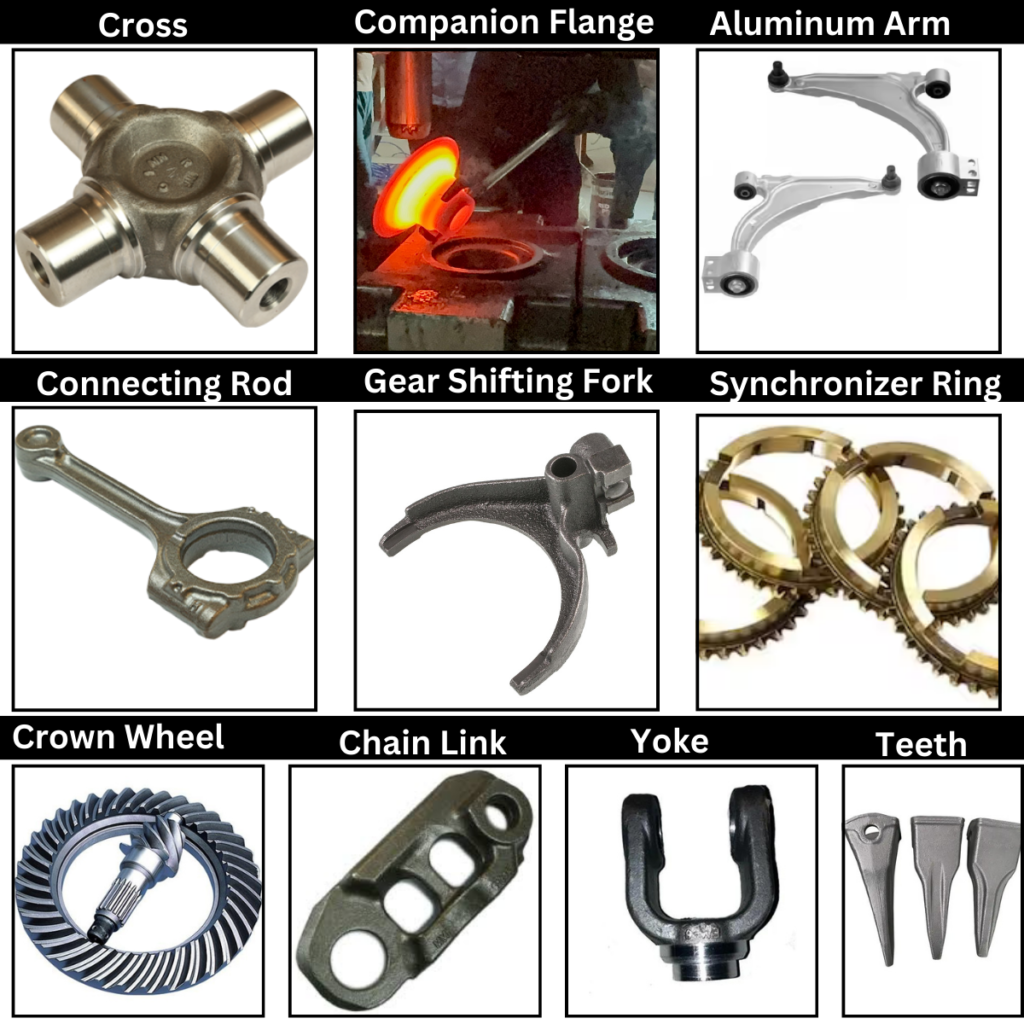

Applications of Closed Die Forging

- Automotive Components: Gears, crankshafts, connecting rods, and axle parts.

- Aerospace Parts: Landing gear components, turbine blades, and structural parts.

- Defense Equipment: High-strength fasteners, weapon parts, and armor components.

- Industrial Machinery: Shafts, flanges, couplings, and bearing housings.

Closed Die Forging Process Steps

- Die Design and Preparation: Precision dies are crafted based on the product’s design.

- Heating the Metal: The metal billet is heated to enhance malleability.

- Forging: The heated billet is placed in the die, and high-pressure force is applied.

- Trimming: Removing excess material (flash) for a clean finish.

- Heat Treatment: Enhancing mechanical properties like hardness and strength.

- Finishing Operations: Machining or surface treatments for final specifications.

Why Choose Adhvika Forge Tech for Closed Die Forging Solutions ?

At Adhvika Forge Tech, we specialize in providing turnkey solutions for closed die forging industries. Our expertise includes:

- Low-Cost Forging Machines: Energy-efficient and designed for high productivity.

- Project Management: End-to-end solutions from concept to commissioning.

- Tooling Design: Advanced tooling for precision and durability.

- Global Reach: Trusted by clients worldwide for forging consultancy and services.

Conclusion

Closed die forging is a versatile and efficient process for producing high-quality metal components. Whether you’re in the automotive, aerospace, or industrial sector, Adhvika Forge Tech offers comprehensive solutions tailored to your needs. Contact us today for expert guidance and cost-effective forging solutions.

#AdhvikaForgeTech #ForgingSolutions #ClosedDieForging #ForgingMachines