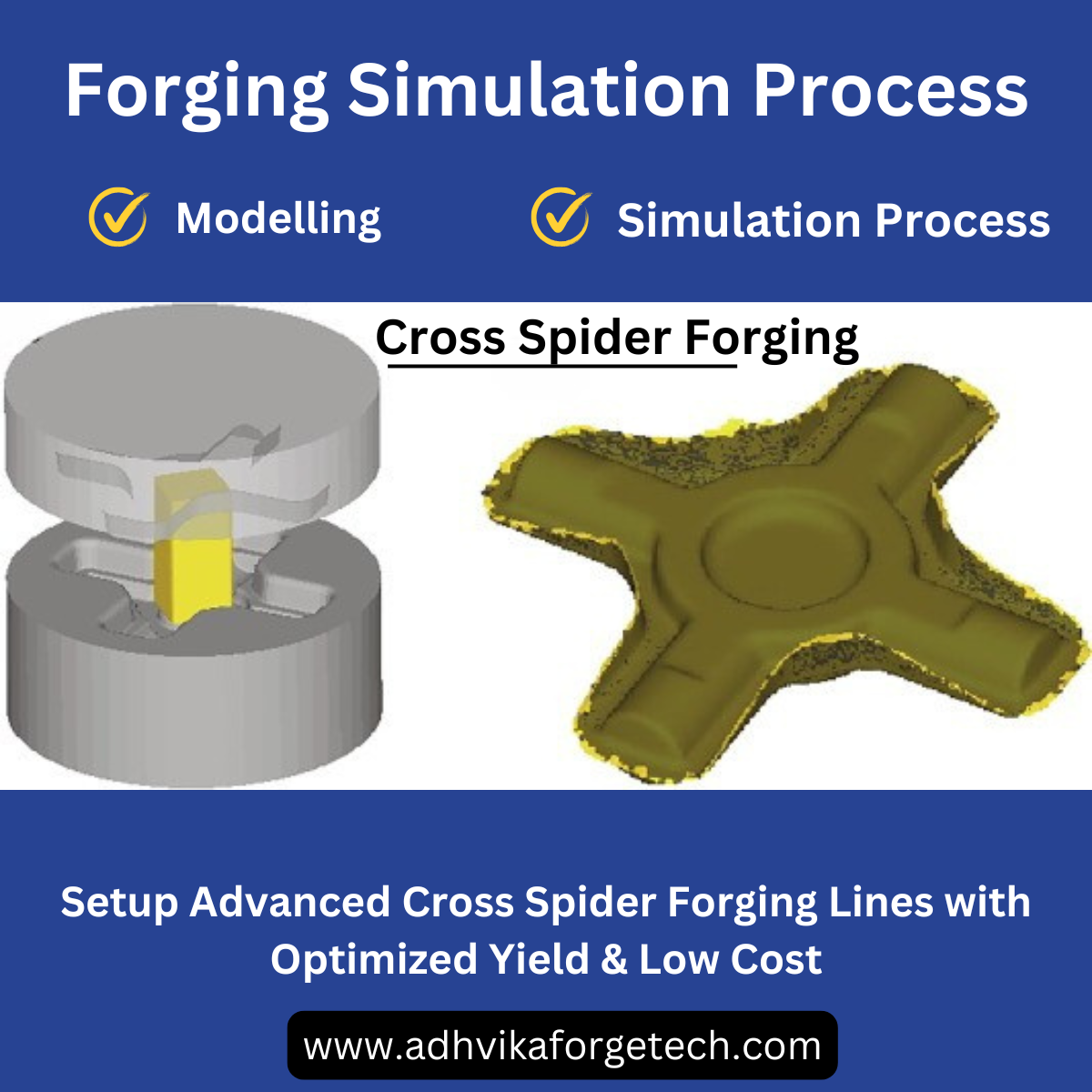

Spider Forging | Cross Forging | Yield Improvement

Adhvika Forge Tech, we specialize in setting up advanced Cross Spider forging lines with precision engineering.

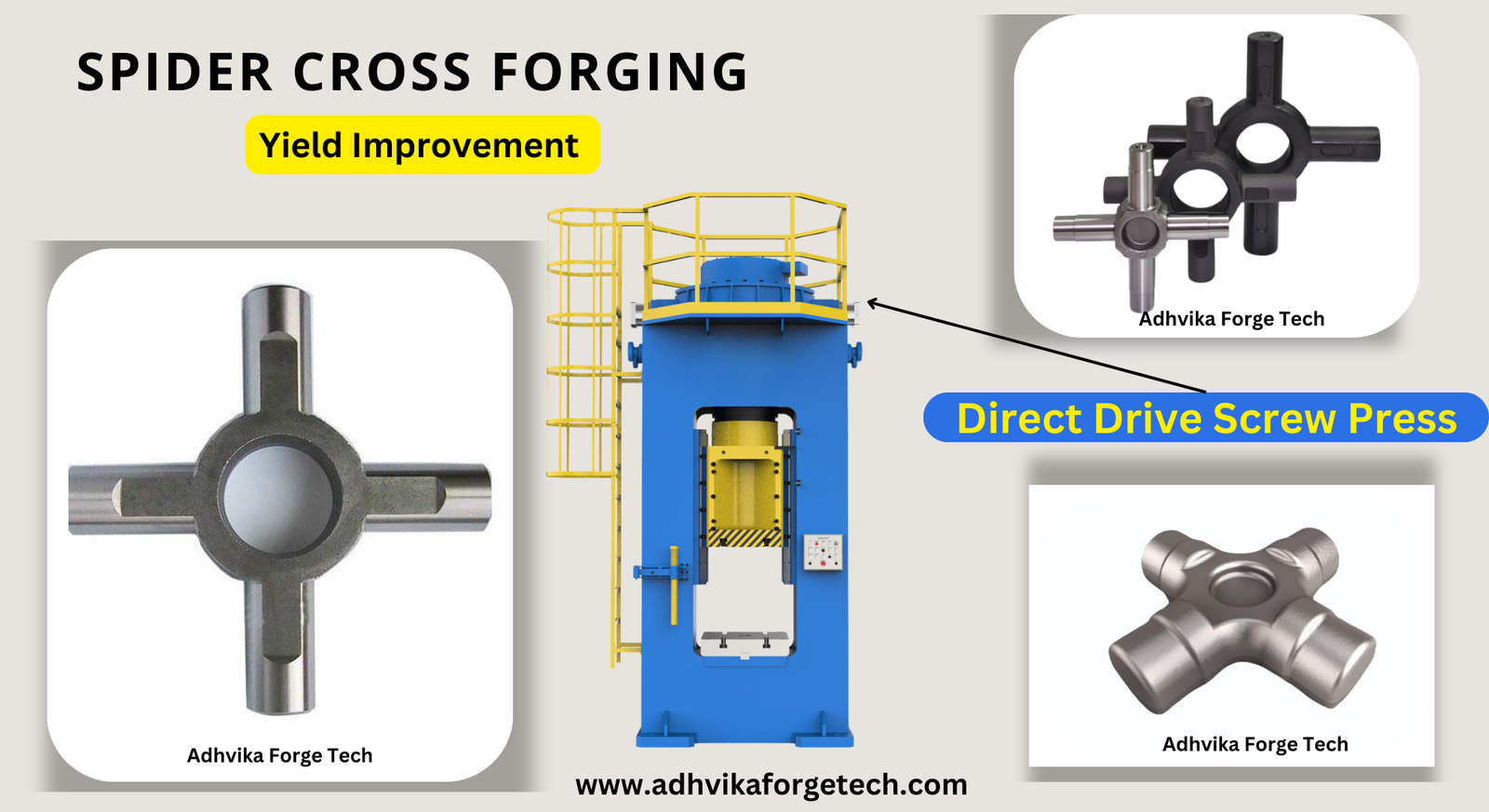

Our expertise includes Electric Screw Press solutions and complete turnkey project execution, ensuring cost-effective and high-efficiency forging setups.

We provide end-to-end support, from machine installation to production optimization, delivering cutting-edge forging solutions for the automotive and industrial sectors.

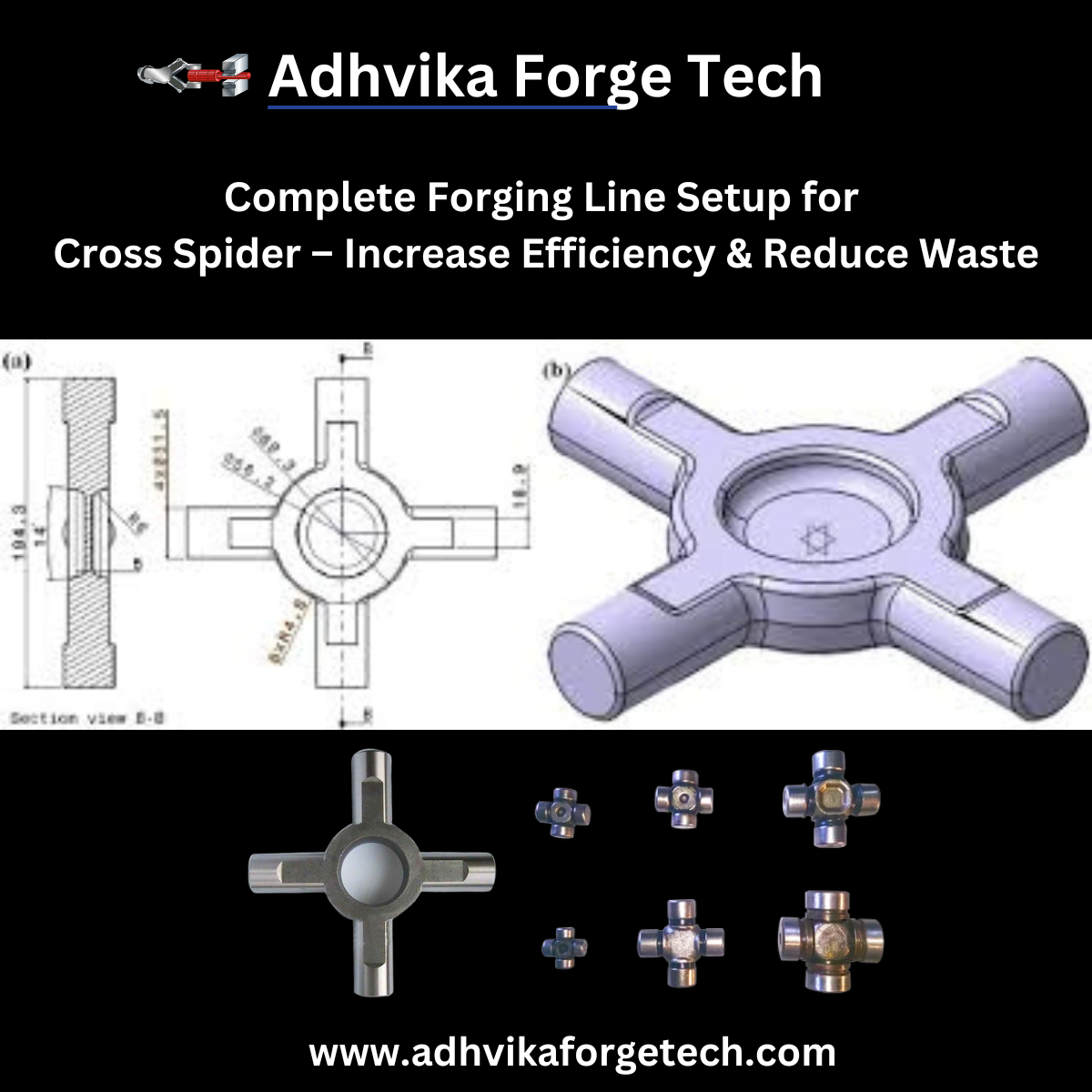

Complete Cross Spider Forging Line Setup – Advanced & High-Efficiency Solutions

How to Improve Yield in Spider Cross Forging?

Enhancing yield in Spider Cross Forging involves optimizing material usage, die design, and forging parameters. Here are key methods:

1️⃣ Use of RCS Billet (Round Cornered Square Billet)

Switching from circular to RCS billets improves material flow.

Aligning the diagonals of RCS billets parallel to the arms enhances metal distribution.

2️⃣ Optimized Die Design

Modify die cavities to allow smoother material flow into spider arms.

Introduce a choke after the flash land to minimize material wastage.

3️⃣ Multi-Stage Forging Approach

Implementing a three-stage forging process (Upset → Blocker → Finisher) improves die filling.

Reduces flash formation and enhances final yield.

4️⃣ Simulation & Process Control (DEFORM-3D Analysis)

Using Finite Element Analysis (FEA) ensures accurate material flow prediction.

Helps optimize billet shape, temperature, and forging pressure.

5️⃣ Controlled Material Flow & Flash Reduction

Adjusting billet dimensions and orientation minimizes excess flash.

Ensuring a fully closed bottom die cavity with precise material entry improves efficiency.

Maximizing Yield in Spider Cross Forging – Proven Results

✅ Traditional Circular Billet: 72% Yield

✅ Optimized RCS Billet: 75% Yield