High-Strength Railway Forging Components – End-to-End Solutions for Rail Industry

Railway Forging Technology – Advanced Turnkey Solutions by Adhvika Forge Tech

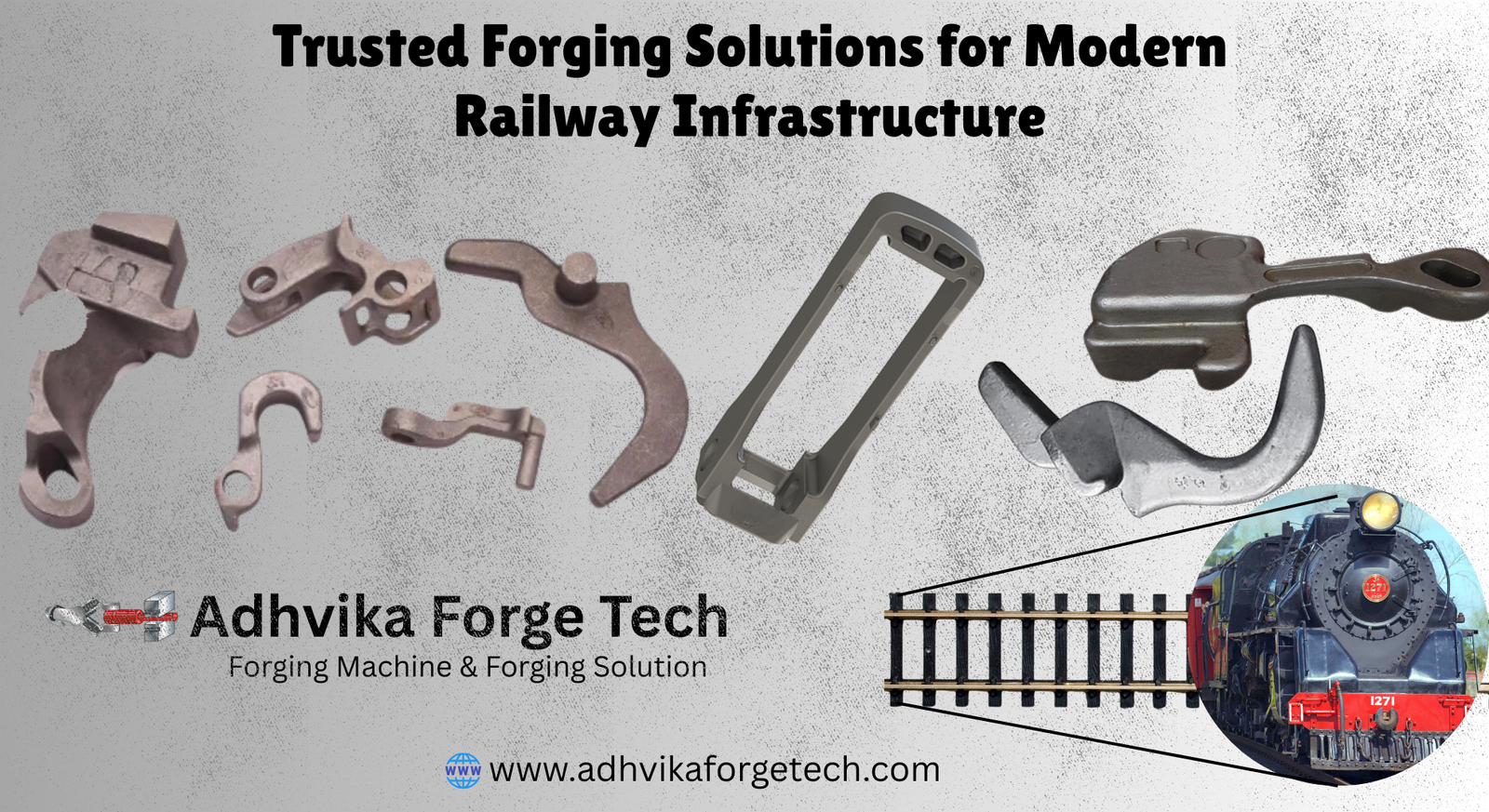

The railway industry demands high-strength, durable, and precision-engineered components to ensure safety, efficiency, and long-term reliability. At Adhvika Forge Tech, we specialize in providing end-to-end turnkey forging solutions tailored for the modern railway sector. Our expertise covers shafts, couplers, axles, and other critical railway components, designed to withstand extreme loads and operational stress.

Our advanced forging technology combines traditional hot forging, precision CNC forging, and automation to produce components with superior mechanical properties, consistent dimensions, and extended service life. Each component undergoes strict quality checks and inspection protocols, ensuring compliance with both domestic and international railway standards.

Why Turnkey Forging Solutions Matter

Turnkey solutions provide a complete, integrated approach to railway component manufacturing. Instead of sourcing machines, designing dies, managing production, and handling post-forging inspection separately, our clients receive a single-window solution that covers:

- Design & Engineering: Optimized CAD/CAE designs for shafts, couplers, and other components.

- Die Manufacturing: Custom dies for precise shaping and reduced material wastage.

- Forging Process Implementation: Hot forging, CNC forging, and precision pressing for superior quality.

- Automation & Handling: Robotic handling, manipulators, and automated workflows for efficiency.

- Inspection & Testing: Dimensional checks, hardness testing, and quality certifications.

By integrating these stages, Adhvika Forge Tech reduces lead time, production costs, and risk, while enhancing the overall performance and reliability of railway components.

Applications in the Railway Industry

Our railway forgings are used in freight wagons, locomotives, metro systems, and high-speed trains. Components like axles, couplers, wheels, and shafts are designed to endure heavy loads, vibration, and continuous operational stress, ensuring the safety and efficiency of rail networks.

Precision & Durability – The Adhvika Advantage

- Material Optimization: Using high-quality alloy steels and other specialized metals.

- Enhanced Mechanical Properties: Forgings with high tensile strength, fatigue resistance, and toughness.

- Consistent Accuracy: CNC forging and precision die design ensure minimal deviations.

- Long Service Life: Components designed to reduce maintenance frequency and downtime.

Global Standards & Compliance

All our railway components comply with Indian Railways and international standards for heavy-duty applications. Our turnkey approach allows clients to achieve repeatable quality, traceability, and regulatory compliance with minimal effort.

Conclusion / Result

Adhvika Forge Tech, we are committed to delivering innovative, reliable, and cost-effective forging solutions for the railway industry. From conceptual design to finished components, our turnkey services enable clients to focus on operations while we ensure precision, strength, and durability in every forged part.

📞 Contact Us: +91-9801329640 | 080-22117198

#RailwayForging #TurnkeyForging #PrecisionForging #RailInfrastructure #HeavyDutyComponents #AdhvikaForgeTech #ForgingSolutions #RailSafety #EngineeringExcellence #DurableComponents #IndianRailway #ForgingRailway #HotForging #CastingIndia #MetalForging #RailwayComponents