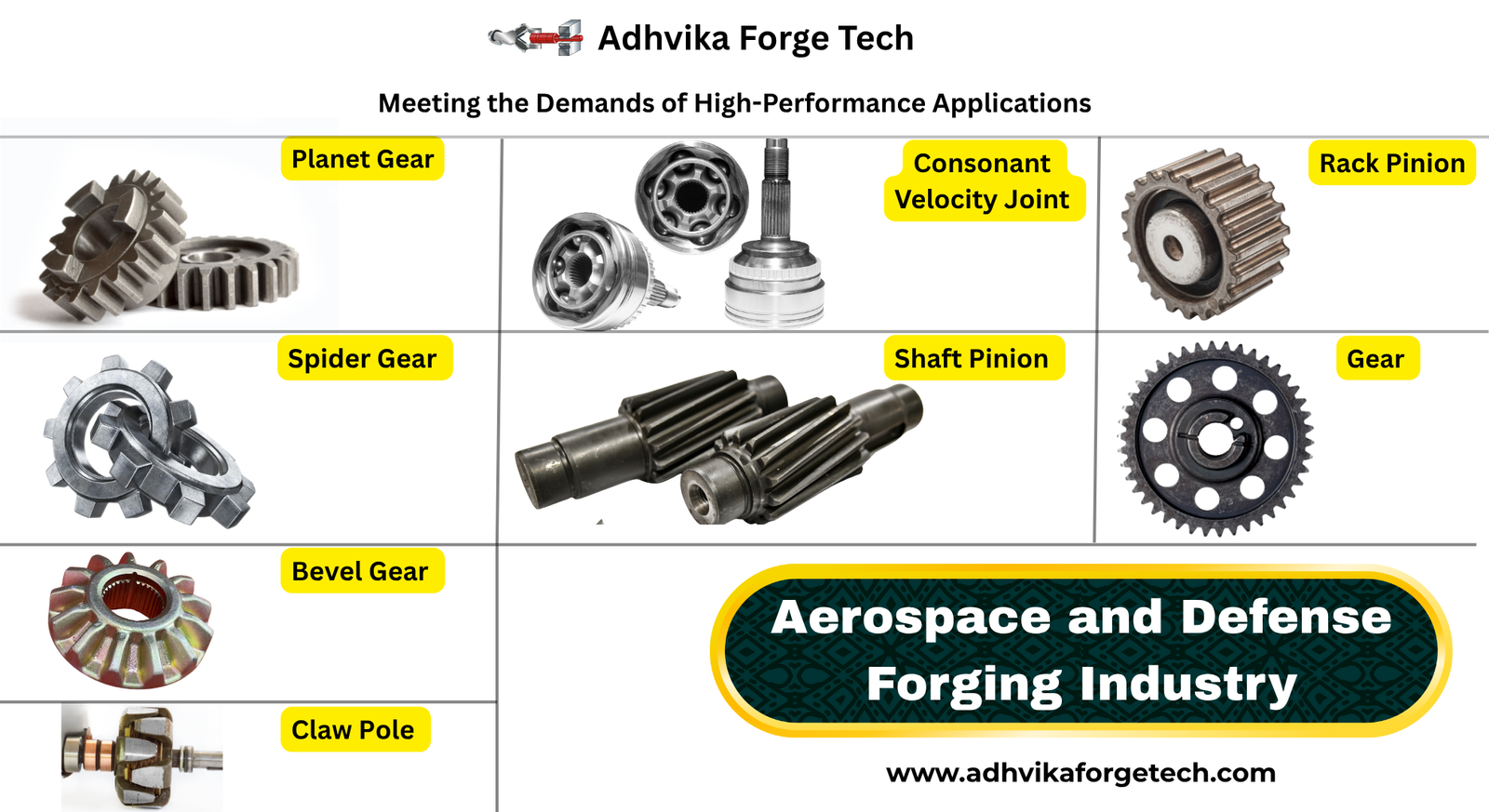

Precision Forging for Aerospace and Defense: High-Performance Component Manufacturing

Adhvika Forge Tech offers end-to-end forging solutions, specializing in aerospace and defense industries. Our precision forging process ensures the creation of lightweight, high-strength components that meet the strict requirements for durability, reliability, and performance. From jet engine components to missile parts and defense vehicle components, we deliver superior parts designed for extreme conditions and demanding applications.

Adhvika Forge Tech delivers precision forging solutions for aerospace and defense industries. We create high-performance, lightweight components like turbine blades, landing gear, and missile parts that meet strict performance standards for strength, reliability, and durability.

Adhvika Forge Tech: Leading the Forging Industry with High-Quality Forging Presses and Comprehensive Forging Services

Adhvika Forge Tech stands as a prominent leader in the forging industry, specializing in manufacturing state-of-the-art forging presses and providing a broad spectrum of forging services to clients worldwide. From manufacturing high-performance forging presses to offering end-to-end services for various industries such as aerospace, automotive, defense, medical, and more, Adhvika Forge Tech continues to redefine excellence in the forging sector.

In this blog, we will delve into the various facets of Adhvika Forge Tech, exploring our expertise, products, services, and the impact we’ve had on the forging industry.

Adhvika Forge Tech: Our Story and Expertise

Founded in 2018, Adhvika Forge Tech has rapidly grown into a trusted name in the forging industry, providing complete forging solutions. The company’s primary mission is to deliver high-quality, cost-effective forging presses and services, all while ensuring precision, reliability, and performance.

The team at Adhvika Forge Tech brings decades of collective experience in forging technology, project management, and manufacturing. With an extensive knowledge base and hands-on experience, we’ve established ourselves as the go-to provider for forging machinery and services, offering both new installations and overhauling services for existing presses.

Our diverse range of expertise spans from open die forging and closed die forging to ring rolling and cold forging solutions. We design and manufacture presses that cater to multiple industrial needs, focusing on energy efficiency, performance, and cost savings. We also provide comprehensive turnkey solutions for forging, which include everything from machine installation to complete production line setups.

Forging Presses: The Heart of Adhvika Forge Tech’s Offerings

At Adhvika Forge Tech, forging presses form the backbone of our product line. Our presses are designed to handle various applications with high precision, durability, and ease of use. Whether you are in the automotive, aerospace, or defense industry, we offer a range of forging presses that meet the most stringent requirements.

Electric Screw Presses

One of our flagship products is the Electric Screw Press. This high-performance press is ideal for both small-scale and large-scale forging operations. What sets our Electric Screw Press apart is its energy-saving features, which help reduce operational costs significantly. The press is designed with an inverter drive system, providing greater control over the forging process and enhancing energy efficiency. It’s perfect for forging delicate and complex components such as aerospace parts, defense components, and medical implants.

Hydraulic Presses

Our Hydraulic Presses are known for their robustness and versatility. These presses are ideal for open die forging and complex die forging applications. They are built to withstand high operational pressures and ensure consistent performance over extended periods. The C-frame design of these presses allows for efficient material handling and ease of use, making them suitable for a wide variety of industries.

Pneumatic & Drop Hammers

Adhvika Forge Tech also manufactures Pneumatic and Drop Hammers for high-impact forging operations. These hammers are particularly useful for manufacturing shaft and flange components in industries such as oil and gas, heavy machinery, and railways. Our pneumatic hammers are designed to reduce maintenance costs while maximizing productivity. These presses can also be integrated with automation systems to ensure consistency and precision in every strike.

Double Column Hammers

For those requiring heavy-duty forging capabilities, we offer Double Column Hammers. These machines provide superior forging power and are ideal for large-scale industrial operations, such as manufacturing gears, heavy machinery parts, and large structural components. The robust design ensures that even the most demanding operations can be handled with ease and precision.

CNC Forging Hammers

Our CNC Forging Hammers combine the versatility of CNC technology with the power of traditional forging. These presses offer the ultimate precision in forging operations, making them perfect for industries that require parts with tight tolerances and consistent quality. Whether you need to forge complex aerospace components or medical implants, our CNC Forging Hammers offer the flexibility and precision required to meet the highest standards.

End-to-End Forging Services: A Comprehensive Solution

At Adhvika Forge Tech, we believe in providing more than just equipment. We offer a complete range of services designed to help our clients at every stage of the forging process, from initial machine selection and design to installation, commissioning, and ongoing maintenance. Our end-to-end services ensure that our clients have all the support they need to achieve optimal results.

Forging Consultancy

One of our key services is Forging Consultancy, where we assist clients in selecting the right machinery, optimizing forging processes, and improving efficiency. With years of experience, our team of experts can guide you through the best practices for your forging operations, ensuring that you achieve maximum yield and minimize waste.

Turnkey Solutions for Forging Lines

Adhvika Forge Tech provides Turnkey Solutions for forging lines. From setting up complete production lines to designing forging dies and implementing automation, we offer a comprehensive package that covers every aspect of forging operations. Whether you are setting up a new forging line or upgrading an existing one, our turnkey solutions provide the perfect balance of cost-effectiveness, efficiency, and reliability.

Machine Installation and Commissioning

Our Machine Installation and Commissioning services ensure that your equipment is up and running quickly and efficiently. We work closely with our clients to ensure that all machinery is installed correctly, and we assist with the initial calibration and testing of machines to ensure everything is operating at optimal performance levels.

Overhauling and Maintenance Services

Adhvika Forge Tech also provides Overhauling and Maintenance Services for existing forging machines. Over time, forging presses can wear out due to constant use. Our team of experts can help extend the life of your machinery by performing detailed inspections, repairs, and upgrades, including machine reconditioning and software updates.

Die Design and Tooling

Our Die Design and Tooling services help clients optimize their forging processes for the production of complex parts. We work with your team to design custom dies that meet the specific requirements of your operations, ensuring high accuracy and improved tool life.

Automation Integration

We are also pioneers in Automation Integration within the forging industry. We provide automated solutions for material handling, die changing, and quality control. By integrating robotics and AI-driven systems into your forging operations, we help improve efficiency, reduce costs, and maintain consistent quality throughout production.

Industries We Serve

Adhvika Forge Tech has a broad portfolio of clients spanning multiple industries. We serve sectors such as:

- Automotive Industry: Providing high-quality components such as shafts, control arms, and gear blanks.

- Aerospace: Delivering precision components like turbine blades, engine parts, and structural fittings.

- Defense: Supplying durable and high-performance components for military vehicles, weapons, and defense systems.

- Medical: Manufacturing specialized components for medical devices, implants, and surgical tools.

- Oil & Gas: Forging heavy-duty components for pipelines, valves, and pressure vessels.

- Railways: Supplying high-strength components for trains, tracks, and signaling equipment.

Why Choose Adhvika Forge Tech?

Adhvika Forge Tech stands apart due to its unmatched combination of expertise, experience, and customer-centric approach. Here’s why businesses worldwide choose us:

- Comprehensive Solutions: From machine manufacturing to full-service support, we provide everything under one roof.

- Global Reach: We serve clients across the globe, delivering exceptional quality and service wherever needed.

- Customization: We offer tailored solutions to meet the unique needs of your business, ensuring optimal performance.

- Quality Assurance: We follow stringent quality control measures to ensure that every part produced meets the highest standards.

- Expert Team: Our team consists of highly skilled engineers, technicians, and consultants with decades of combined experience.

- Customer Support: We offer ongoing customer support to ensure your operations run smoothly, including training, troubleshooting, and routine maintenance.

Why Choose Us ?

Adhvika Forge Tech is more than just a forging press manufacturer. We are a trusted partner for forging solutions, providing high-quality machinery, expert consultancy, and comprehensive services to clients across a wide range of industries. Our commitment to innovation, efficiency, and customer satisfaction sets us apart in the forging industry. Whether you need advanced forging presses, turnkey solutions, or specialized tooling, Adhvika Forge Tech is here to provide you with the best in class.

If you are looking for a reliable forging partner, reach out to us today and let us help you optimize your forging operations. With Adhvika Forge Tech, you can be sure you are investing in the future of forging.

#AdhvikaForgeTech #ForgingPresses #ForgingIndustry #PrecisionForging #TurnkeyForging #ForgingSolutions #AutomatedForging #AerospaceForging #DefenseForging #AutomotiveForging #MedicalForging #ForgingConsultancy #ForgingServices #HighQualityForging