Medical Implant Forging Solutions by Adhvika Forge Tech – Precision Forging for Life-Saving Components

In the evolving world of healthcare, medical implants play a vital role in restoring mobility, improving patient quality of life, and saving lives. These implants—like hip stems, acetabular cups, and femoral heads—must be manufactured with absolute precision, reliability, and strength. Adhvika Forge Tech stands at the forefront of delivering high-quality medical implant forging solutions, enabling global healthcare manufacturers to achieve top-tier standards at competitive costs.

Why Forging Is Essential in Medical Implant Manufacturing

Forging is the process of shaping metal using localized compressive forces. In the medical field, forged implants exhibit:

Higher strength-to-weight ratios

Improved fatigue resistance

Refined grain structures

Enhanced structural integrity

These characteristics make forged implants ideal for orthopedic applications where mechanical reliability is non-negotiable.

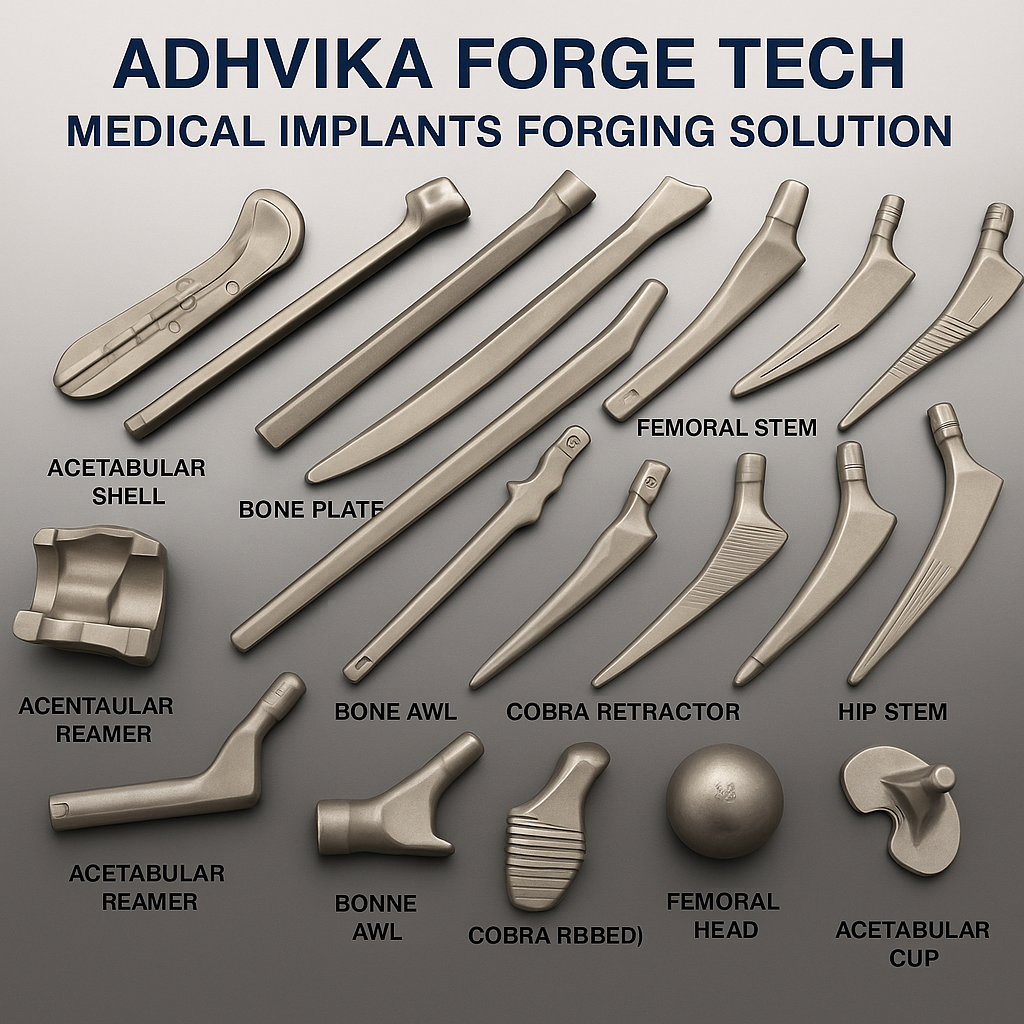

Components We Manufacture Under Medical Forging

Adhvika Forge Tech offers a full spectrum of forged implant components, some of which include:

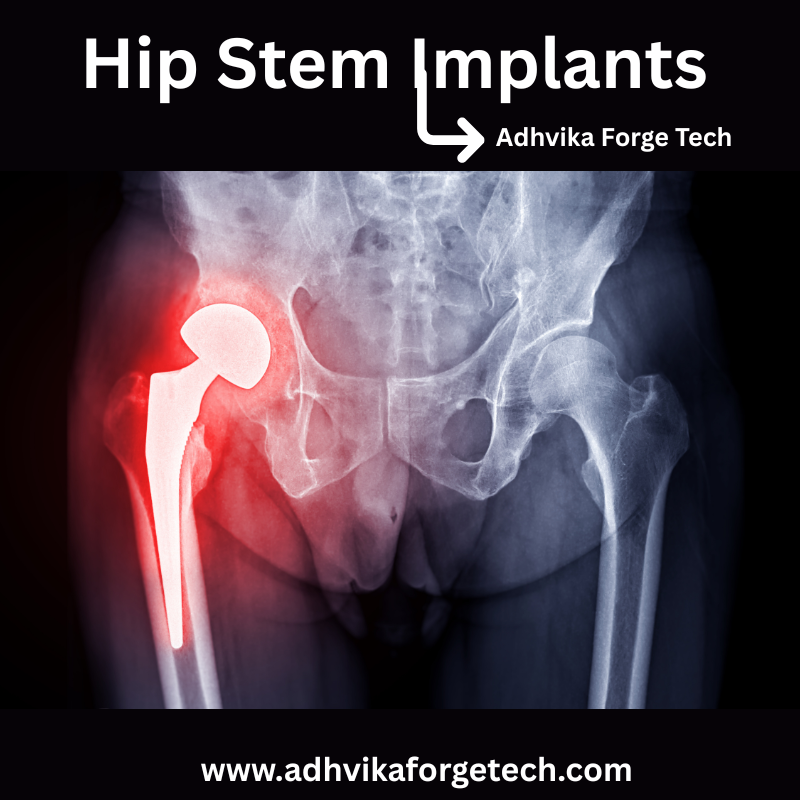

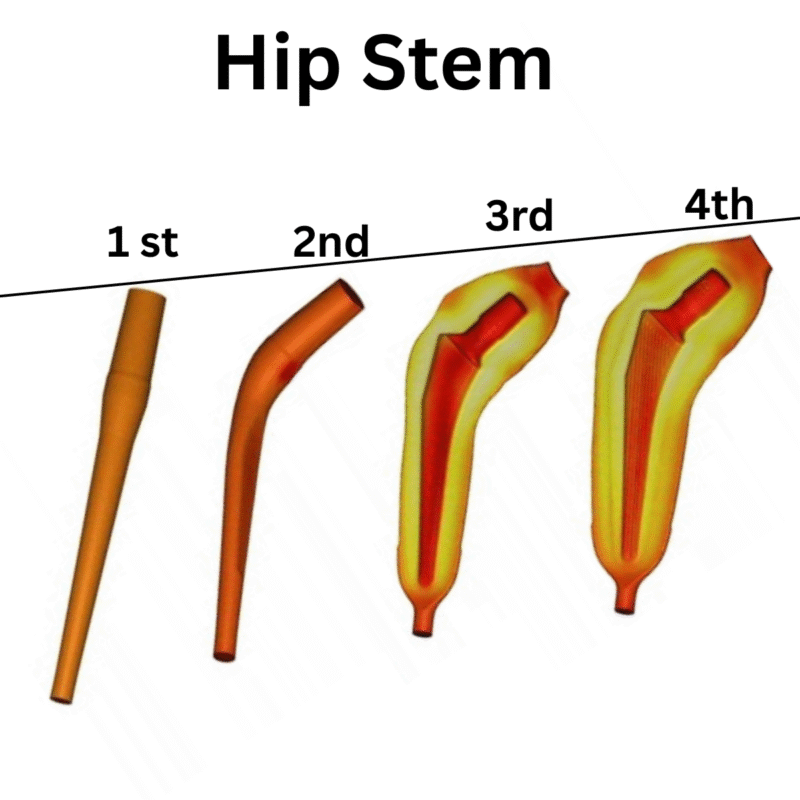

✅ 1. Hip Stem

A core component in total hip replacement surgery, the forged hip stem is inserted into the femur to support the artificial hip joint. Our forging solutions ensure optimal surface finish and fatigue resistance.

✅ 2. Femoral Head

This spherical component articulates within the acetabular cup. We forge femoral heads to precise tolerances to ensure smooth motion and durability over decades.

✅ 3. Acetabular Cup & Shell

These are integral parts of the hip joint replacement, receiving the femoral head. Forged cups and shells provide enhanced wear resistance, corrosion protection, and mechanical stability.

✅ 4. Bone Plates & Bone Awls

Used for trauma implants and orthopedic surgeries, these tools require excellent strength and accuracy. We offer close die forging solutions to manufacture bone plates of various profiles and lengths.

✅ 5. Cobra Retractors & Ribbed Models

Used for orthopedic exposure and surgical access, these are ergonomically forged for surgeons’ ease of use and procedural success.

✅ 6. Acetabular Reamer

Reamers are used for preparing the acetabular cavity in hip surgeries. Our forged reamers provide precision cutting and are compatible with advanced coatings.

Materials We Use in Medical Forging

We forge medical components from industry-certified materials like:

Titanium and Titanium Alloys (Ti6Al4V) – Lightweight, corrosion-resistant, biocompatible

Stainless Steel (316L, 17-4PH) – Cost-effective and strong

Cobalt-Chrome Alloys – Superior wear resistance, ideal for joints

Special Surgical Grade Alloys – Customized as per client requirement

End-to-End Turnkey Support

We don’t just forge — we design, develop, and deliver complete solutions. Whether you’re a startup in the biomedical space or an OEM seeking cost-reduction, we provide:

🏭 Factory layout and equipment selection

🛠 Tooling design and development

🔁 Sample and bulk production trials

📦 Packaging and sterilization support

🌐 Global shipping and after-sales service

🔚 Conclusion: Precision Forging That Heals

In a sector where every micron matters, Adhvika Forge Tech empowers healthcare manufacturers with robust, reliable, and scalable forging technology. From design to delivery, our solutions are crafted to make medical excellence affordable and accessible. Let’s build a healthier world—one forged implant at a time.

Adhvika Forge Tech Pvt Ltd

Call Us : +91-9801329640 / 080-22117198

Email to Us : Info@adhvikaforgetech.com

Website : www.adhvikaforgetech.com