Accurate Forging Weight Calculation: Key Factors and Methods

The forging process is an essential part of many industries, including automotive, aerospace, defense, and industrial manufacturing. Whether you’re producing simple or complex forged components, one of the most crucial aspects to consider is accurately calculating the weight of each forging. This helps manufacturers to estimate production costs, optimize material usage, and ensure precise component specifications. Understanding the different factors involved in forging weight calculation can significantly enhance process efficiency, reduce waste, and ensure quality.

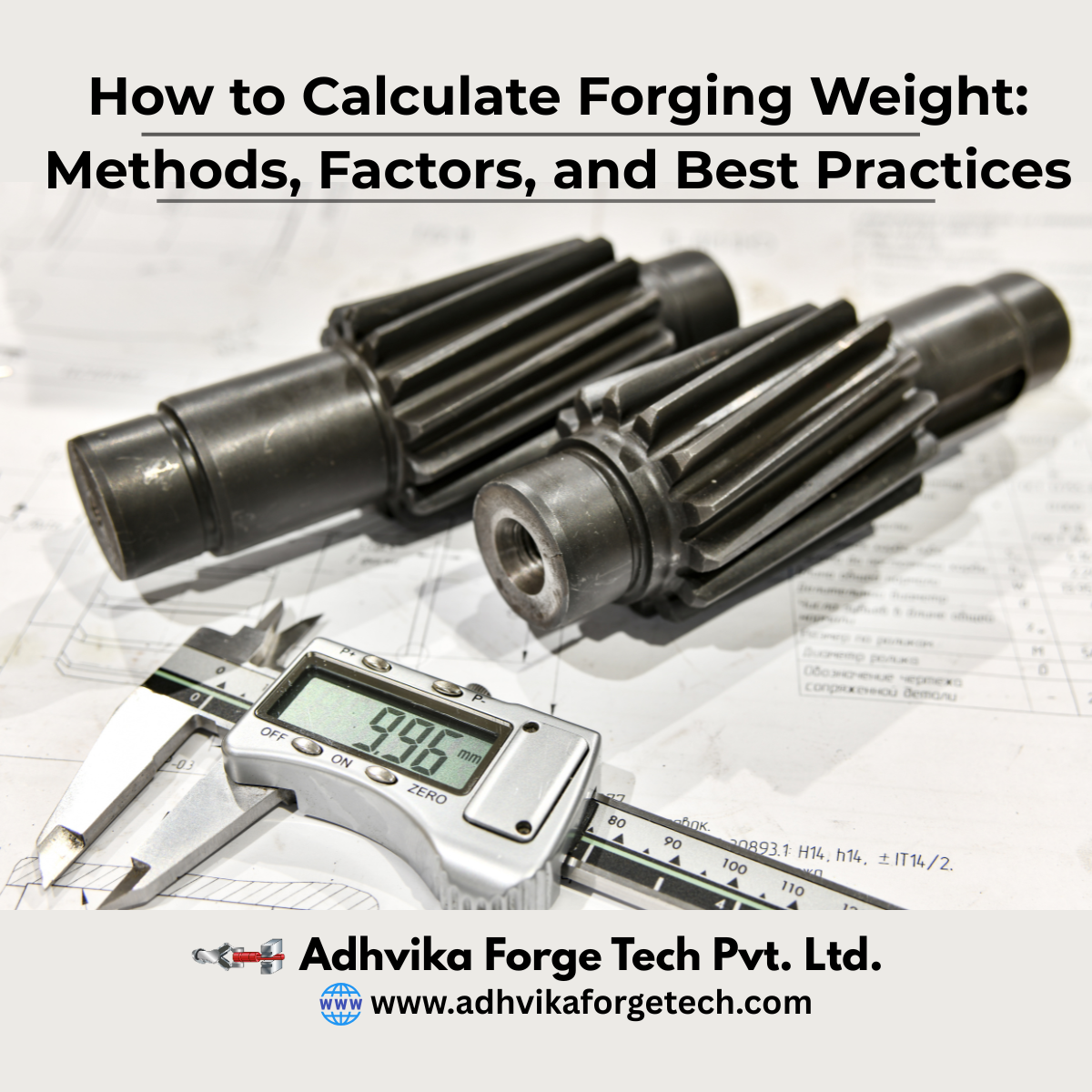

What is Forging Weight Calculation?

Forging weight calculation refers to the process of determining the weight of a forged part, whether it’s a simple or complex shape. This is crucial for several reasons:

Material Efficiency: Calculating the weight ensures you know exactly how much material is required for the forging process, helping in minimizing waste and managing inventory.

Cost Estimation: The weight calculation plays a direct role in determining the cost of raw materials, energy, and labor.

Quality Control: Ensuring that the forged part meets the required specifications in terms of dimensions and weight.

Accurate weight calculation starts from understanding the shape, material properties, and dimensions of the part to be forged.

Factors Influencing Forging Weight Calculation

Material Type:

Different materials have different densities. For example, aluminum alloys are lighter than steel or titanium alloys. This must be taken into account when calculating the weight of the forging.

Shape of the Component:

The geometric shape of the forged component plays a significant role. Simple shapes like disks or shafts are easier to calculate than complex components with varying thicknesses and contours.

Size and Dimensions:

The size of the forging part is directly proportional to its weight. Larger components require more material, and thus, their weight is higher. The dimensions such as length, width, and thickness must be accurately measured.

Forging Process:

Different forging processes, like open-die forging, closed-die forging, or ring rolling, may influence the final weight due to differences in the reduction ratios and material flow.

Shrinkage Allowance:

During the forging process, material shrinks. This shrinkage depends on the material being forged and the process conditions. This must be accounted for when calculating the final weight of the forged product.

Finishing Processes:

Post-forging processes like machining or grinding can remove material from the forged part, which might alter the final weight from the initial forging weight calculation.