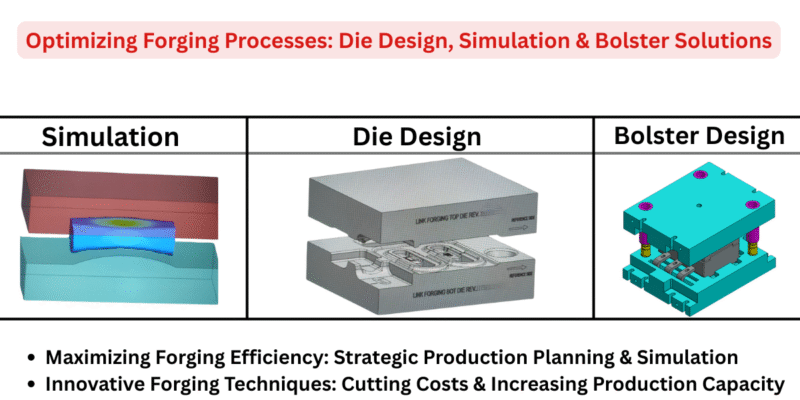

Adhvika Forge Tech offers forging simulation, die & bolster design with cost-cutting solutions, boosting production efficiency and quality output.

Forging Solution Here – Adhvika Forge Tech

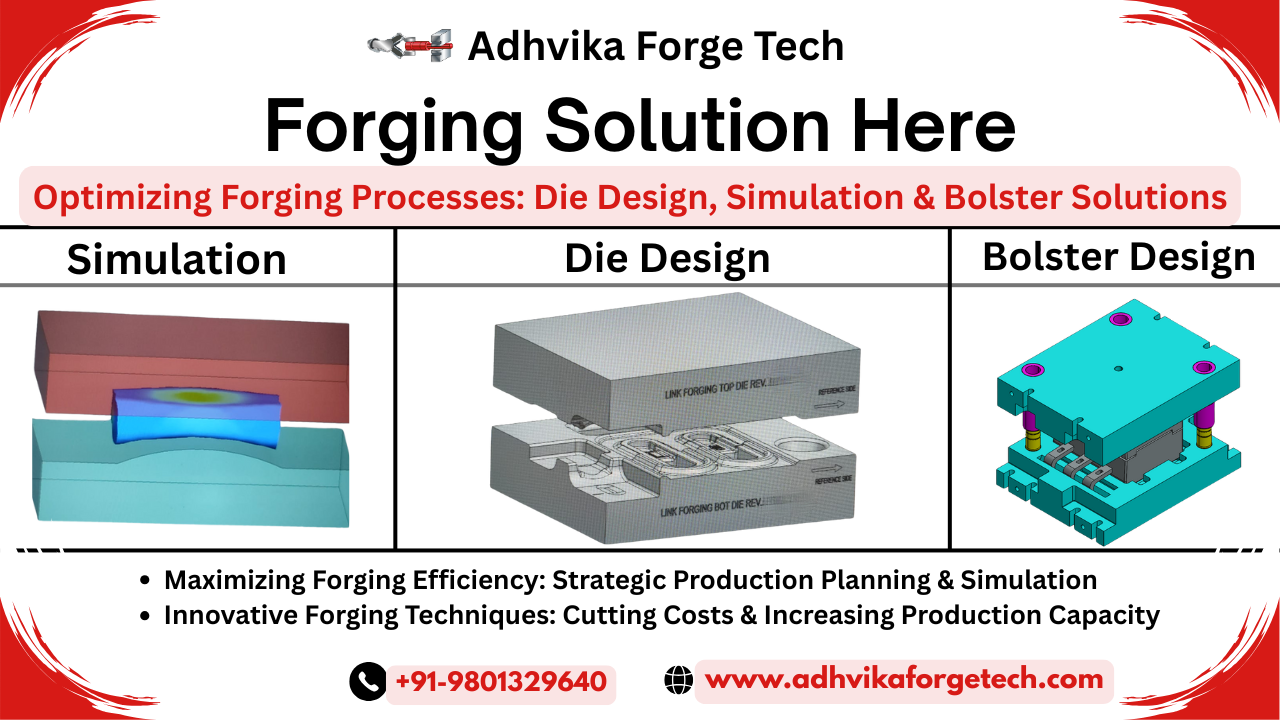

At Adhvika Forge Tech, we specialize in providing end-to-end forging solutions that empower industries to achieve cost efficiency, higher production output, and improved product quality. Our expertise lies in Forging Die Design, Forging Simulation, and Bolster Design, helping clients optimize their forging processes from concept to completion.

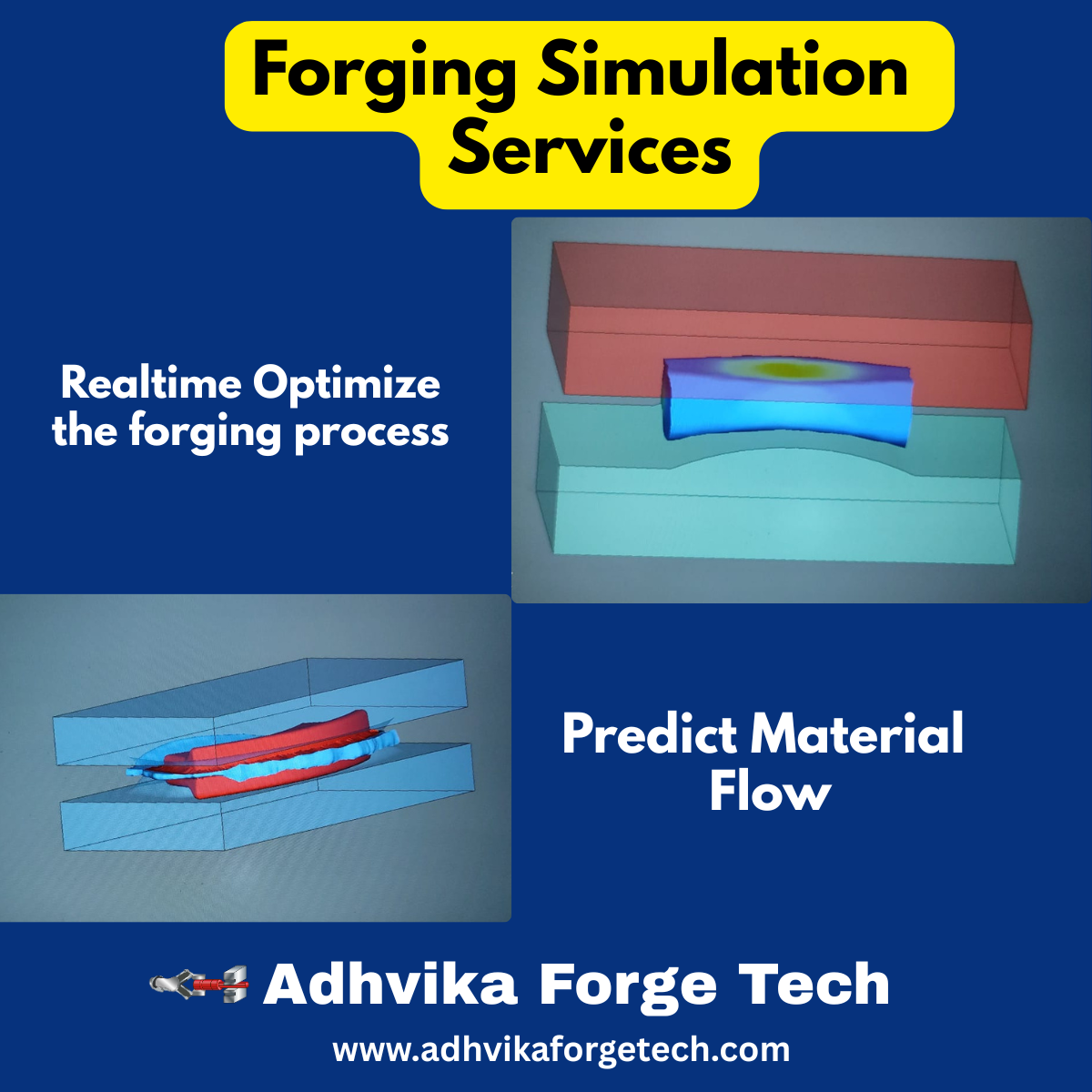

🔹 Forging Simulation

Forging simulation is a crucial step in modern forging technology. Using advanced simulation tools, we predict material flow, detect potential defects, and optimize the forging process before actual production.

✅ Eliminates trial-and-error in production

✅ Reduces scrap and rework, saving time and cost

✅ Enhances die life by analyzing stress and strain distribution

✅ Ensures uniform quality across forged components

With our simulation services, clients can confidently proceed with die manufacturing, knowing that the process is already optimized for best results.

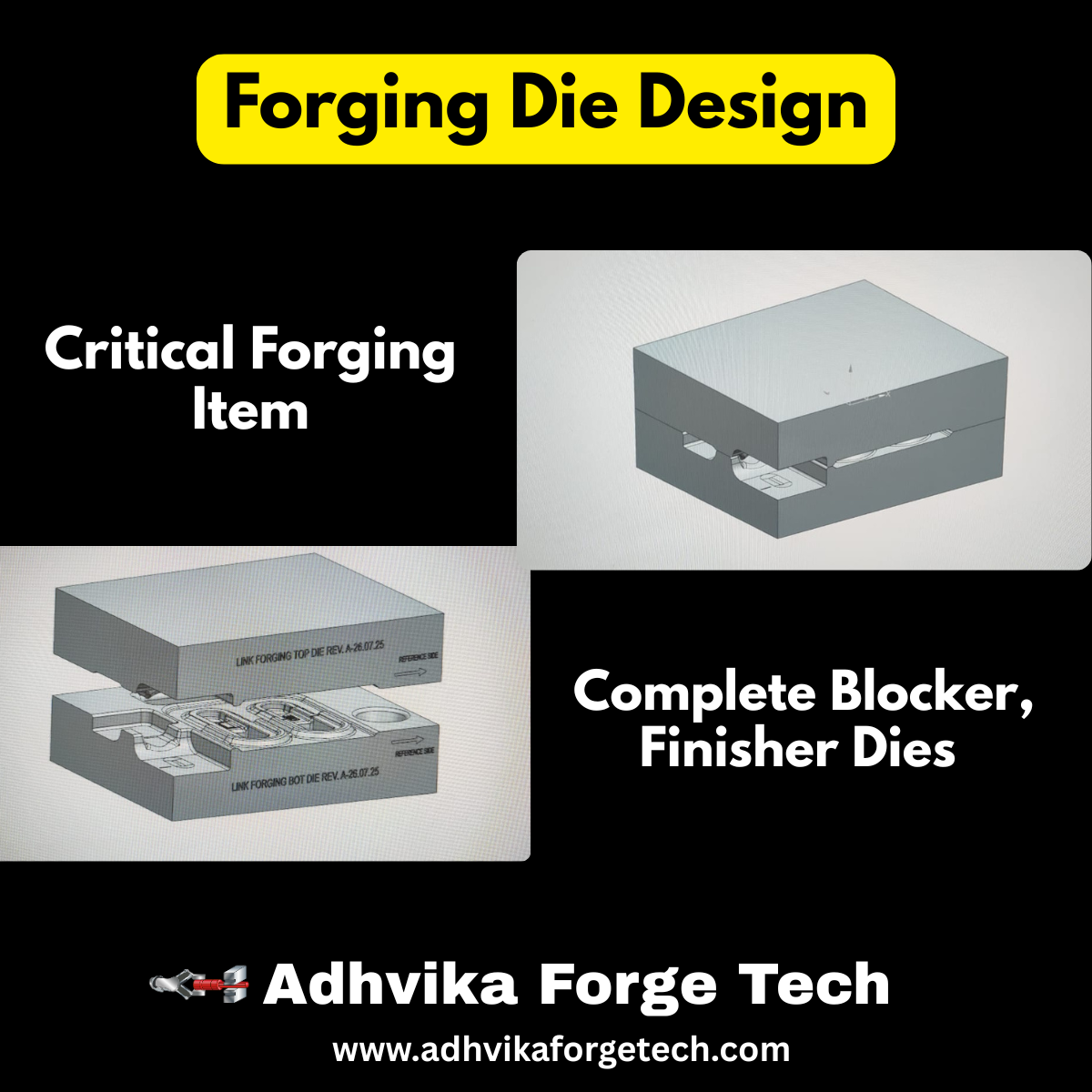

🔹 Die Design

A well-engineered die is at the heart of successful forging. Our team designs forging dies with precision to ensure accurate material flow and longer die life.

✅ Custom die design for various forging applications

✅ CAD/CAM integration for high accuracy

✅ Optimized impression designs for material savings

✅ Reduced cycle times through efficient die configuration

Our designs not only enhance the forging process but also reduce operational costs, leading to higher profitability.

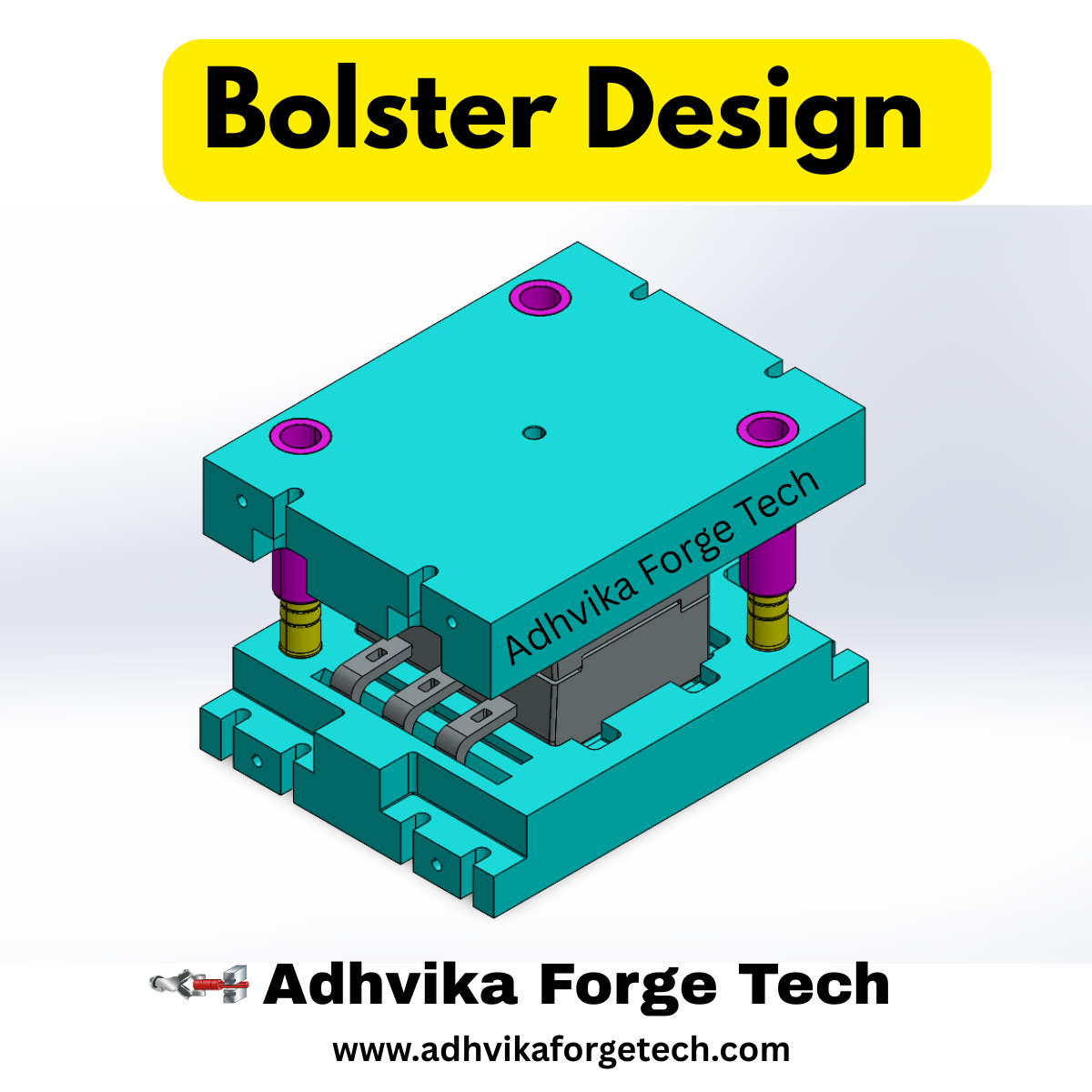

🔹 Bolster Design

The bolster plays a vital role in supporting dies and distributing load during forging operations. Our bolster design solutions are robust, durable, and engineered to handle extreme forging conditions.

✅ Strengthened structures to prevent deformation

✅ Customized designs to fit any forging press

✅ Improved operational reliability

✅ Reduced downtime with easy maintenance features

Our designs ensure safe, efficient, and sustainable forging operations.

🌟 Why Choose Adhvika Forge Tech?

🔧 Expertise: Backed by a team with decades of combined forging experience

💡 Innovation: Cutting-edge simulation and design tools for precision results

💰 Cost Efficiency: Focused on process cost-cutting without compromising quality

🚀 Production Growth: Proven methods to increase production capacity and optimize workflows

🌍 Global Reach: Serving industries worldwide with turnkey forging solutions