Forging Descaling Systems with High Productivity

What is Descaling Machine ?

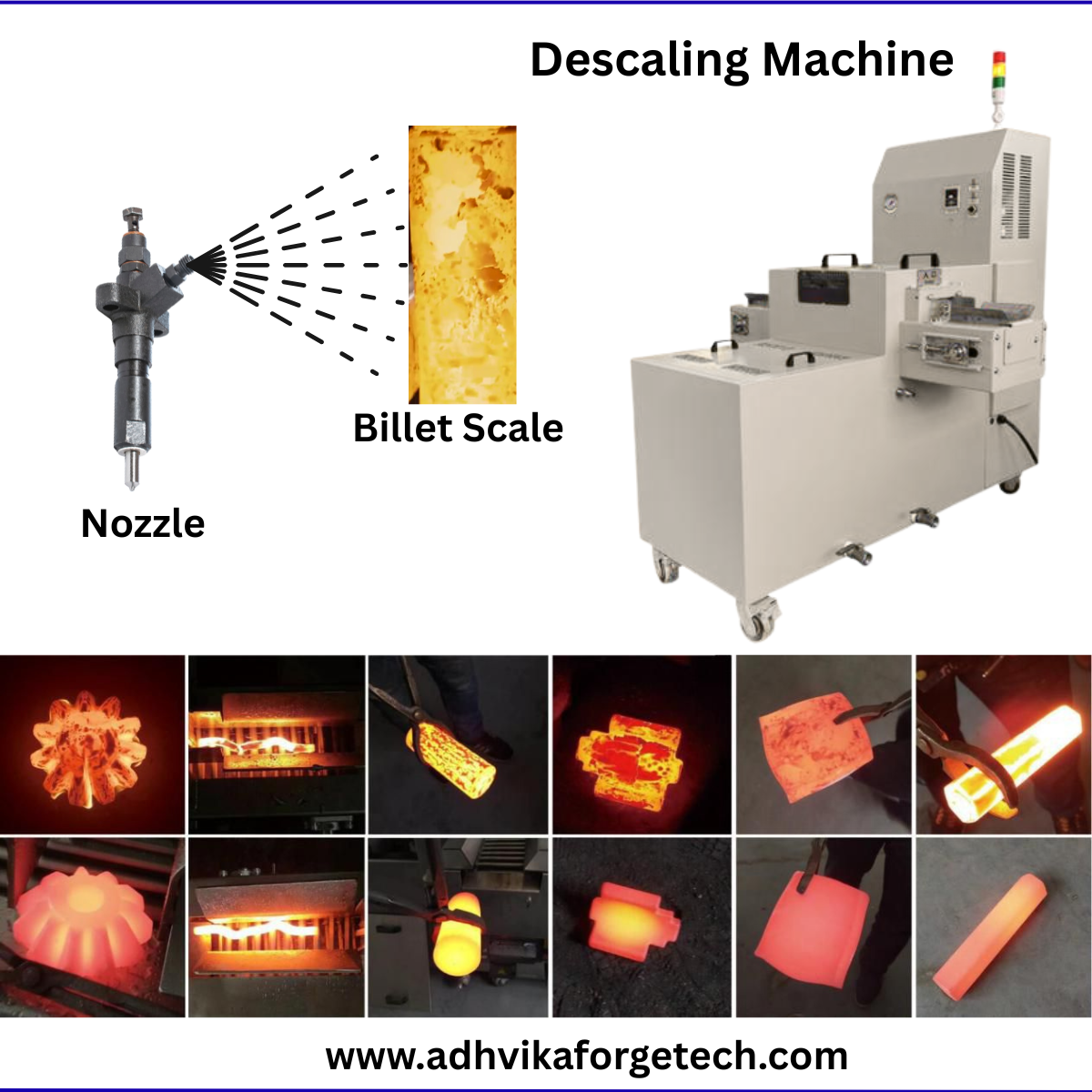

Descaling Machine is used in forging lines to quickly remove oxide scale from hot bars or billets using high‑pressure water, improving surface finish, protecting dies, and reducing waste

Descaling machine is an important part of a forging line. It uses high-pressure water jets to remove oxide scale and impurities from the surface of red-hot bars, billets, or forgings in just a few seconds.

This improves the surface quality of the material, protects forging dies from damage, reduces scrap, and ensures better final product accuracy and finish.

Descaling Machines – Forging Industry Solution by Adhvika Forge Tech

1) Why It’s Needed:

In forging, red-hot billets and bars develop a layer of oxide scale on their surface during heating. This scale, if not removed, can cause poor surface finish, excessive die wear, and scrap during forging. A descaling machine ensures the surface is clean and smooth before forming, protecting dies, reducing defects, and improving product quality. For industries like automotive, aerospace, defense, and heavy engineering, maintaining high surface quality is crucial for precise components.

2) How It Works:

Adhvika Forge Tech descaling machines use high-pressure water jets that strike the hot surface of billets, bars, or forgings at high velocity. The water removes oxide scale, dirt, and other impurities within a few seconds. The machines are designed for continuous forging lines, handling various materials such as steel, alloy steel, aluminum, titanium, and nickel-based alloys. Adjustable water pressure and nozzle arrangements ensure effective descaling for different sizes and shapes of components.

3) Key Benefits:

Improved Surface Finish: Clean billets prevent defects in the final forged products.

Die Protection: Removing scale reduces friction and wear, extending die life.

Reduced Scrap: Defect-free material reduces wastage and increases yield.

High Productivity: Fast operation ensures minimal downtime in forging lines.

Versatile Application: Suitable for shafts, flanges, rings, billets, and complex components.

Energy Efficient: Optimized water consumption and modern pump technology save energy.

4) Typical Specifications:

Material Handled: Steel, Alloy Steel, Aluminum, Titanium, Nickel Alloys

Billet Size Range: 20mm – 400mm (customizable)

Water Pressure: 50 – 150 bar (adjustable)

Machine Length: 2m – 8m (based on line configuration)

Operation: Fully automatic or semi-automatic, integrated into forging lines

Control: PLC-controlled system with safety interlocks

Capacity: 1 – 10 tons/hour, depending on billet size and line speed

Adhvika Forge Tech manufactures a wide range of descaling machines tailored for the forging industry. Whether it’s hot forging of shafts, flanges, rings, or billets, our machines provide precise, reliable, and high-efficiency descaling solutions. Designed for continuous production, our descaling systems enhance component quality, reduce operational costs, and ensure long-term performance of forging dies. By choosing Adhvika Forge Tech, you get robust, high-quality, and low-maintenance descaling solutions that integrate seamlessly into your forging lines, helping you achieve better yield, productivity, and profitability.