Electric Screw Press Manufacturer – Future of Forging

Got it. I’ll write 5000 characters of detailed content for the topic:

“Electric Screw Press Manufacturer – Future of Forging”

I will keep it SEO-friendly, professional, and aligned with Adhvika Forge Tech’s branding.

Electric Screw Press Manufacturer – Future of Forging

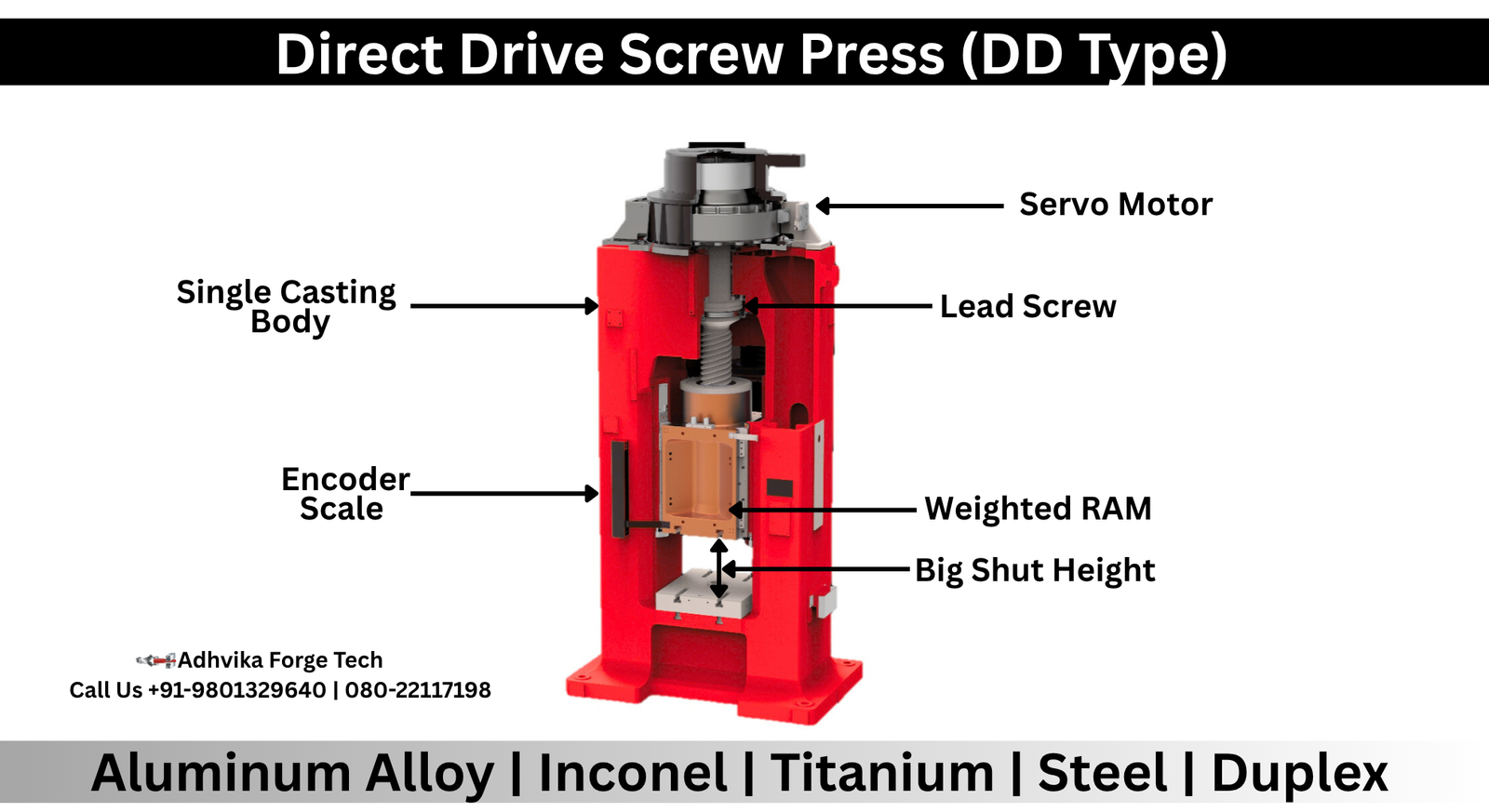

The forging industry is evolving rapidly, with a growing demand for precision, energy efficiency, high productivity, and low maintenance solutions. Among all modern forging technologies, the Electric Screw Press (ESP) has emerged as a game-changer, combining the power of traditional forging presses with the precision of advanced control systems. At Adhvika Forge Tech, we specialize in providing world-class Electric Screw Presses designed to meet the diverse needs of automotive, aerospace, defense, medical, and industrial sectors.

Our Electric Screw Presses deliver high forging accuracy, better material utilization, longer die life, and lower production costs compared to conventional mechanical and hydraulic presses. With servo motor-driven technology and inverter-based controls, the machine ensures smooth operation, reduced noise, minimal vibration, and energy savings of up to 30–40%, making it ideal for forging companies looking to upgrade to the next generation of forging equipment.

Key Advantages of Electric Screw Presses

- Precision Forging:

The press provides high positional accuracy, ensuring uniformity in forged components. This results in superior dimensional tolerances and a high-quality finish. - Energy Efficiency:

Equipped with ABB inverter drives and Siemens PLC control systems, our presses reduce power consumption, lower carbon emissions, and offer better ROI for forging industries. - High Productivity:

With faster cycle times and automation options like forging robots, manipulators, and pick-and-place systems, companies can achieve high-volume production with reduced labor dependency. - Extended Die Life:

Controlled forging strokes minimize sudden shocks on dies, reducing wear and increasing die life by 20–30% compared to traditional presses. - Versatile Applications:

Suitable for aluminum, steel, titanium, and exotic alloys, our presses are widely used in manufacturing automotive control arms, aerospace parts, railway couplers, medical implants, valves, and flanges.

Why Choose Adhvika Forge Tech?

At Adhvika Forge Tech, we are not just manufacturers—we are forging solution partners. Our team offers end-to-end turnkey solutions covering:

- Machine supply & installation with complete foundation drawings

- Tooling and die design using advanced simulation software

- Automation integration with robots and material handling systems

- Operator training & process optimization

- After-sales service with a 3-year warranty and local support

We also provide customized press capacities from 250 tons to 8500 tons based on production requirements. Each press is built with robust engineering design, tested components, and industry 4.0-ready automation systems.

Future of Forging with Electric Screw Presses

The future of forging lies in sustainability, digitalization, and precision engineering. Electric Screw Presses perfectly align with these goals by offering:

- IoT-enabled data monitoring for predictive maintenance

- AI-based forging simulation for process optimization

- Energy-efficient motors and drives for cost reduction

- Automated forging lines for consistent production quality

By adopting Electric Screw Presses, forging companies can achieve higher efficiency, reduced operating costs, better environmental compliance, and global competitiveness.

Applications Across Industries

- Automotive: Control arms, knuckles, gears, shafts, bearings

- Aerospace: Titanium components, structural parts, precision forgings

- Defense: Armored vehicle components, artillery parts

- Railways: Couplers, axles, heavy-duty forged parts

- Medical: Orthopedic implants like hip stems and knee joints

- Industrial: Valves, flanges, oil & gas equipment

Our presses ensure high forging yields (up to 92%), low material wastage, and consistent part quality—a must for these demanding sectors.

Conclusion

As the forging industry moves towards smart manufacturing and green technology, Electric Screw Presses are set to dominate the future. At Adhvika Forge Tech, we combine cutting-edge technology, cost-effective solutions, and unmatched expertise to help forging companies modernize their production lines.

Whether you need a single press or a complete automated forging line, we provide one-window turnkey solutions from concept to commissioning. Partner with us to shape the future of forging with reliable, efficient, and innovative Electric Screw Press technology.