Discover Electric Screw Press solutions by Adhvika Forge Tech. Enhance efficiency, precision, and energy savings for Indian manufacturers. Future-ready forging technology.

Electric Screw Press: Future-Ready Solutions for Indian Manufacturers

Adhvika Forge Tech is proud to offer state-of-the-art Electric Screw Press solutions, revolutionizing the forging industry in India. As the demand for precision, efficiency, and cost-effectiveness increases, our Electric Screw Press machines provide a future-ready solution that caters to the diverse needs of manufacturers across various sectors, including automotive, aerospace, and heavy engineering.

Advanced Technology for Precision Forging

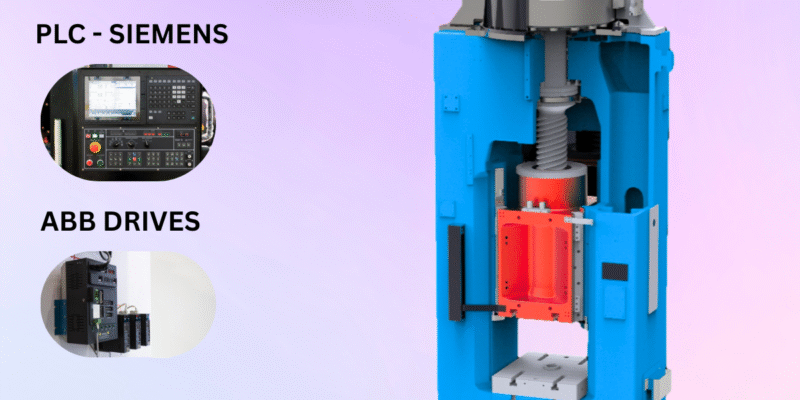

Our Electric Screw Presses are equipped with cutting-edge technology that ensures precision in every strike, resulting in consistent and high-quality forged components. The advanced motor-driven mechanism of our presses ensures greater control over the process, leading to minimized errors and optimized material use. This level of precision is crucial for industries where high tolerance and component integrity are essential, such as aerospace and defense.

Energy Efficiency and Cost Savings

One of the most significant advantages of Adhvika Forge Tech’s Electric Screw Presses is their energy efficiency. Unlike traditional mechanical presses, which rely on flywheels and clutches to store energy, our Electric Screw Presses use electric drives to generate power, resulting in significant energy savings. This technology reduces overall operational costs by lowering energy consumption, which is a critical factor in industries where electricity is a major cost component.

Additionally, these presses have a longer operational lifespan due to fewer moving parts and lower wear and tear, contributing to reduced maintenance costs over time. The energy-efficient nature of these presses also supports sustainability initiatives by minimizing the carbon footprint, which is essential for modern manufacturing companies aiming to align with global environmental standards.

Enhanced Production Capabilities

Electric Screw Presses are designed to increase throughput and reduce cycle time, offering manufacturers the ability to achieve faster production rates without compromising on quality. With the ability to adjust the energy output according to the specific needs of the forging process, these presses allow manufacturers to handle a wide range of materials, from soft metals to harder alloys. This versatility ensures that the presses are suitable for multiple applications, including forging of automotive components, turbine blades, and structural components for construction and infrastructure projects.

Low Maintenance and High Durability

Adhvika Forge Tech’s Electric Screw Presses are designed with durability in mind. The robust structure of the machine ensures that it can withstand the rigors of continuous operation, making it an ideal choice for high-volume manufacturing environments. Furthermore, the press’s advanced control systems offer predictive maintenance alerts, ensuring that any potential issues are identified and addressed before they lead to downtime, further enhancing operational efficiency.

Customizable to Meet Diverse Needs

We understand that every manufacturing process is unique, which is why our Electric Screw Presses are fully customizable to meet the specific needs of our clients. Whether it’s for the forging of complex aerospace components or high-strength automotive parts, our presses can be tailored to provide the exact amount of energy required for each application. Adhvika Forge Tech works closely with clients to design and implement presses that meet their exact specifications, ensuring that each customer receives the best possible solution for their forging needs.

Long-Term Support and Service

At Adhvika Forge Tech, we go beyond just selling machines—we provide comprehensive after-sales support and maintenance services. Our team of experts is always available to assist with installation, training, and ongoing service requirements. With our robust support system, customers can be assured of a smooth operation and minimized disruptions. We offer warranties and long-term service contracts that ensure the longevity and optimal performance of our Electric Screw Presses.

Conclusion

Adhvika Forge Tech’s Electric Screw Press solutions are a game-changer for the Indian manufacturing sector. They offer an energy-efficient, precise, and cost-effective alternative to traditional mechanical presses. With their advanced technology, low maintenance, and customizable features, our Electric Screw Presses are set to become a core component of future-ready forging operations across India. Manufacturers looking to enhance their production capabilities, reduce operational costs, and improve component quality can trust Adhvika Forge Tech for their Electric Screw Press solutions.

Why Choose Adhvika Forge Tech?

Innovative Technology: Our Electric Screw Presses incorporate the latest advancements in forging technology to deliver superior results.

Energy Efficiency: Significantly reduces energy consumption, offering a cost-effective solution for high-volume production.

Customization: Tailored to meet the specific needs of various industries, including automotive, aerospace, and defense.

Sustainability: Supports eco-friendly manufacturing practices by minimizing energy use and reducing carbon emissions.

Comprehensive Support: Full after-sales service, training, and technical assistance to ensure your operations run smoothly.

For Indian forging manufacturers looking for a reliable, future-proof forging solution, Adhvika Forge Tech’s Electric Screw Press is the ultimate choice.

Reach out to us today to learn more about how we can help you improve your forging processes and achieve greater efficiency in your production lines.

Call Us +91-9801329640 / 080-22117198

Email : Info@adhvikaforgetech.com / asamitsingh74@gmail.com