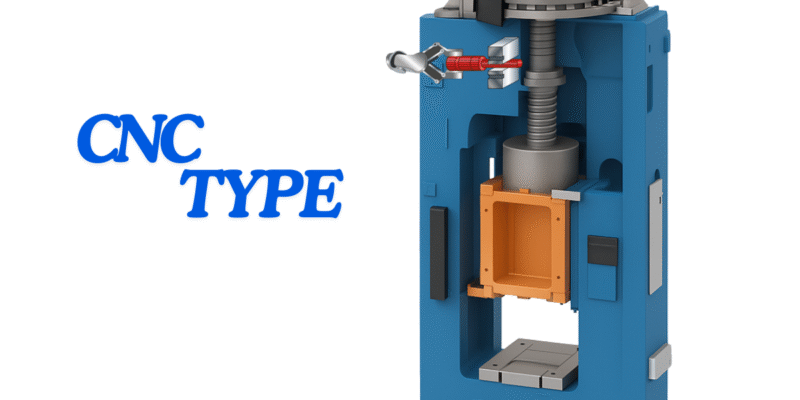

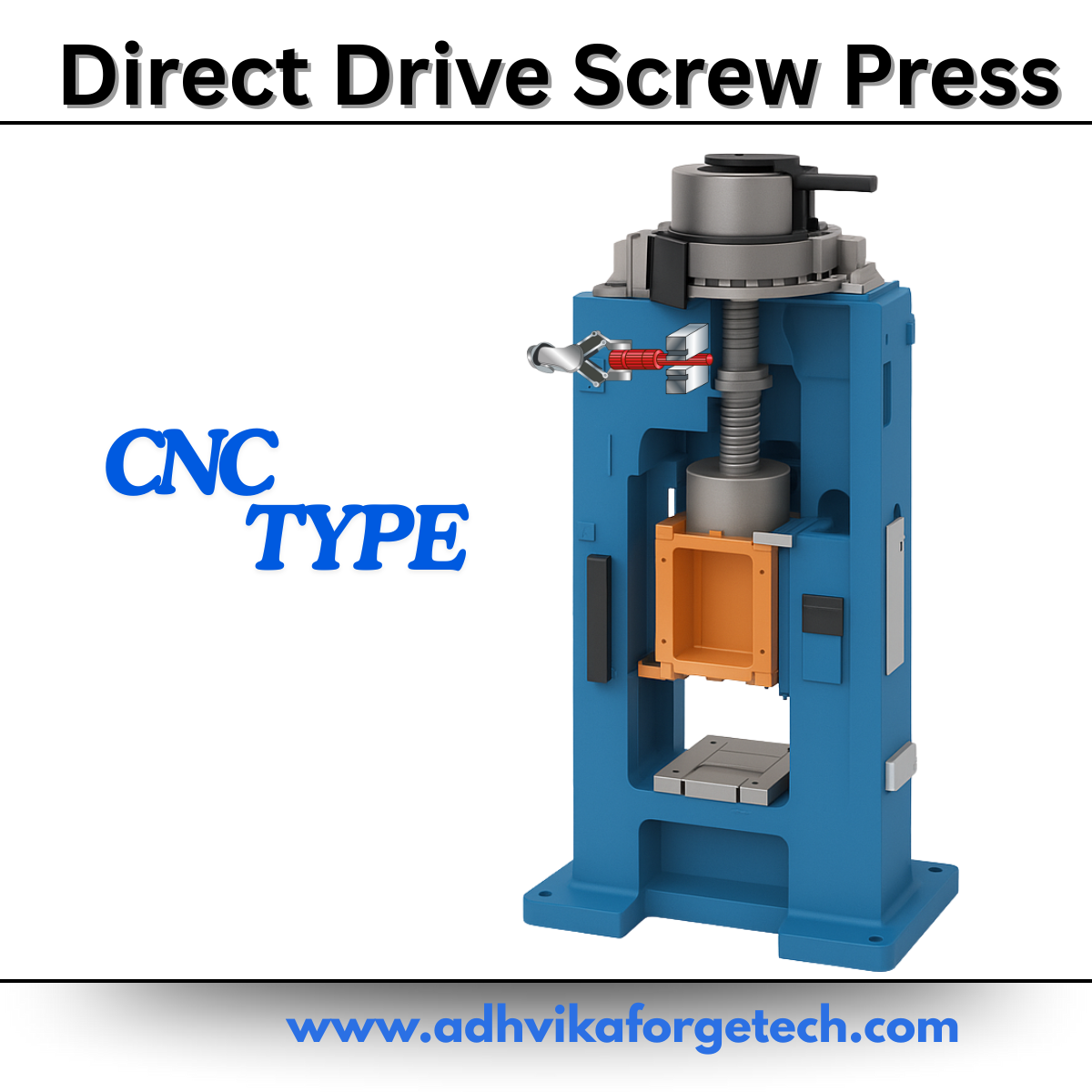

Direct Drive Screw Press delivers high impact and precision, making it perfect for forging a wide range of components like automotive parts, aluminum & titanium alloys, medical implants, defense parts, and railway components. Ideal for mixed forging applications with energy efficiency.

Direct Drive Screw Press – High Impact & Precision Forging Solution

The Direct Drive Screw Press is a modern forging press system designed for high energy efficiency and forging precision. Unlike traditional systems, this press features a single high-torque electric motor directly connected to the screw shaft, which is in turn connected to the RAM/Slider. This direct transmission of power eliminates gearboxes, flywheels, and unnecessary mechanical losses, resulting in a compact yet powerful forging solution.

Key Working Principle:

The motor shaft is directly attached to the screw shaft, which rotates to move the RAM up and down. This configuration ensures minimal power loss, reduced vibrations, and instant torque transfer, enabling the press to deliver a high-impact blow with precise control over stroke and energy.

Key Features:

✅ High Impact Force: Due to direct torque transfer, the system delivers maximum energy with every blow, ensuring deeper penetration and better material flow in complex forgings.

✅ High Accuracy: The direct linkage between motor, screw, and RAM allows tight control over stroke and positioning, ideal for close die, precision, and aerospace forging.

✅ ABB Inverter Drive: The integrated ABB inverter drive system regulates motor speed based on the forging process. It reduces idle energy consumption, enhances safety, and enables energy regeneration during deceleration.

✅ Energy Efficient: Compared to traditional presses, this press consumes up to 30-40% less energy while delivering the same or greater impact energy.

✅ Low Maintenance: Fewer moving parts mean less wear and tear, no clutch or brake mechanisms, and reduced maintenance costs.

✅ Versatile Applications: Best suited for aluminum alloy, titanium, and high-grade steel forgings in automotive, defense, railway, and aerospace sectors.

Why Choose It?

With unmatched force, precision, and sustainability, the Direct Drive Screw Press has become the go-to forging machine for manufacturers seeking fast cycle times, tight tolerance, and energy savings.