Direct Drive Electric Screw Press: Process Analysis & Comparison

Direct Drive Electric Screw Presses are revolutionizing the forging industry with their high efficiency, precision, and energy-saving capabilities. Widely used in automotive, aerospace, and heavy machinery sectors, these presses ensure superior performance with reduced operational costs. In this blog, we will analyze and compare the key aspects of Direct Drive Electric Screw Presses and explore how Adhvika Forge Tech optimizes each step for unmatched forging results.

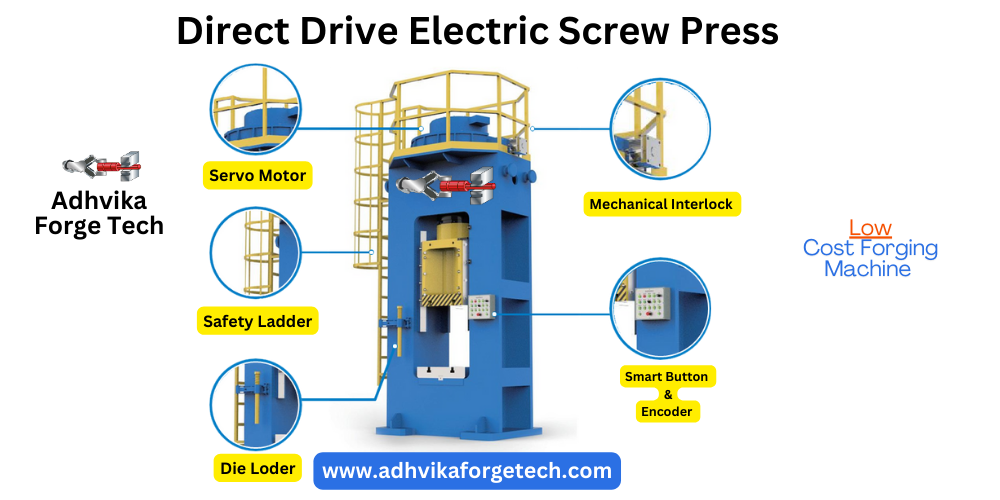

1. Technology Overview

Direct Drive Electric Screw Presses operate with advanced inverter drives, offering precise control over the forging process.

- Key Features: High torque output, energy efficiency, and minimal maintenance.

- Adhvika Forge Tech Advantage: We provide customized Direct Drive Electric Screw Presses integrated with ABB inverter drives and Siemens PLCs, ensuring enhanced performance and durability.

2. Energy Efficiency

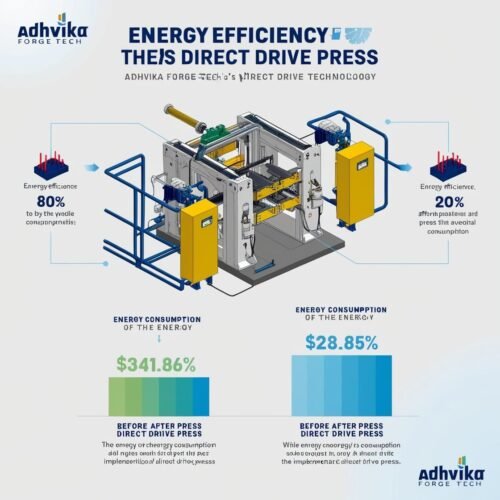

Energy consumption is a critical factor in forging operations.

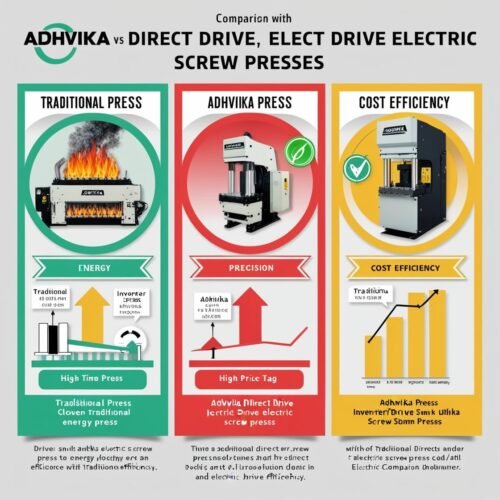

- Traditional Presses: Higher energy consumption due to inefficient mechanical transmission.

- Direct Drive Presses: Improved energy efficiency with direct torque transmission.

- Adhvika’s Contribution: Our presses offer up to 30% energy savings, reducing operational costs significantly.

3. Precision and Control

Precision is key for high-quality forging outputs.

- Traditional Systems: Limited control over stroke and pressure.

- Direct Drive Technology: Precise control of speed, stroke, and force.

- Adhvika’s Role: We implement advanced control systems, ensuring consistent forging quality with minimal defects.

4. Maintenance and Durability

Reducing downtime is crucial for productivity.

- Conventional Presses: Frequent maintenance required for mechanical components.

- Direct Drive Presses: Low maintenance due to fewer moving parts.

- Adhvika’s Support: We provide three years of local service support, ensuring hassle-free operations.

5. Application Versatility

Direct Drive Electric Screw Presses are versatile across various industries.

- Applications: Forging of titanium, aerospace parts, automotive components, and more.

- Adhvika Advantage: We offer turnkey solutions tailored to diverse industrial needs, from aerospace to automotive forging lines.

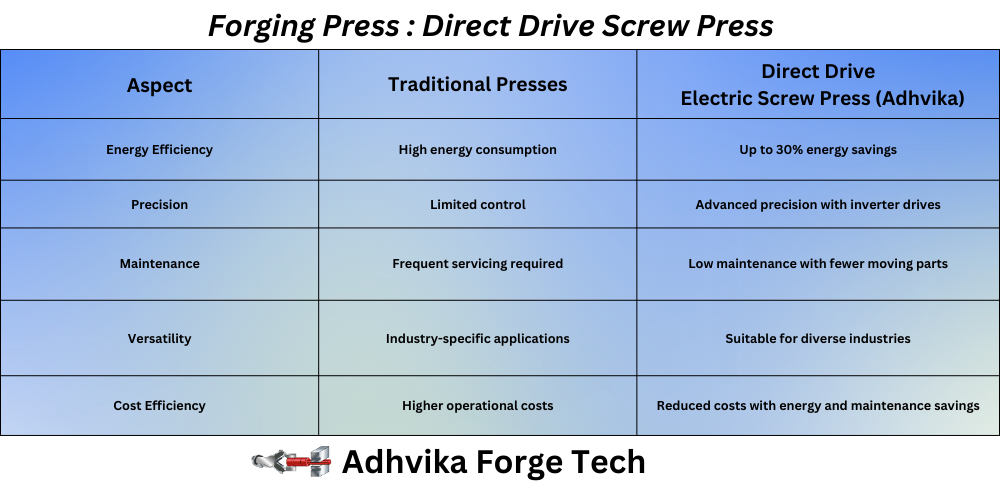

Comparison Summary

Why Choose Adhvika Forge Tech?

- Turnkey Solutions: From installation to commissioning, we manage the complete process.

- Cost Efficiency: Low operational costs with high productivity.

- Global Expertise: Serving clients worldwide with cutting-edge forging technologies.

Conclusion

Optimizing forging operations with Direct Drive Electric Screw Presses ensures higher efficiency, precision, and cost-effectiveness. With Adhvika Forge Tech, manufacturers benefit from advanced technology, energy-saving solutions, and superior product quality.