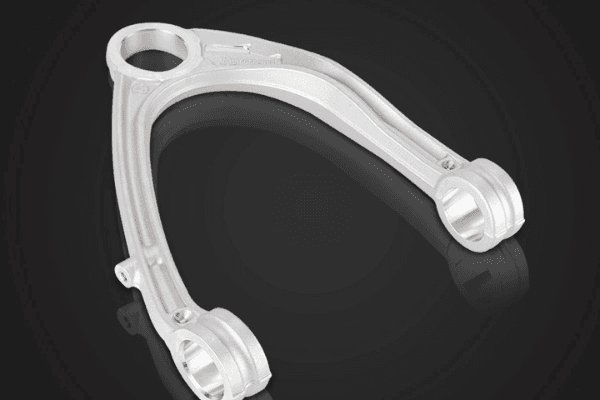

Control Arm Forging Process

Developing a control arm forging process involves several critical steps, and Adhvika Forge Tech can provide comprehensive assistance throughout the entire process. Here’s a step-by-step outline of how they can help:

Here's a step-by-step outline of how they can help:

Material Selection and Procurement:

- Adhvika Forge Tech assists in selecting the appropriate material based on the application requirements of the control arm, such as strength, durability, and weight considerations.

- They facilitate the procurement process, ensuring quality standards are met and cost-efficiency is maintained.

Heat Treatment and Finishing:

- After forging, they manage heat treatment processes to achieve the desired mechanical properties of the control arm.

- Surface finishing and machining services are provided to meet final dimensional and surface quality specifications.

Forging Execution:

- Adhvika Forge Tech employs state-of-the-art forging equipment and processes, including Electric Screw Presses and other advanced machinery.

- They oversee the forging operations to ensure adherence to quality standards and production schedules.

Forging Process Planning:

- Detailed process planning is conducted to determine the forging sequence, temperatures, and pressures required.

- Adhvika Forge Tech utilizes their expertise in forging technology to maximize material utilization and minimize waste.

Tooling Design and Manufacturing:

- Adhvika Forge Tech designs and manufactures custom tooling required for the forging process.

- They ensure that the tooling is precise, durable, and optimized for efficiency in the forging of control arms.

2.Design and Engineering Support:

- Collaborating with clients, Adhvika Forge Tech offers design and engineering expertise to optimize the control arm’s forging process.

- They use advanced software for simulations and modeling to refine designs and ensure manufacturability.

Quality Assurance:

- Throughout the entire process, Adhvika Forge Tech implements rigorous quality control measures.

- They conduct inspections and testing at various stages to verify conformance to customer requirements and industry standards.

Logistics and Support:

- Adhvika Forge Tech manages logistics, including packaging and shipping of finished control arms to customer locations.

- They provide ongoing support for installation, troubleshooting, and maintenance as needed.

Material Selection and Procurement:

- Adhvika Forge Tech assists in selecting the appropriate material based on the application requirements of the control arm, such as strength, durability, and weight considerations.

- They facilitate the procurement process, ensuring quality standards are met and cost-efficiency is maintained.