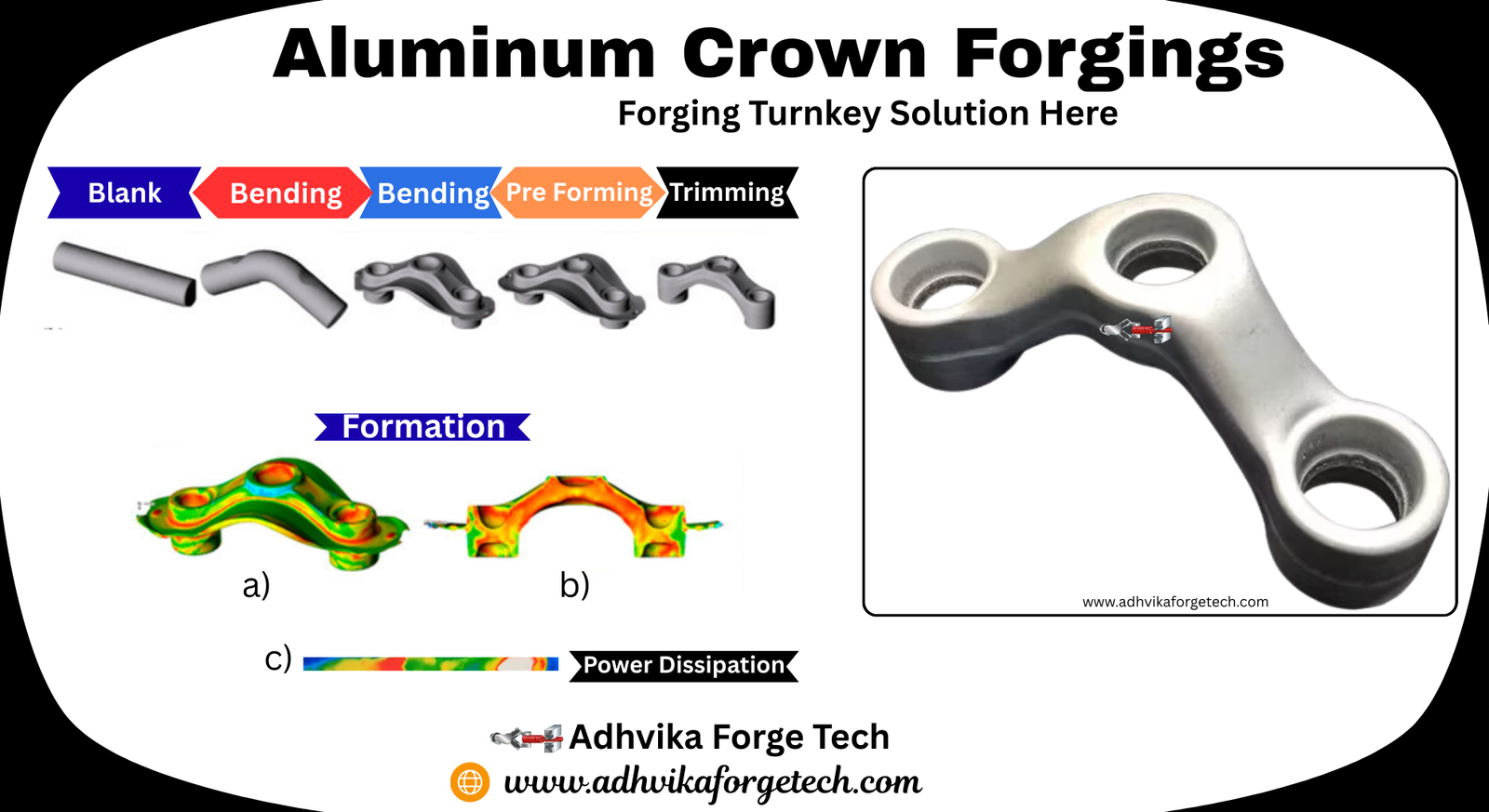

Aluminum Crown Forgings Turnkey Solutions – Lightweight, Durable, and High-Strength Components with Optimized Die Design, Automation & Quality Assurance.

Aluminum Crown Forgings – Turnkey Solutions for Automotive & Industrial Sectors

Aluminum Crown Forging Solution – High Precision & Optimal Performance

Adhvika Forge Tech, we specialize in providing complete turnkey solutions for aluminum crown forgings, serving automotive, shock absorber, and heavy machinery industries. Aluminum crown components play a critical role in suspension systems, shock absorber assemblies, and automotive structural parts, where strength, lightweight design, and durability are paramount. Our solutions ensure precision forging, high productivity, and reduced material wastage through advanced technologies and process optimization.

Our aluminum crown forging solution begins with detailed project analysis. Every project is assessed for material selection, billet dimensions, and die design, ensuring the best combination of mechanical properties, formability, and cost-effectiveness. We work with high-quality aluminum alloys, optimized for strength-to-weight ratio, corrosion resistance, and thermal stability, making them ideal for automotive and industrial applications.

Advanced Die Design and Simulation:

We employ CAD modeling and Finite Element Method (FEM) simulation to design forging dies that ensure uniform material flow, minimal defects, and optimal grain structure. Our die designs include controlled deformation zones (CDZ), which allow for precise shaping while maintaining mechanical integrity of the aluminum crowns. This approach significantly reduces the chances of surface cracking, folding, or internal voids, which are common in complex aluminum forging operations.

Optimized Forging Process:

We implement process optimization techniques such as Response Surface Method (RSM), Main Effects Plot (MEP), and Taguchi combined with Grey Relational Analysis (GRA) to determine the ideal billet diameter, length, and barrier wall design. This ensures consistent dimensional accuracy, high yield, and reduced scrap rates. Our process control allows tight tolerances, making the components ready for assembly without additional machining, saving both time and cost.

Modern Forging Equipment:

Our aluminum crown forgings are produced using Electric Screw Presses, Hydraulic Presses, and CNC Hammers, which provide precise force control and repeatable operations. These machines ensure high production rates, energy efficiency, and extended die life, essential for large-scale production. We also provide semi-automatic and fully automatic lines with manipulators and robots for billet handling, reducing cycle time and labor costs, while improving safety standards in the plant.

Heat Treatment and Surface Finishing:

Post-forging, aluminum crowns undergo controlled heat treatment to achieve the desired hardness, strength, and toughness. Our expertise in solution treatment, aging, and annealing processes ensures components meet stringent mechanical and metallurgical standards. Surface finishing operations such as deburring, shot blasting, and anodizing are applied as per client requirements, providing a high-quality finish and long-lasting performance.

Quality Assurance and Testing:

Quality is central to our operations. Each aluminum crown forging undergoes rigorous inspection, including dimensional checks, hardness tests, and non-destructive testing (NDT) to ensure compliance with automotive and industrial standards. Our ISO-compliant processes ensure zero compromise on safety, performance, and reliability.

Sustainability and Material Efficiency:

We focus on energy and material efficiency through optimized billet usage, minimized scrap, and reduced power consumption. Our advanced forging lines and automated systems ensure eco-friendly production while maintaining high output.

Why Choose Adhvika Forge Tech for Aluminum Crown Forgings:

End-to-end turnkey solution from design to finished component

Expertise in high-precision aluminum alloy forging

Automation & robotic handling for safety and efficiency

Optimized die and process design for superior formability

Global experience in automotive, shock absorber, and heavy machinery components

Quality assurance through rigorous testing and inspection

By leveraging advanced technology, process optimization, and industry expertise, Adhvika Forge Tech delivers aluminum crown forgings that are lightweight, durable, and highly precise, enabling better vehicle performance, reduced energy consumption, and longer service life. Whether it’s for automotive OEMs, heavy machinery manufacturers, or industrial applications, our customized solutions ensure your components meet exact specifications while maintaining cost-effectiveness and production efficiency.

Adhvika Forge Tech – www.adhvikaforgetech.com

Call Us +91-9801329640 | 080-22117198

#AluminumForging #CrownForging #AutomotiveComponents #AdhvikaForgeTech #PrecisionForging #ForgingSolutions #LightweightComponents #DieDesign #ForgingAutomation #HighPerformanceMaterials