Adhvika Forge Tech – Leading forging press manufacturer, delivering precision machines, turnkey solutions & global service for close die & open die forging.

Adhvika Forge Tech – Leading Forging Press Manufacturer & Turnkey Solution Provider ⚙️🔥

At Adhvika Forge Tech Pvt. Ltd., we are more than just a forging press manufacturer — we are a complete solution partner for the forging industry. With decades of combined industry expertise, we deliver precision engineering, advanced technology, and cost-effective manufacturing solutions to customers worldwide.

We specialize in designing, manufacturing, supplying, and commissioning forging presses for Close Die Forging, Open Die Forging, Cold Forging, and Warm Forging applications across automotive, aerospace, railways, medical, oil & gas, and heavy engineering sectors.

1️⃣ Our Forging Press Range

We manufacture and supply a complete range of forging presses, tailored to different industrial needs:

Electric Screw Presses – From 250 Ton to 8500 Ton, with ABB inverter drive and Siemens PLC.

Direct Drive Screw Presses – High precision, energy-efficient, low maintenance.

Hydraulic Forging Presses – For precision forming of complex shapes.

Mechanical Forging Presses – High-speed production with robust build quality.

CNC Screw Presses – Automated, programmable forging for maximum repeatability.

Pneumatic & Drop Hammers – For open die applications and heavy forging.

2️⃣ Why Choose Adhvika Forge Tech Presses

Our forging presses stand out for their:

Precision & Repeatability – Ensuring consistent forging quality.

Energy Efficiency – Inverter drive systems reduce power consumption by up to 30%.

Robust Build Quality – Long service life with minimal downtime.

Multi-Material Capability – Steel, aluminium, titanium, copper, and more.

Automation Ready – Easy integration with robotic handling systems.

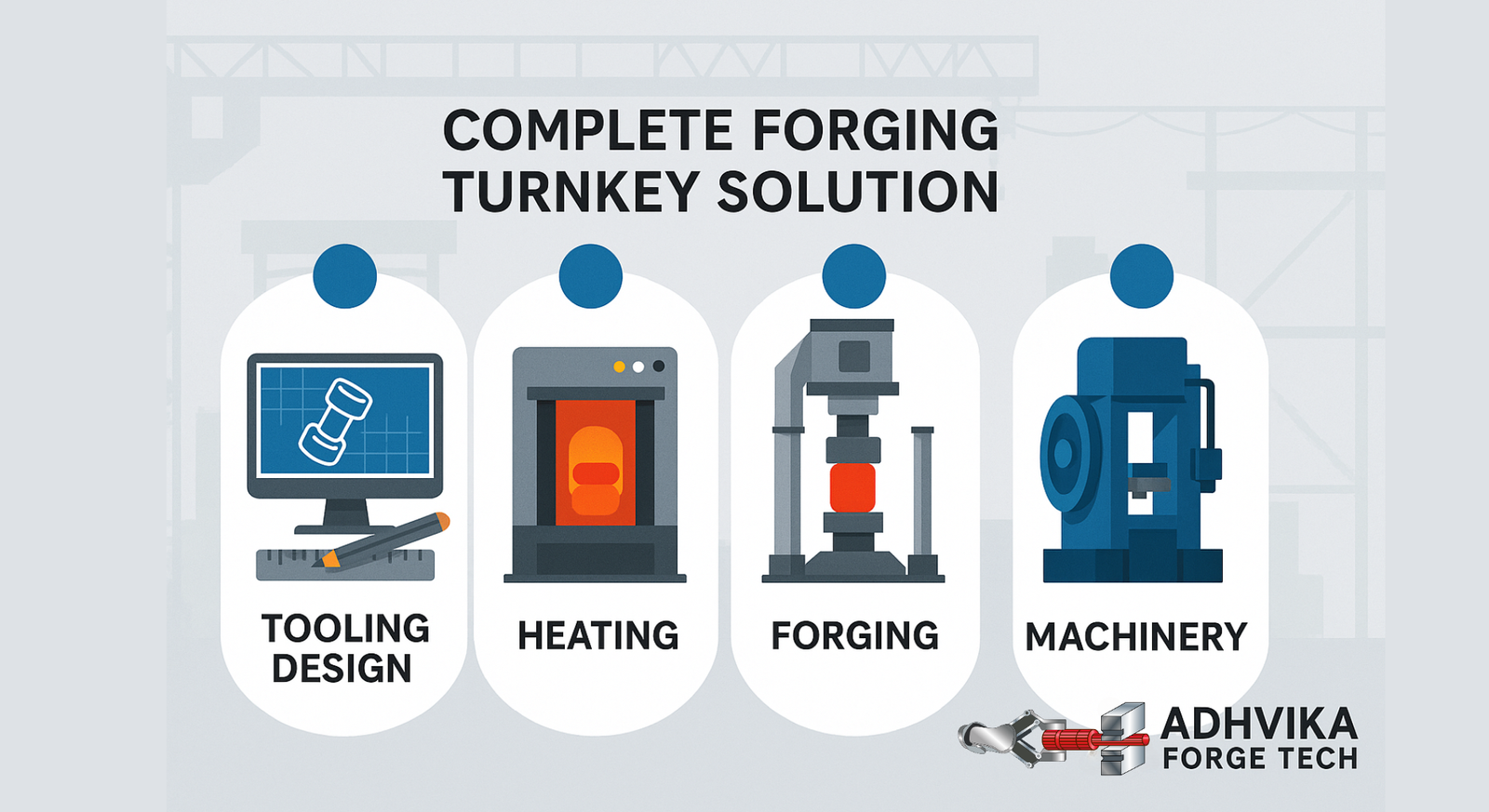

3️⃣ Turnkey Forging Solutions

As a forging press manufacturer, we also provide complete plant setup services:

Tooling & Die Design – Using 3D simulation for material flow and yield improvement.

Heating Systems – Induction and gas-fired furnaces for billet heating.

Forging Lines – Complete automation with conveyors, manipulators, and robots.

Quality Control Systems – Precision measuring tools and testing equipment.

Training & Process Optimization – Ensuring your team runs the plant at peak performance.

4️⃣ Manufacturing Excellence

Our forging presses are built in state-of-the-art facilities with:

CNC machining for high-precision components.

Heavy-duty frame construction for vibration resistance.

Strict quality control at every stage of production.

Trial forging runs before dispatch to guarantee performance.

5️⃣ Global Installation & Service

We serve clients in India and across the globe with:

On-site installation & commissioning.

Foundation & civil work guidance.

Operator training & skill development.

Local service support for quick breakdown response.

Ready spare parts availability.

6️⃣ Industries We Serve

Our forging presses are used in:

Automotive – Crankshafts, control arms, gears, shafts, bolts.

Aerospace – Titanium and aluminium alloy precision components.

Railways – Couplers, axles, and track components.

Oil & Gas – Flanges, valves, and fittings.

Medical – Orthopedic implants and surgical tools.

Our Commitment

When you choose Adhvika Forge Tech, you get:

✅ Best-in-class machines at competitive prices.

✅ Customized solutions for your production needs.

✅ End-to-end project management from concept to commissioning.

✅ Long-term partnership with strong after-sales support.

#AdhvikaForgeTech #ForgingPress #ForgingSolutions #ElectricScrewPress #ForgingMachines #CloseDieForging #OpenDieForging #ForgingIndustry #TurnkeySolutions #HydraulicPress #MechanicalPress #ForgingConsultant #IndustrialMachinery #EnergySavingPress #GlobalForging #HeavyMachinery #ForgingProjects