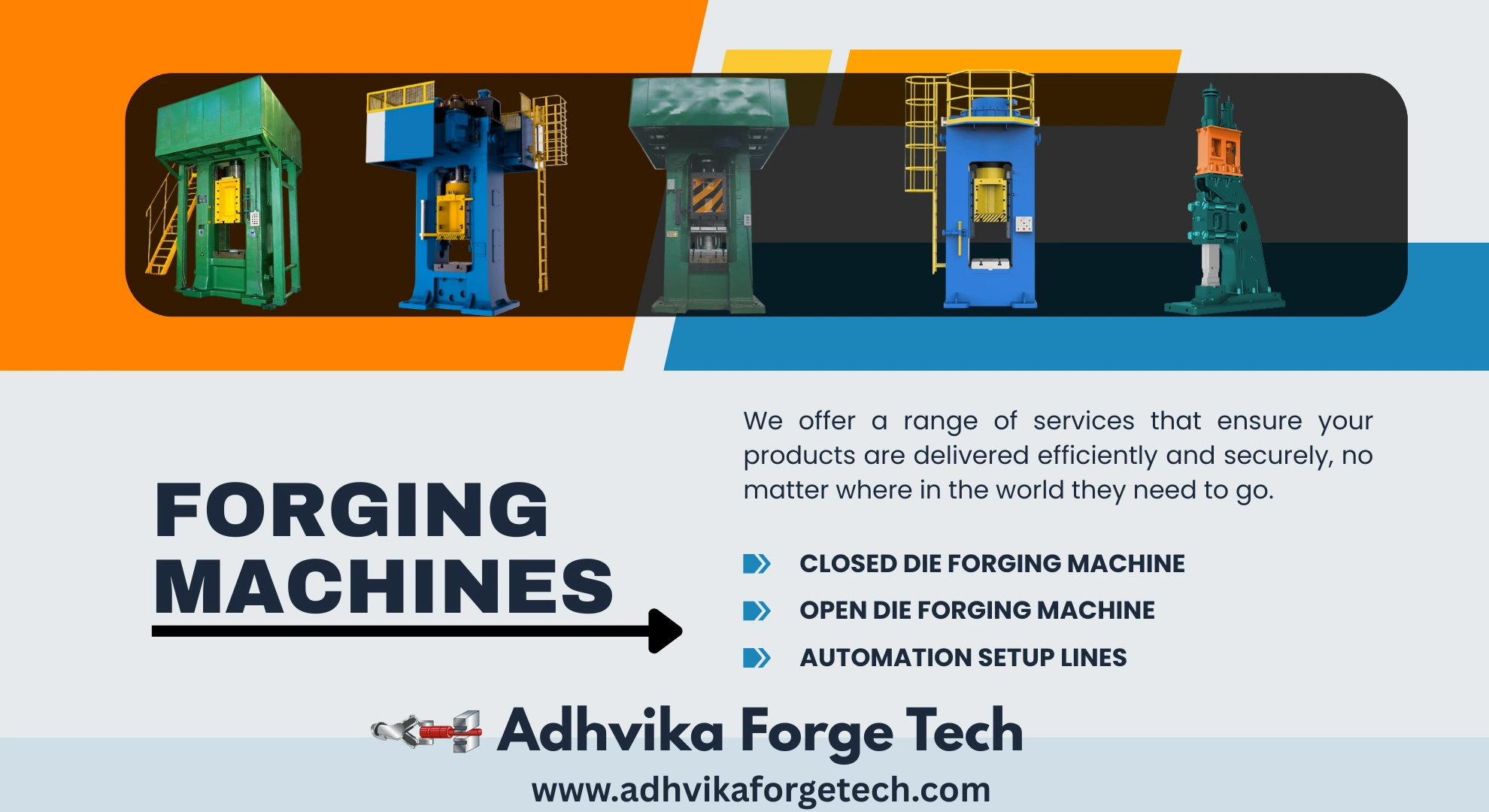

Adhvika Forge Tech - All Type Closed Die & Open Die Press Manufacturer

Adhvika Forge Tech is built on a simple belief — modern forging shouldn’t just be about buying machines, it should be about building reliable, efficient, and future-ready manufacturing systems. We work closely with our customers to provide complete solutions in both Closed Die and Open Die Forging, along with automation, robotic handling, and integrated manufacturing support. Instead of acting like a vendor, we prefer to work as a technical partner who understands real-world challenges on the shop floor.

Our customers to provide complete solutions in both Closed Die and Open Die Forging, along with automation, robotic handling, and integrated manufacturing support. Instead of acting like a vendor, we prefer to work as a technical partner who understands real-world challenges on the shop floor.

Our team has hands-on experience across automotive, aerospace, defence, oil & gas, railways, heavy engineering, and industrial components. Whether it is a new project setup or upgrading an existing line, we help customers make the right technical and investment decisions. From process design, layout planning, machine selection, tooling and dies, installation, commissioning, and production support, we stay involved at every stage to ensure stable and productive operations.

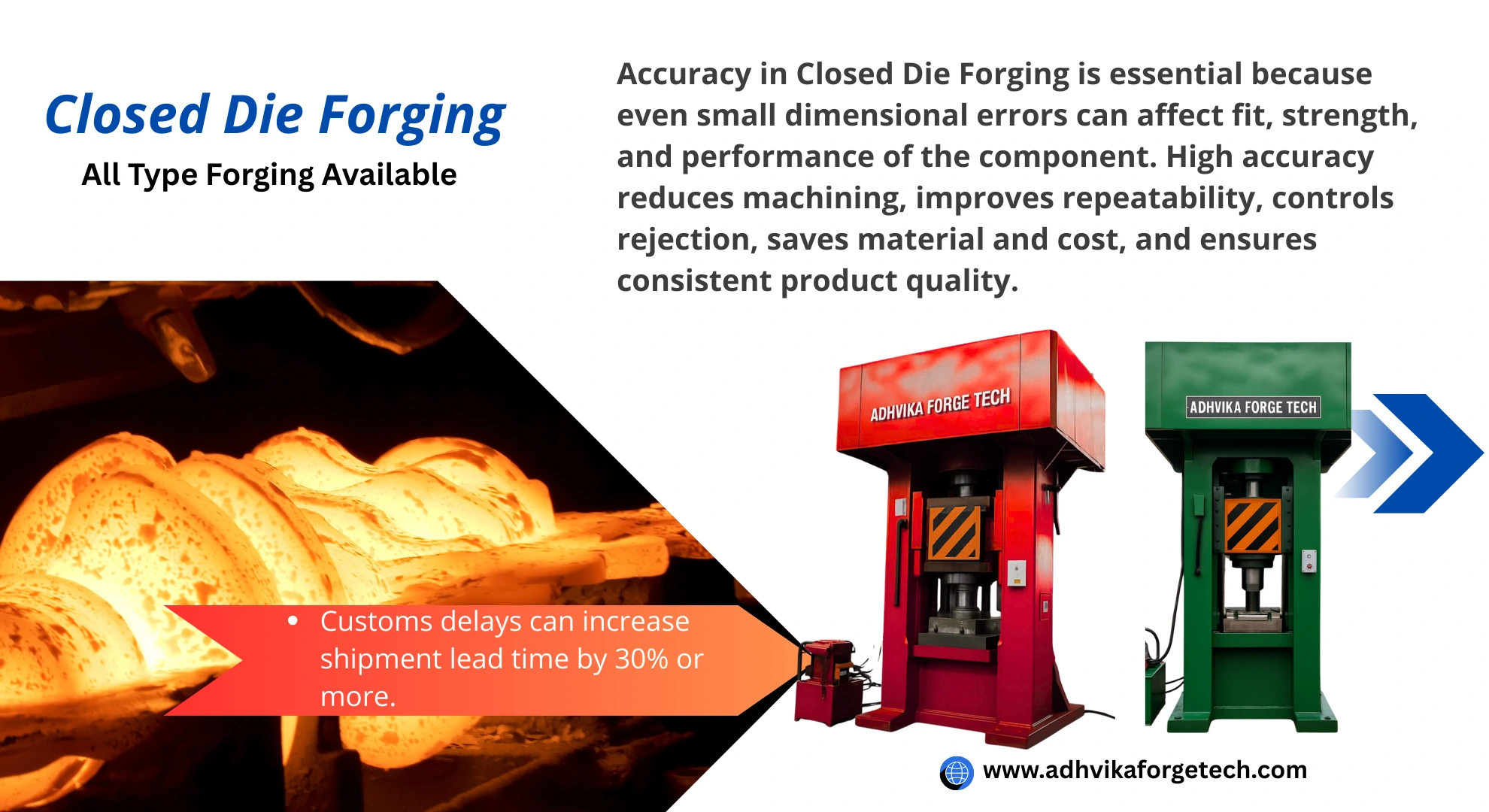

In Closed Die Forging, we support precision and near-net-shape components, focusing on quality, material flow, and rejection control. In Open Die Forging, we work on shafts, rings, flanges, and large industrial parts with practical handling solutions and efficient workflows. Our automation capability — including robots, manipulators, billet transfer and PLC/SCADA systems — helps improve safety, consistency, and productivity while reducing manual dependence.

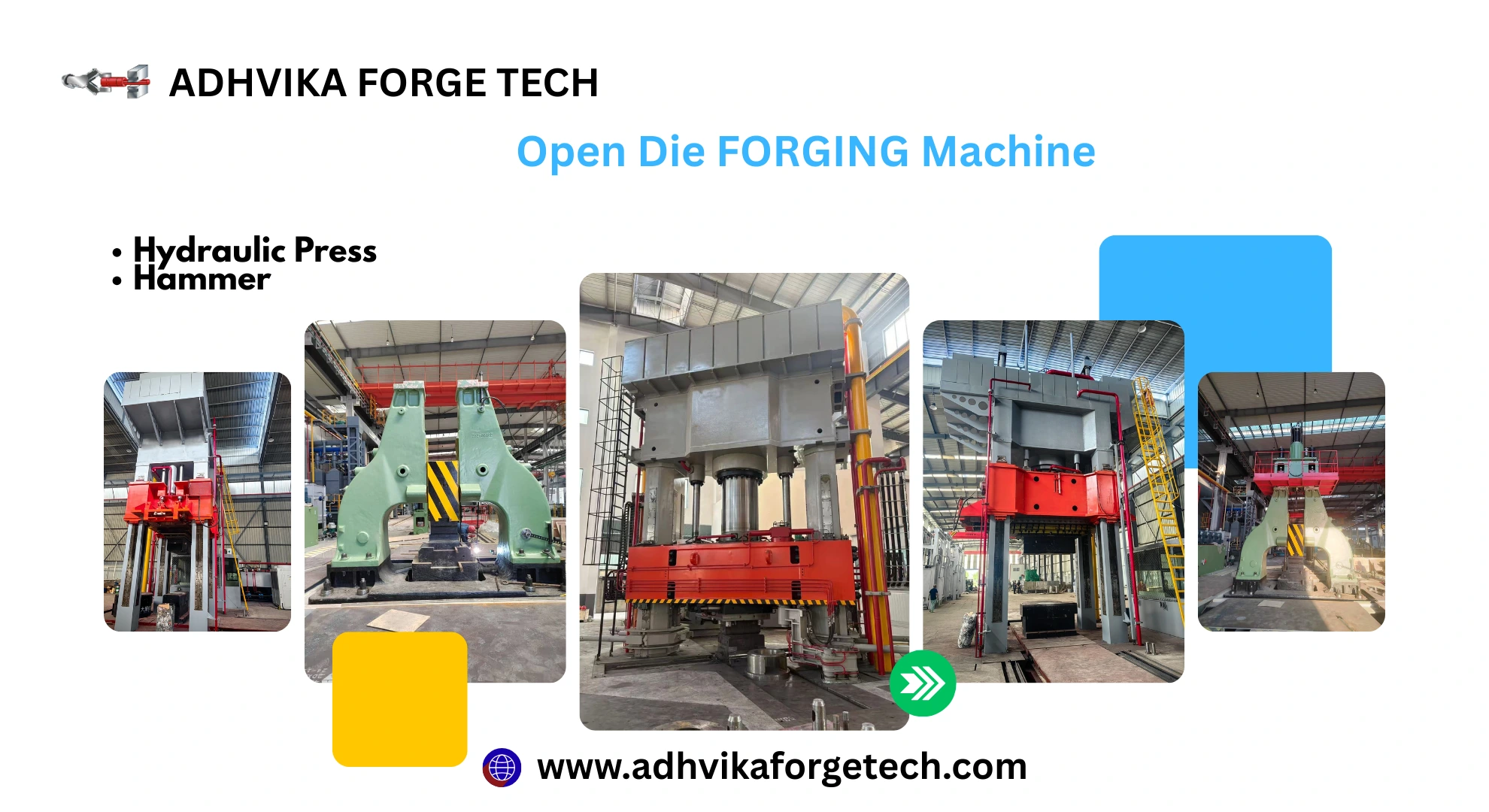

Open Die Forging requires strength, reliability, and flexibility — and that’s exactly what we deliver through our Hydraulic Press Four-Column lines, C-Frame Hammers, and Double-Column Hammers. Adhvika Forge Tech supplies these machines along with complete turnkey solutions, including layout planning, handling systems, installation, commissioning, and production support. Our focus is on practical performance — stable forging blows, smooth material flow, and long service life of equipment. Whether the requirement is shafts, flanges, rings, or heavy industrial components, we provide the right machine configuration based on application needs, energy efficiency, and cost optimization. With our engineering support and on-site guidance, customers get a dependable and production-ready open die forging setup.

Beyond new machines, we also support customers with retrofit upgrades, overhauling, maintenance support, consumables, spare parts, and training, so that their plants remain reliable and sustainable over the long term. Every solution we provide is designed to be cost-effective, customizable, and production-oriented, keeping the future growth of the customer in mind.