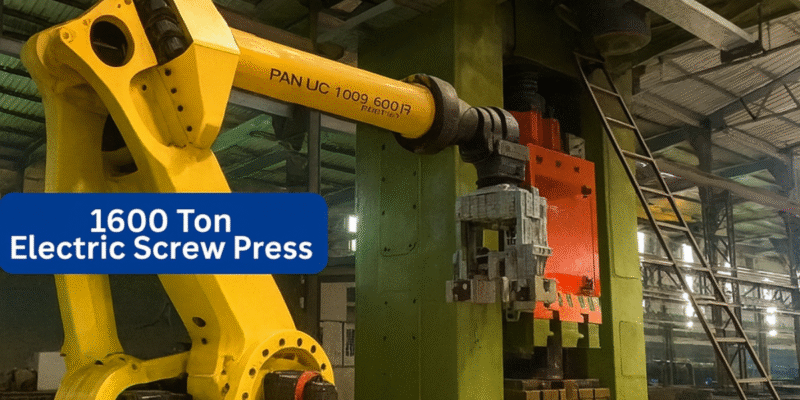

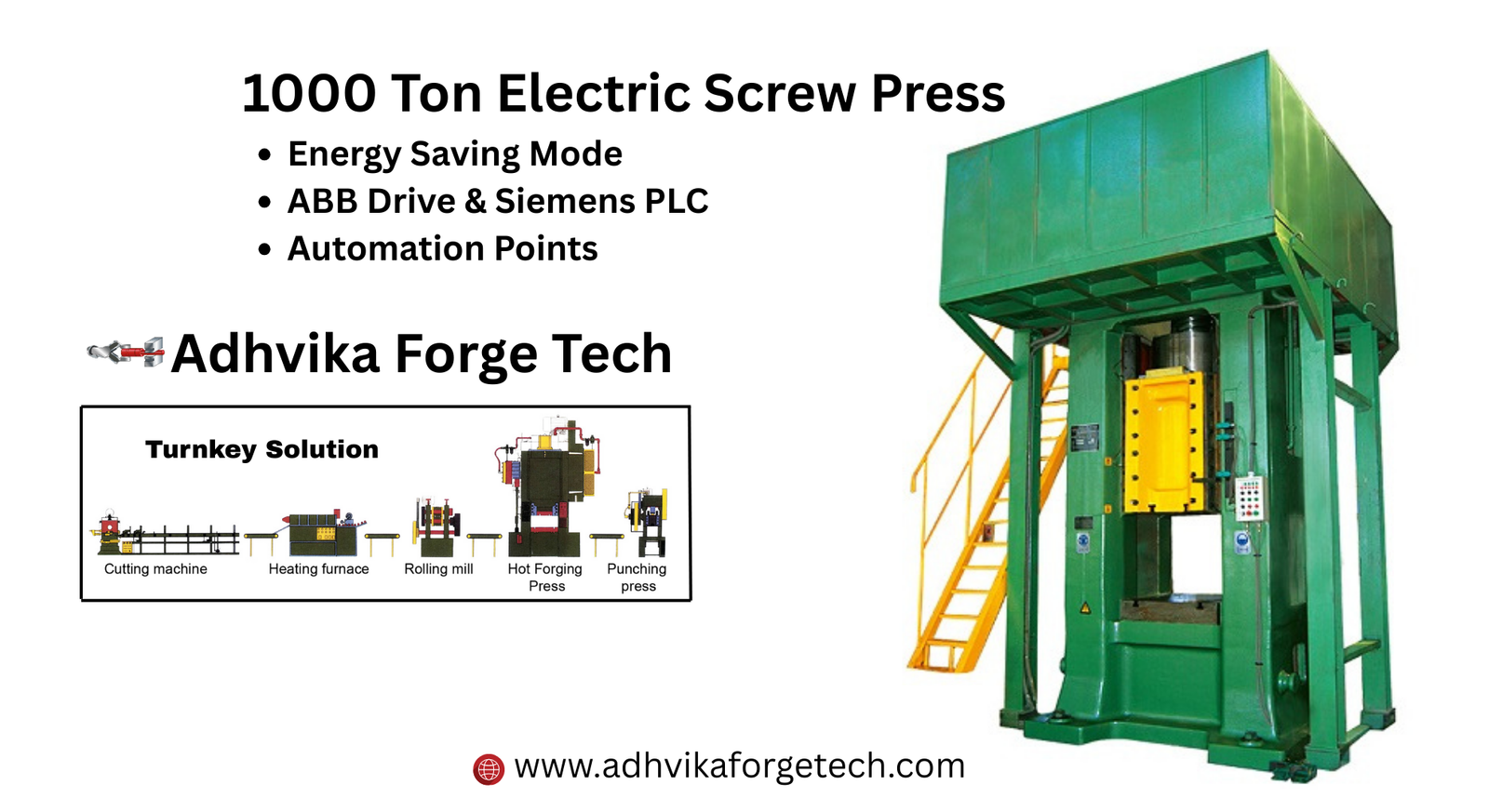

EP Electric Screw Press – Low Maintenance, High Accuracy Forging Solution

Electric screw press combines precision, efficiency, and safety for advanced forging and forming applications, featuring energy-saving, fully automatic operation and multiple safety systems for stable, low-maintenance production

An electric screw press is a precision forging machine that uses an electrically-driven screw mechanism to generate pressing force, delivering advantages such as accurate energy control, strong anti-tilting capacity, and reliable, low-maintenance operation.

Advantages Of EP Electric Screw Press

Simple and Technically Clear list of advantages of an Electric Screw Press

- Precision Forging: Accurate control of forging energy ensures consistent product quality.

- Energy Efficiency: Power is consumed only during forging stroke, reducing electricity costs.

- Strong Anti-Tilting Capacity: Balanced load design minimizes side thrust and improves press life.

- Low Maintenance: Fewer mechanical components mean reduced wear and maintenance needs.

- High Reliability: Stable operation with minimal breakdowns for continuous production.

- Versatile Applications: Suitable for precision forging, calibration, and sizing operations.

- Programmable Control: Easy integration with PLC systems for automation and process monitoring.

- Reduced Noise & Vibration: Quiet operation compared to mechanical and hydraulic presses.

- High Productivity: Faster cycle times increase output with less downtime.

- Long Tool Life: Controlled impact energy minimizes die wear and extends tooling life.