Direct Drive Electric Screw Press – Energy saving, high precision & low maintenance forging solution by Adhvika Forge Tech. Future of modern forging.

Direct Drive Electric Screw Press – The Future of Precision Forging

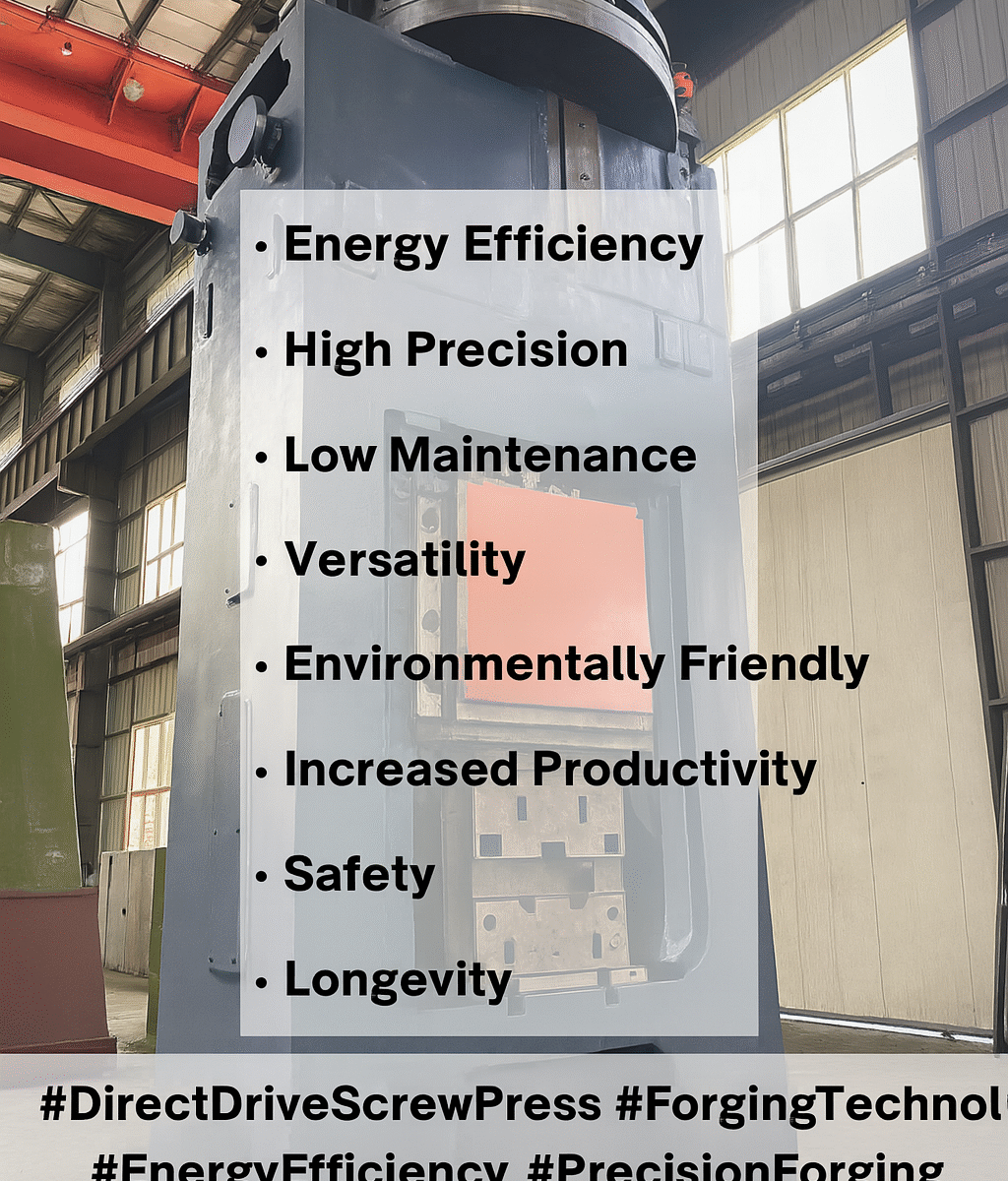

The forging industry is undergoing a major transformation, driven by the demand for energy efficiency, high precision, and reduced downtime. Among the many advancements, the Direct Drive Electric Screw Press (DD-ESP) has emerged as a game-changer in modern forging technology. Unlike traditional mechanical and friction screw presses, which rely on belts, gears, and flywheels, the direct drive system uses an electric servo motor with an inverter drive directly connected to the screw. This innovation eliminates unnecessary energy losses, enhances control, and drastically reduces maintenance costs.

🔋 Energy Saving – Efficient Power Utilization

One of the biggest challenges in forging is high energy consumption, especially in traditional presses that waste significant power in idle running and friction.

In a Direct Drive Electric Screw Press, power is used only when the machine is forging.

The inverter-controlled motor ensures energy is delivered precisely to the stroke required, avoiding wastage.

Studies show 20–40% energy savings compared to friction and gear-driven presses.

With rising electricity costs, this efficiency translates into lower operating costs and faster ROI for forging companies.

🎯 Precision & Accuracy – Controlled Forging at Its Best

In industries such as automotive, aerospace, and defense, precision is critical. Traditional presses often deliver uneven strokes due to mechanical wear or uncontrolled impact. Direct drive technology solves this problem:

Full control of stroke depth and speed through servo and PLC systems.

Consistent forging accuracy, reducing rejections and improving die life.

Capability to perform multi-stroke forging in one die cavity with perfect repeatability.

Force monitoring and programmable settings ensure uniform product quality, whether forging steel, aluminum, or titanium alloys.

🔧 Reduced Maintenance – Simple, Reliable & Durable

Conventional friction screw presses use belts, clutches, and complex gear systems that demand constant monitoring, lubrication, and replacement. Downtime due to wear and tear directly impacts productivity.

The Direct Drive Electric Screw Press eliminates many of these problems:

No friction belts or gears → less mechanical wear.

Fewer moving parts → lower maintenance costs.

Longer motor and screw life due to inverter drive protection from voltage spikes and overloads.

Remote diagnostics and easy service reduce unplanned stoppages.

This makes the direct drive press especially suitable for 24/7 production lines where reliability is non-negotiable.

🌍 Applications Across Industries

🚗 Automotive: Crankshafts, gears, shafts, knuckles, bearings.

🛰️ Aerospace: Titanium components, turbine blades, precision structural parts.

🛡️ Defense: Missile parts, shell casings, heavy-duty components.

🏗️ Industrial & Construction: Flanges, valves, and forged tools.

🌟 Why Direct Drive is the Future of Forging

The forging industry today demands sustainability, precision, and productivity. The Direct Drive Electric Screw Press addresses all three challenges by combining energy efficiency, advanced control, and minimal maintenance. Companies adopting this technology not only save costs but also position themselves as future-ready forging leaders.

At Adhvika Forge Tech, we provide Direct Drive Electric Screw Presses ranging from 250 tons to 8500 tons, with ABB inverters, Siemens PLCs, and local service support. Our expertise ensures that forging companies achieve higher productivity, reduced energy bills, and long-term reliability.

👉 Truly, the Direct Drive Electric Screw Press is not just an upgrade — it is the future of precision forging.

#DirectDriveScrewPress #ElectricScrewPress #ForgingSolutions #AdhvikaForgeTech #EnergyEfficientForging #ForgingAutomation #PrecisionForging #ForgingIndustry #TurnkeySolutions #ForgingConsultant