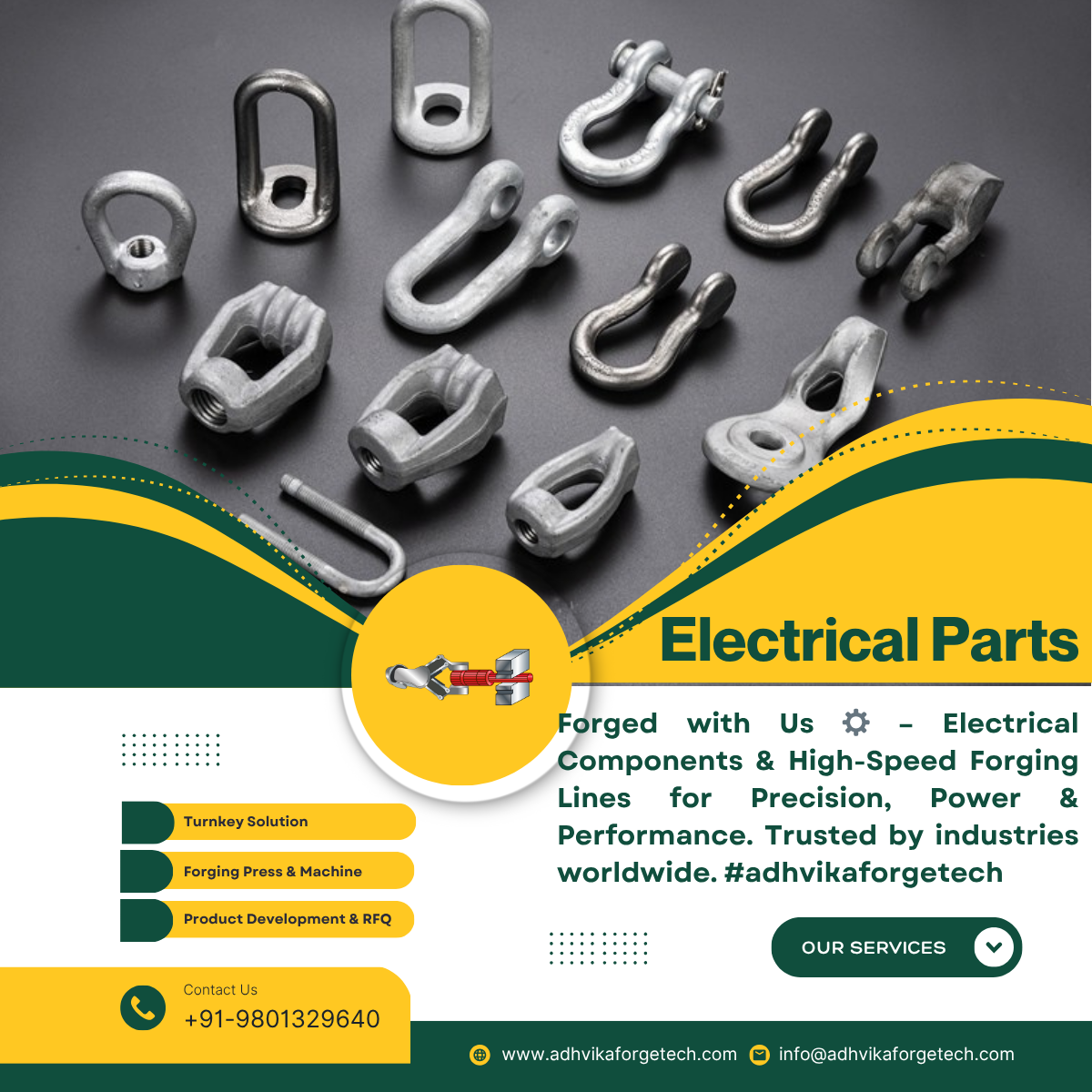

Adhvika Forge Tech provides forging solutions for Electric Power Shackles, Turnbuckles, and Studs used in high-tension power transmission. Trusted for strength, durability, and precision.

Electric Power : Electric power, Bolts,Eye nuts,Shackle,Stud,Turnbuckle

How Adhvika Forge Tech Helps in Forging Solutions for Electric Power Parts and Component Development

Adhvika Forge Tech is a renowned name in the forging industry, offering turnkey solutions and advanced forging technologies across multiple sectors—including the Electric Power Transmission and Distribution industry. In the ever-demanding field of electrical infrastructure, components such as shackles, turnbuckles, clevises, studs, insulator fittings, and connectors must withstand high tensile loads, extreme weather, and corrosion. Adhvika Forge Tech delivers robust forging solutions that meet these stringent requirements through innovation, engineering, and precision manufacturing.

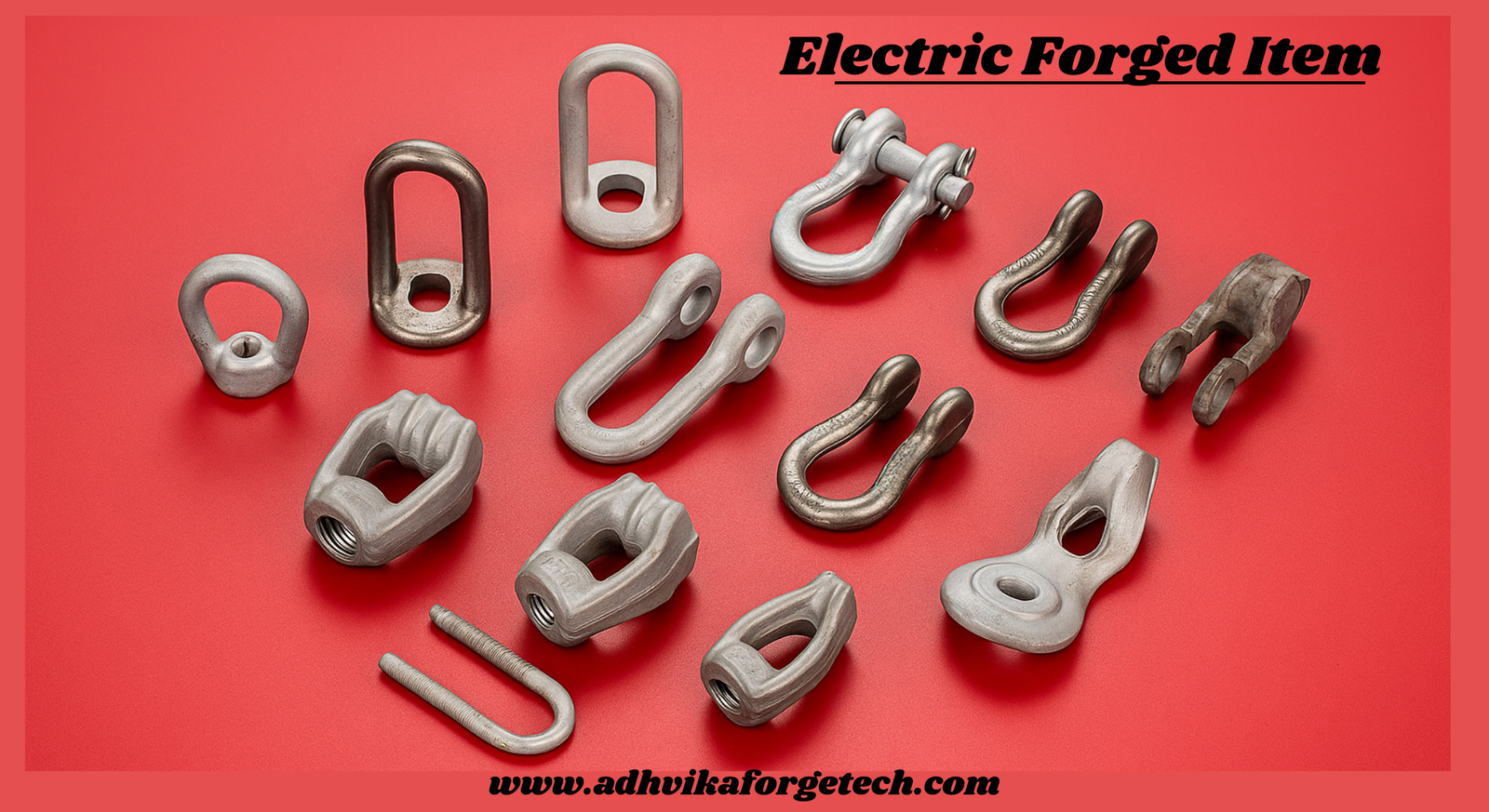

🔩 Key Electric Power Forging Components We Support

Shackles (Anchor & Chain Type)

Turnbuckles & Eye Bolts

Studs & Clamps

Clevis, Socket Clevis, Ball Clevis

Y-Clevis, Socket Tongue, Insulator Hardware

Suspension Fittings and Dead-End Fittings

Earthing & Grounding Rods

High-Tension Transmission Line Fittings

🛠️ Our Role in Forging These Critical Components

1. Product Design & Prototyping

Adhvika Forge Tech begins with design consultation tailored to mechanical load conditions, standard specifications (IS/ANSI/IEC), and end-use applications.

3D modeling of parts using CAD/CAM

Die design for precision and repeatability

Prototype forging for testing mechanical properties

2. Die Manufacturing In-House

We manufacture high-quality closed die blocks and forging bolsters in our in-house tool room. This ensures:

Short lead times

Accuracy in repeated batches

Optimized material flow during forging

3. Selection of Appropriate Forging Equipment

Depending on the size and complexity of the part, Adhvika Forge Tech recommends and supplies the best-suited machines:

Electric Screw Presses (250 to 6300 Tons) – Precision hot forging for clevises, shackles, etc.

Hydraulic Presses – Ideal for socket fittings and connectors

CNC Hammers & Air Hammers – For bulk production and customized requirements

Trimming & Coining Presses – For flash removal and final finishing

4. Material Selection & Optimization

We assist customers in selecting suitable grades such as:

EN8, EN19, SS 304/316, ASTM A105, AISI 4140

Galvanized or Hot Dip Coated Steels

Withstand tensile loads up to 120 kN and above

We ensure optimized material utilization to reduce cost and wastage.

5. Forging Line Setup – Turnkey Projects

We establish complete forging lines on a turnkey basis:

Press + Heating Furnace + Handling Automation + Dies

Complete layout design & utility planning

Production line automation using 6-axis robots

Graphite lubrication & handling arms for hot jobs

Energy-efficient furnace and heating solutions

🔄 Integration with Quality and Testing

Electric power fittings are safety-critical parts. Adhvika Forge Tech ensures:

100% dimensional inspection

Destructive & non-destructive testing (UT, MPI, Load test)

Tensile and yield strength compliance with IEC/ASTM

Coating and galvanization-ready surface finishes

⚙️ Why Forging is Better for Electric Power Parts?

High Strength-to-Weight Ratio

Forged parts have grain flow aligned with the part design, offering better strength than cast or fabricated alternatives.Reliability Under Load

Forged clevis and turnbuckles don’t fail under tension, making them ideal for high-voltage transmission towers.Weather and Vibration Resistance

Electric power components face outdoor environments—our forgings offer better fatigue and corrosion resistance.Zero Porosity

Unlike castings, forged parts are free of internal voids—ensuring safe performance for insulator hardware and tension connectors.

🌎 Industries & Clients We Serve

Power Transmission Line Hardware Manufacturers

EPC Companies in Power Infrastructure

Government Utilities & PSUs

Tower Manufacturers & Insulator Companies

OEM Suppliers for HV & UHV Lines

🔧 End-to-End Services Offered by Adhvika Forge Tech

| Service | Description |

|---|---|

| Consulting | Concept to commissioning support for forging line |

| Machine Manufacturing | Electric Screw Press, Trimming Press, Hammer, Hydraulic Press |

| Die Design | Impression dies, bolster manufacturing |

| Automation Integration | Handling automation, 6-axis robots, conveyors |

| On-Site Installation | Foundation layout, machine erection, commissioning |

| After-Sales Support | 3+ years service, AMC, spares availability |

🏭 Infrastructure & Capabilities

Factory Area: 1 Acre with 20,000 sq. ft shed

Tool Room: CNC and EDM setup for die development

R&D Centre: For trend analysis, electric part load testing

Stock of Ready Presses: For immediate dispatch

Pan India Service Network

📈 ROI and Customer Benefits

30–40% Cost Saving compared to conventional setups

Short Delivery Cycles

Low Maintenance Modern Machines

Quality Compliance as per Power Sector Standards

Support for Export Component Development

✅ Why Choose Adhvika Forge Tech?

🏆 India’s leading forging consultant for power sector components

⚙️ Robust and scalable forging lines

💰 Cost-efficient machinery and die development

🔍 In-depth knowledge of electric power load and application behavior

🤝 Collaborative approach with EPC and component manufacturers

📞 Contact Us

Adhvika Forge Tech Pvt Ltd

📍 Bangalore (HO) | Jamshedpur (Factory)

📧 advikaforgetech@gmail.com

📞 +91-9801329640 / 080-22117198

🌐 www.adhvikaforgetech.com

#adhvikaforgetech #ElectricPowerForging #TurnkeyForgingSolution #ForgedWithUs #ElectricScrewPress #ShackleForging #PowerTransmissionParts #ClevisForging #MadeInIndia #HighTensionForging