How Turnkey Forging Solutions Save Time and Costs for New Forging Plants

Setting up a new forging plant demands significant investment, expertise, and flawless execution. Companies aiming to establish Open Die, Close Die, or Ring Rolling forging facilities often face project delays, cost overruns, and technical challenges.

This is where Turnkey Forging Solutions come into play.

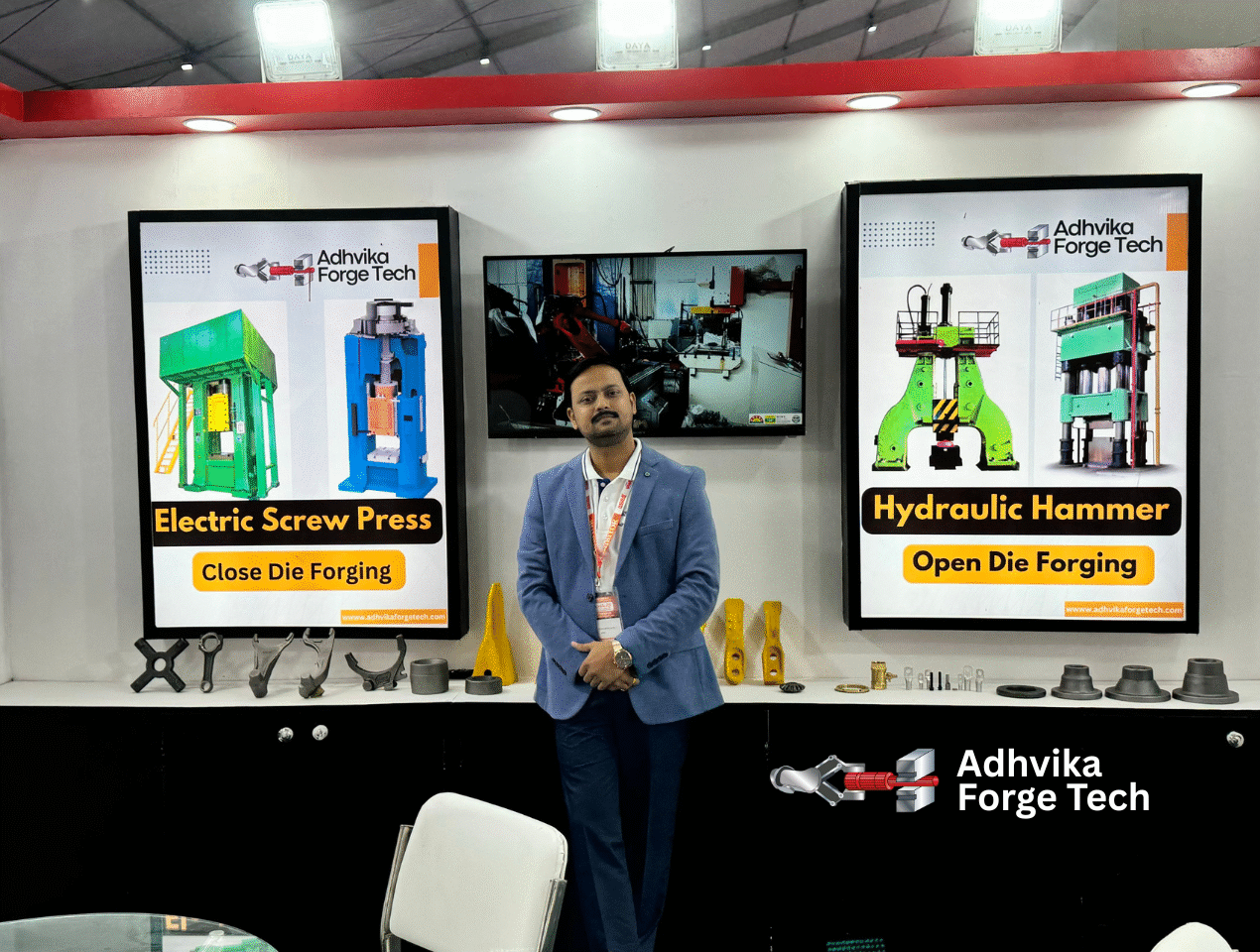

Leading turnkey providers like Adhvika Forge Tech Pvt. Ltd. deliver complete forging solutions — from machine supply, installation, overhauling, civil foundation work, to product development — ensuring fast project execution and high return on investment (ROI).

✅ 1. Single Window Management

Turnkey forging companies manage every aspect of the project:

Forging machine supply (Electric Screw Presses, Hydraulic Presses, Ring Rolling Machines)

Civil work for forging press foundation

Machine erection, trial runs, and process setup

Tooling and dies development

Product development support

Result:

🔹 No multi-vendor delays

🔹 Smooth coordination

🔹 Faster decision-making

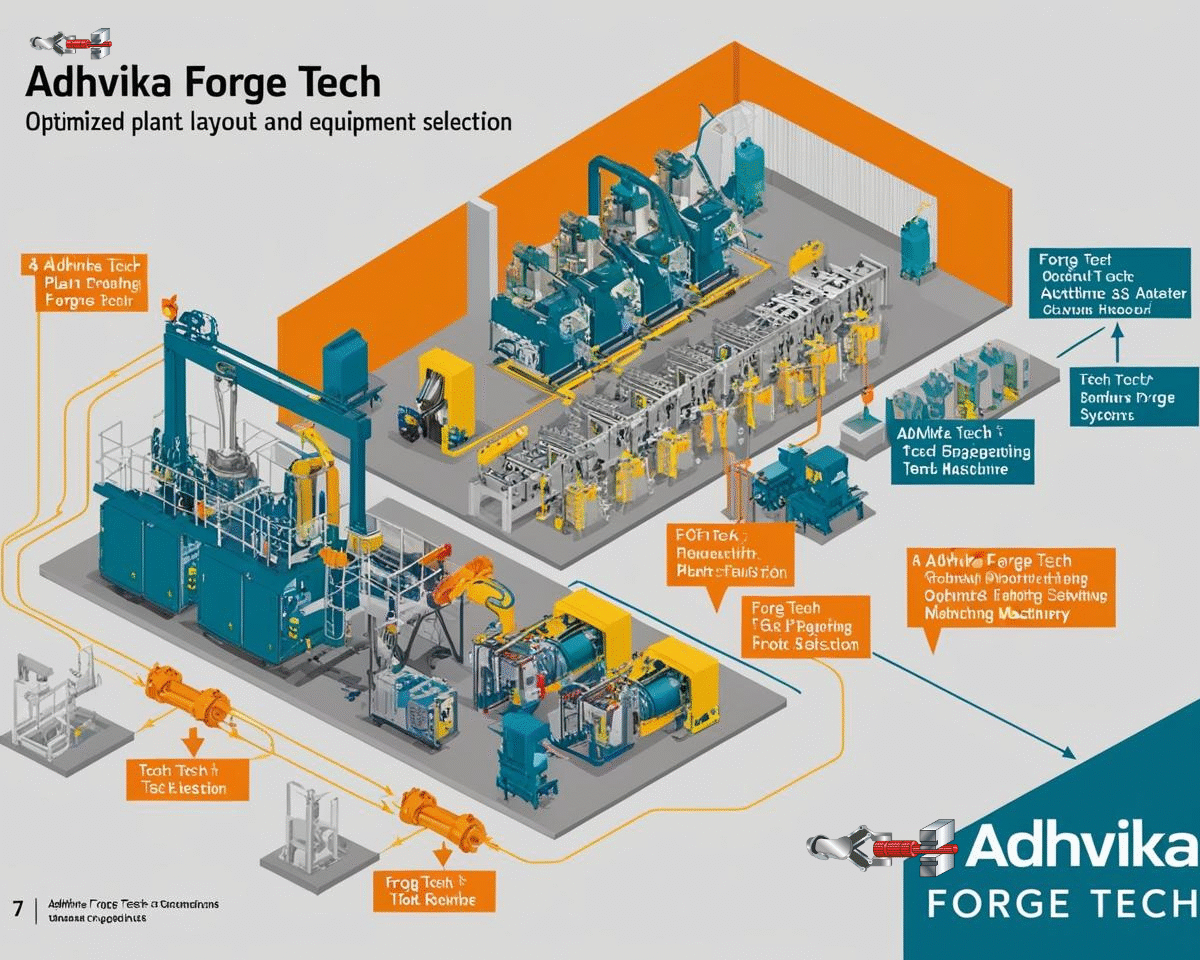

✅ 2. Optimized Plant Layout and Equipment Selection

Turnkey experts design efficient plant layouts based on production targets and workflow.

They select the right forging equipment, reduce roll machines, automation, and heating systems — customized to your application (automotive, aerospace, oil & gas, or defense).

Result:

🔹 Maximum space utilization

🔹 Reduced operational costs

🔹 Streamlined production flow

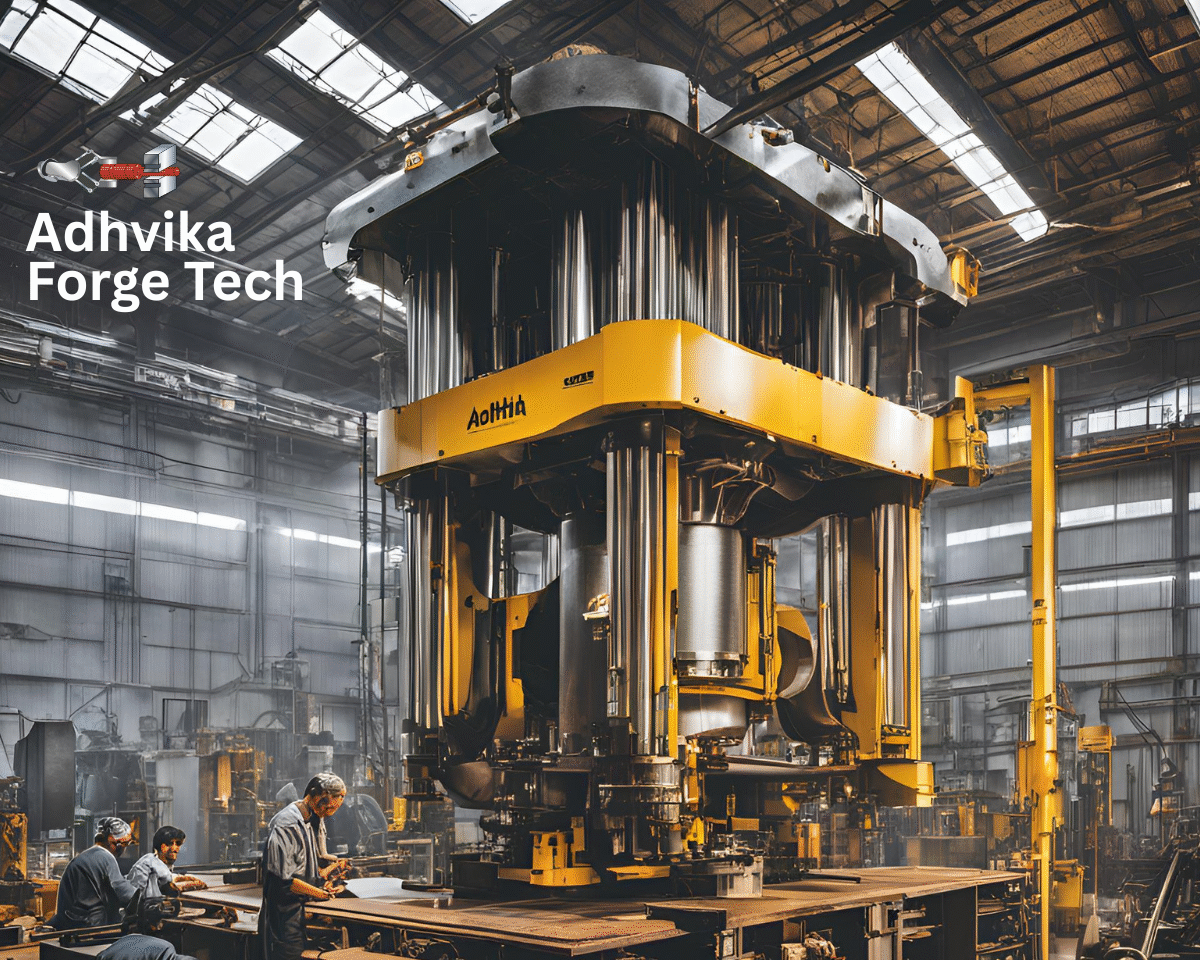

✅ 3. Faster Installation and Commissioning

Turnkey forging projects follow strict timelines for machine erection, calibration, and production trials.

With single-point accountability, startups become faster compared to traditional multi-vendor setups.

Result:

🔹 Plant ready in months, not years

🔹 Faster production kickoff

🔹 Quicker revenue realization

✅ 4. Transparent Project Costs and Budget Control

Turnkey forging partners offer pre-estimated costs for the full project including machines, civil work, erection, and support systems.

Bulk sourcing advantages lead to lower equipment and material costs.

Result:

🔹 Minimal hidden costs

🔹 Better financial planning

🔹 Higher project profitability

✅ 5. Ready Product Development and Technical Support

With Adhvika Forge Tech’s turnkey solution, you also get:

Forging process design

Die and tooling design

Metallurgical and heat treatment support

Prototype forging and production trial support

Result:

🔹 No R&D delays

🔹 Ready products for market

🔹 Stronger customer confidence

✅ 6. After-Sales Support and Training

Turnkey forging providers offer post-installation services including:

Preventive maintenance

Operator and maintenance team training

Emergency technical support

Result:

🔹 Reduced downtime

🔹 Better production efficiency

🔹 Long-term plant performance

Choosing Turnkey Forging Solutions with an expert like Adhvika Forge Tech Pvt. Ltd. reduces project risks, speeds up production launch, optimizes plant performance, and ensures better cost control.

Led by Amit Singh, India’s top forging consultant, Adhvika delivers world-class solutions for Open Die, Close Die, Ring Rolling, and Reduce Roll forging plants.

If you are planning a new forging plant or want to upgrade an existing facility, Adhvika Forge Tech provides the most cost-effective and time-saving turnkey solutions in India and globally.