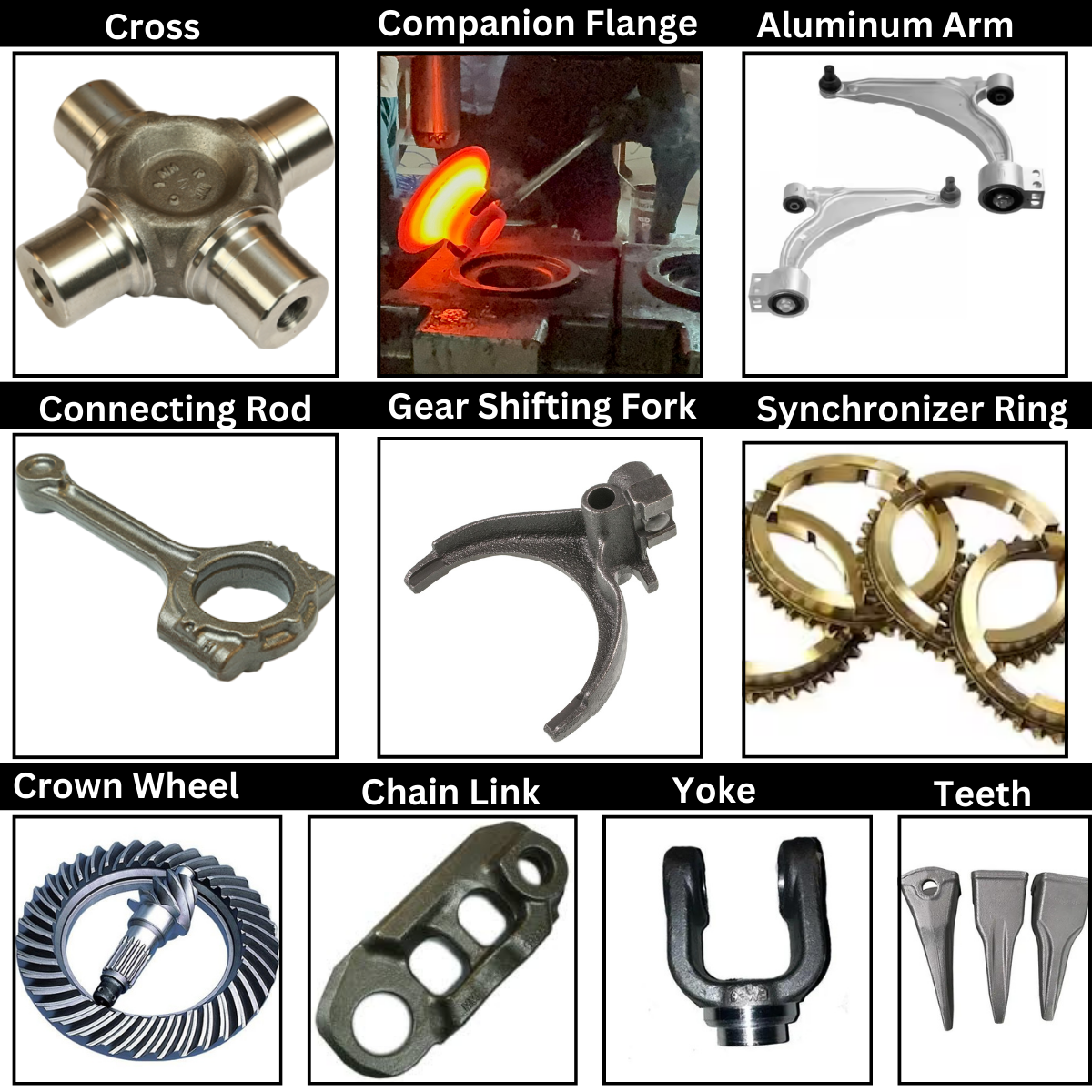

Automobile Forging: Types & Industry Applications

Automobile forging plays a crucial role in manufacturing strong, durable, and high-precision components used in vehicles. It enhances performance, safety, and longevity by producing parts that can withstand high stress and load conditions.

Key Industry Applications

🚗 Passenger Vehicles – Crankshafts, camshafts, gears, connecting rods, and steering components.

🚚 Commercial Vehicles – Heavy-duty axles, suspension parts, and transmission components.

🏍 Two-Wheelers – Forged gears, shafts, and connecting rods for motorcycles and scooters.

🚜 Agricultural Machinery – Tractor components, drive shafts, and gear systems.

🏎 Motorsports & EVs – Lightweight forged aluminum and titanium parts for high-performance and electric vehicles.

Types of Forging in the Automobile Industry

1️⃣ Open Die Forging – Used for large components like crankshafts and axles.

2️⃣ Closed Die Forging – Produces complex shapes with high accuracy, such as gears, connecting rods, and suspension parts.

3️⃣ Cold Forging – Ideal for high-volume production of small and strong components like fasteners and bearings.

4️⃣ Hot Forging – Used for parts requiring high strength and toughness, such as steering knuckles and transmission shafts.

5️⃣ Warm Forging – A combination of hot and cold forging for better surface finish and strength, commonly used for gears and wheel hubs.

6️⃣ Precision Forging – Produces near-net shape components, reducing material waste and machining costs.