Rear Shaft Forging | Axle Shaft Forging – Precision & Strength for Heavy-Duty Applications

Product Description

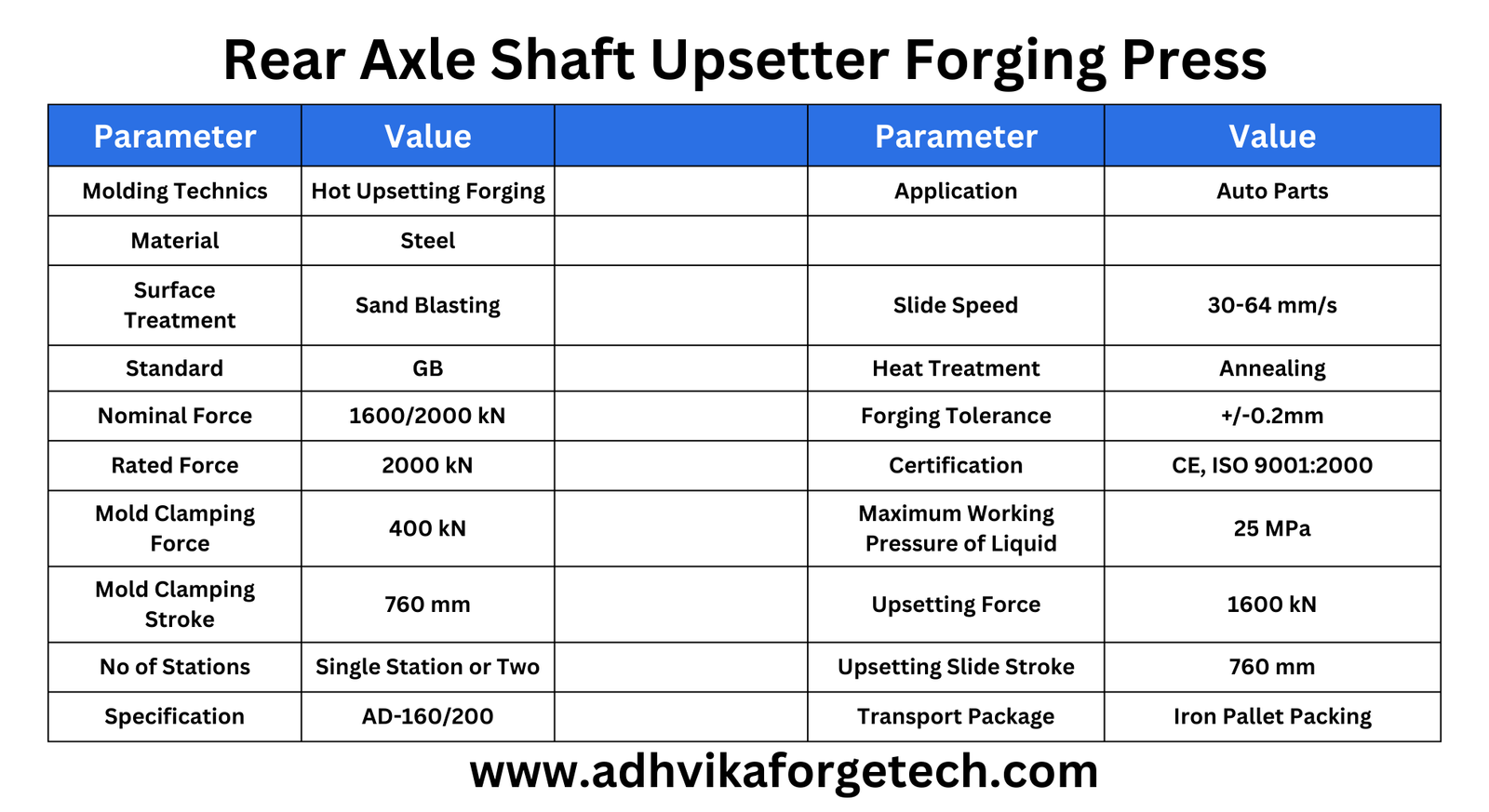

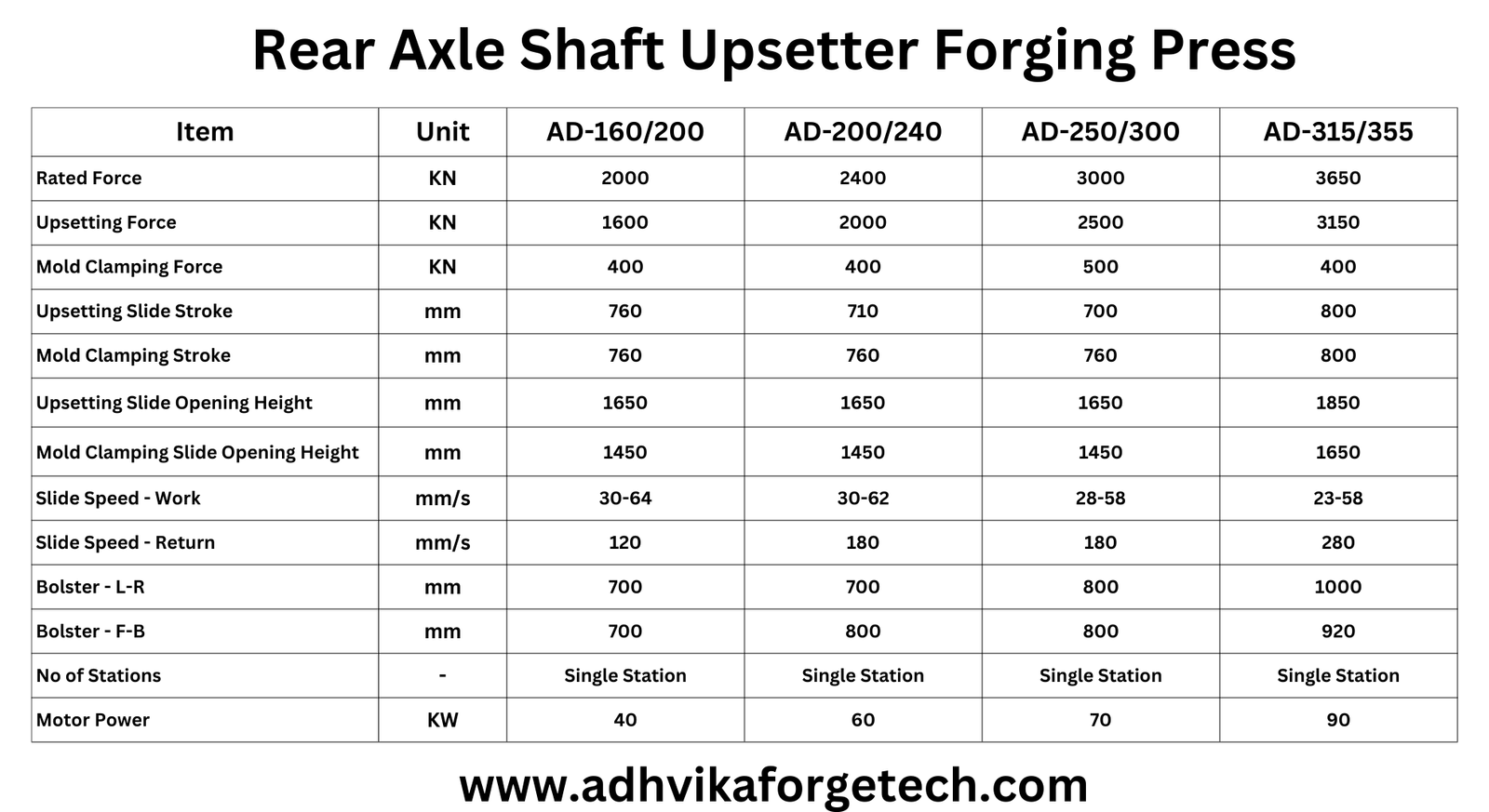

Hot Upsetting Forging Press Machine 160ton~315ton

Application: Applicable to the slender bar heating end upsetting process for hot preset forming of auto half shaft flange end and multiple spline,and other preset of heating rod bar, popular in the industries of autos, tractors, ships, and etc .

Features:

* There is a single and double stations optional , adopt hydraulic, electrical control, and centralized button control, can be realize adjustable, semi-automatic, automatic three kinds of operation models.

* Adopts four-column single or double-action structure, with rapid clamping speed ,and clamping force adjustable.

* Fixture adopts hydraulic driven, electric control system adopts imported PLC control, with high degree of automation, high speed of pressing , small temperature change after upsetting, which can be for rotary forging directly after heating , to improve work efficiency and save cost.

Adhvika Forge Tech specializes in Rear Shaft & Axle Shaft Forging, delivering high-strength, precision-forged components for automotive & industrial applications.

Rear Shaft Forging | Axle Shaft Forging – High Strength & Durability

🔹 About Our Forged Rear & Axle Shafts

Adhvika Forge Tech, we specialize in precision-engineered rear shafts and axle shafts, ensuring superior strength, durability, and performance.

Our closed die and open die forging processes produce high-quality axle shafts for automotive, heavy-duty, and industrial applications.

Our advanced forging technology provides high load-bearing capacity, fatigue resistance, and optimized grain flow, making our shafts the best choice for high-performance vehicles and machinery.

🔹 Key Features of Our Forged Shafts

✅ High Strength & Impact Resistance – Ensures longer lifespan and reliability.

✅ Precision Machining & Heat Treatment – Optimized for superior performance.

✅ High Load-Bearing Capacity – Perfect for heavy-duty applications.

✅ Material Efficiency & Grain Flow Optimization – Reduces material wastage.

✅ Custom Sizes & Specifications Available – Tailored solutions for all industries.

🔹 Applications of Rear & Axle Shaft Forging

🔹 Automotive & Commercial Vehicles

🔹 Heavy-Duty Trucks & Trailers

🔹 Construction & Mining Equipment

🔹 Agricultural Machinery

🔹 Off-Road & Industrial Vehicles

🔹 Why Choose Adhvika Forge Tech ?

✔ State-of-the-Art Forging Facilities

✔ Advanced CNC Machining & Heat Treatment

✔ Custom Design & Engineering Support

✔ Reliable & Cost-Effective Forging Solutions

✔ Global Supply & On-Time Delivery

📞 Looking for high-performance forged rear shafts & axle shafts?

Contact Adhvika Forge Tech today!