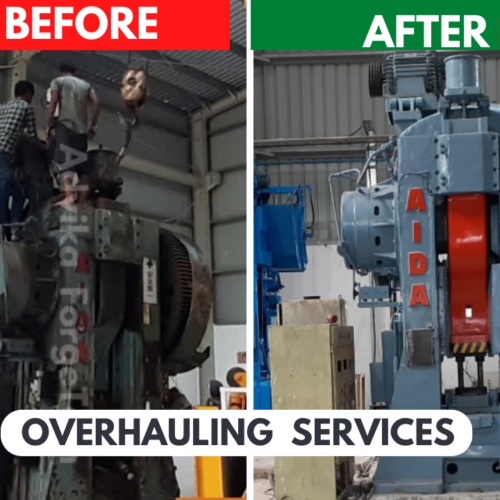

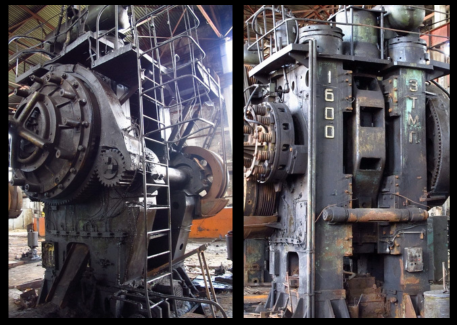

Our Project: Mechanical Press Overhauling – 1000 Ton & 1600 Ton (Bangalore)

Adhvika Forge Tech has successfully undertaken the overhauling and commissioning of 1000 Ton & 1600 Ton Mechanical Presses in Bangalore. Our expertise ensured seamless execution from dismantling to production-ready operations.

We specialize in overhauling, shifting, installation, commissioning, and automation of all types of forging machines, ensuring top performance and extended machine life. Our expertise covers a wide range of forging equipment, delivering cost-effective and high-quality solutions.

Our Overhauling Process – Step by Step

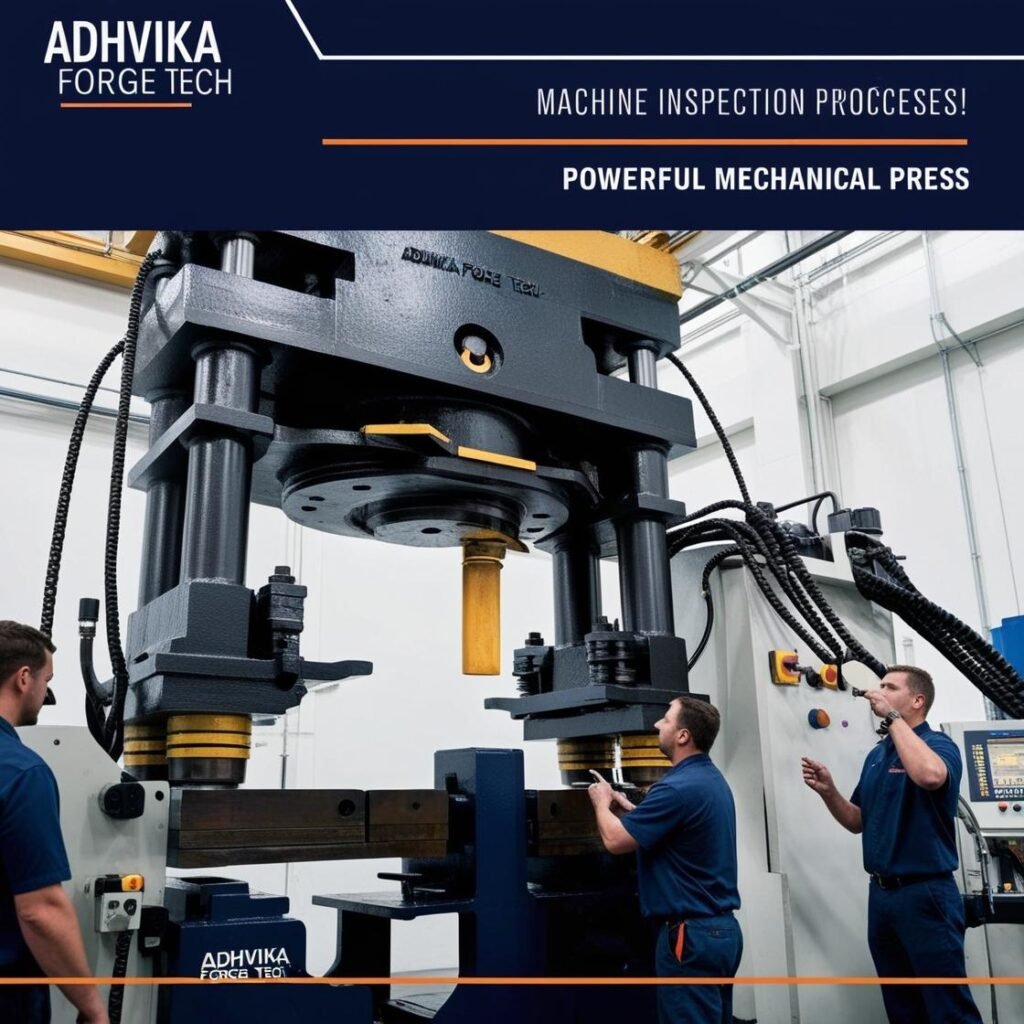

Step 1: Machine Inspection & Analysis

✅ Our team inspects the machine on-site to check for wear, damage, and operational issues.

✅ We analyze key components, including frames, gears, bearings, and electrical systems.

✅ A detailed overhauling plan is prepared based on the findings.

Step 3: Refurbishment & Repairs

✅ Worn-out parts like gears, clutch systems, hydraulic cylinders, and electrical components are replaced or repaired.

✅ Lubrication systems are cleaned, and new oiling mechanisms are installed.

✅ Structural repairs and repainting are done to improve machine durability.

🔹 Step 2: Machine Dismantling & Shifting

✅ If required, the machine is carefully dismantled for repair or relocation.

✅ Shifting & transportation are done with proper safety measures.

✅ The foundation is checked to ensure it is strong and stable.

Step 4: Reinstallation & Alignment

✅ The overhauled machine is reinstalled in the workshop.

✅ Proper alignment and leveling are ensured for smooth operation.

✅ Electrical & hydraulic connections are checked for leak-proof and safe functioning.

Step 5: Commissioning & Trial Run

✅ Power testing and load trials are conducted to check press efficiency.

✅ Fine-tuning is done for smooth working and high accuracy.

✅ The machine is handed over with full operational support.

Step 6: Job Development & Training

✅ We assist in forging part development under the overhauled machine.

✅ Operator training is provided for maintenance and best usage practices.

✅ Regular after-sales support is offered for troubleshooting.

Our Overhauling & Installation Services:

✅ Mechanical Press Overhauling – Complete servicing & performance enhancement.

✅ Hydraulic Press Overhauling – Ensuring smooth operation & power efficiency.

✅ Electric Screw Press Overhauling – Upgrading for precision & energy savings.

✅ Hammer Overhauling (All Types) – Repair & reconditioning for extended durability.

✅ Shifting & Relocation Works – Safe & efficient machine transport & setup.

✅ Installation & Commissioning – End-to-end support for seamless operations.

✅ Automation & Control System Upgrades – Enhancing production efficiency.

✅ Forging Material Handling Solutions – Custom setups for smooth workflow.

💡 Need Reliable Overhauling & Installation Services? We’re here to help!