Open Die Forging Machine

Pneumatic Hammer

Offers fast, controlled strikes, perfect for flexible, high-speed…

Double Column Hammer

Provides high stability and power, ideal for heavy …

C-Frame Hammer

Compact, efficient for open die forging with easy access…

Hydraulic Press

Precise force for large, ensuring superior metal flow and strength…

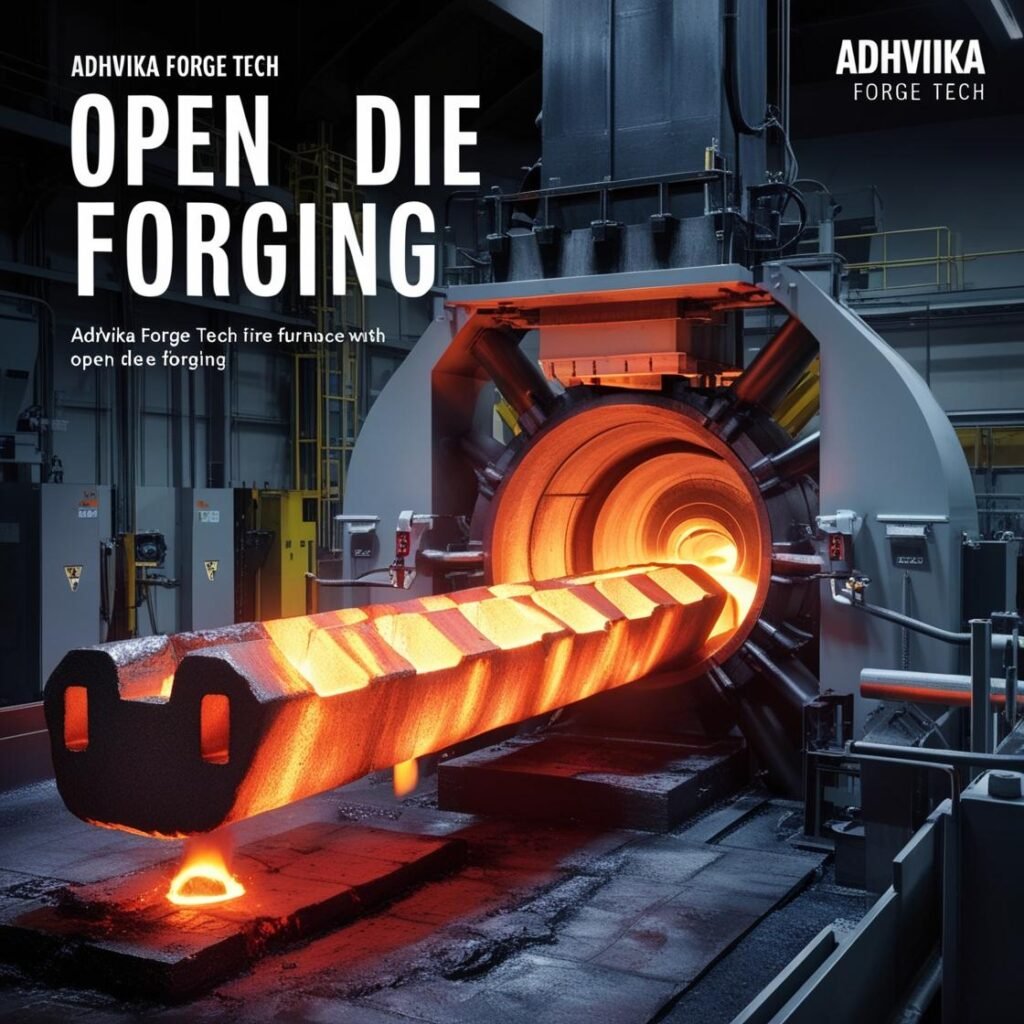

Open Die Forging: How Adhvika Forge Tech Delivers Excellence

🚀 Adhvika Forge Tech’s Open Die Forging Process:

- Material Selection:

We start by selecting premium raw materials like EN24, aluminum alloys, titanium, and high-strength steels to ensure product durability. - Precision Heating:

The material is heated uniformly in advanced furnaces to achieve optimal forging temperatures, reducing the risk of material defects.

Forging Operations:

Using Double Column Hammers and Hydraulic Presses, we shape the metal with precision, maintaining excellent grain flow for maximum strength.- Double Column Hammer: Best for shafts, flanges, and heavy components.

- Wagner Ring Rolling Machine: Capable of producing rings up to 1500 mm OD, ensuring high material savings.

Finishing & Heat Treatment:

After forging, we provide in-house machining, heat treatment, and stress relieving to meet exact mechanical properties.- Quality Assurance:

Every component undergoes rigorous NDT (Non-Destructive Testing), dimensional inspections, and metallurgical analysis to meet international standards.

💡 Why Choose Adhvika Forge Tech for Open Die Forging?

💡 Why Choose Adhvika Forge Tech for Open Die Forging?

High accuracy with advanced forging machines

Energy and material savings through optimized processes

Quick ROI with cost-effective machinery solutions

Strong after-sales support with service centers in India & China