Hot Forging Press Machine | Screw Press | Mechanical Press

Screw Press - SRD Type

Mechanical Press

Hot forging is a critical process in the manufacturing and metal forming industry, offering superior mechanical properties, strength, and reliability compared to casting or machining. Hot Forging Press Machines, such as Screw Presses and Mechanical Presses, are widely used for shaping metals into precise components, ranging from automotive shafts, flanges, and gears to aerospace, defense, and heavy industrial applications.

Types of Hot Forging Press Machines

Screw Press (Electric / Mechanical):

Screw presses operate by rotating a screw (usually a ball screw) connected to a flywheel or servo motor. This converts rotational motion into linear pressing force applied to the workpiece. The screw press provides precise control over the forging stroke, speed, and energy distribution. It is ideal for medium to high tonnage operations, providing excellent repeatability, high accuracy, and energy-efficient operation. Typical tonnages range from 250 Tons to 8500 Tons, suitable for ferrous and non-ferrous metals like steel, aluminum, titanium, and alloy steels.

Mechanical Press:

Mechanical presses are driven by flywheels, cranks, or eccentric mechanisms, converting rotary motion into a linear press. They are capable of high-speed forging operations, producing large volumes with consistent quality. Mechanical presses are available in capacities from 100 Tons to 12500 Tons and can be used for open die and closed die forging, making them versatile for various industrial applications.

Forging Range & Capacity

Hot forging press machines are capable of processing a wide range of metals and alloys, including steel, alloy steel, aluminum, titanium, and Inconel, in various shapes such as shafts, flanges, gears, couplers, and industrial components. They accommodate small precision parts to large industrial components, with tonnage ranging from 250 Tons up to 8500 Tons, depending on the press type and material specifications.

Forging Like below Components:

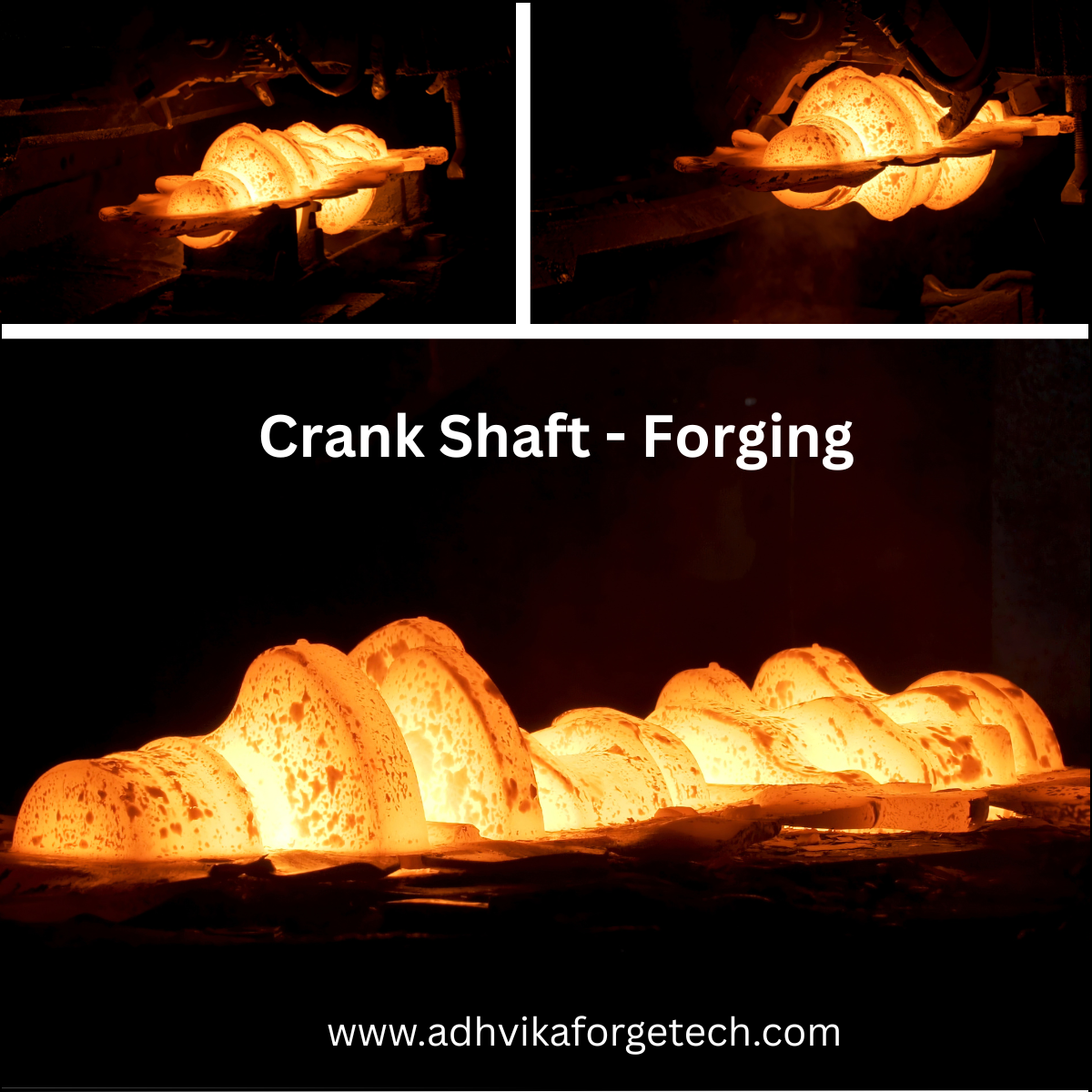

- Crankshafts

- Camshafts

- Gears (Spur, Helical, Bevel, Pinion)

- Shafts (Transmission, Drive, Axle)

- Flanges (Pipe Flanges, Neck Flanges)

- Couplers (Railway, Industrial)

- Yokes (Universal Joint Yokes, Steering Yokes)

- Bucket Teeth (Excavator / Loader)

- Connecting Rods (Engine / Heavy Machinery)

- Wheel Hubs

- Valve Bodies (Oil & Gas / Engine Valves)

- Bomb Shells (Defense Forgings)

- Propeller Shafts

- Tie Rod Ends

- King Pins (Automobile / Heavy Vehicle)

- Spur Wheels / Pinions (Industrial / Railway)

- Rollers (Forged Rollers for Rolling Mills)

- Hydraulic Cylinder Rods

- Axle Boxes (Railway / Heavy Vehicles)

- Gear Blanks (for further machining or finishing)

Medical Item

Adhvika Forge Tech, we offer complete turnkey forging solutions, from press selection, die design, forging trials, automation integration, and final component development. Our solutions include:

Open Die Forging & Close Die Forging: Optimized for strength, precision, and yield.

Automation Integration: Robotic handling, material feeders, and forging line automation.

Die Design & Simulation: 3D simulation to optimize flow, reduce defects, and improve efficiency.

Energy Efficiency & Yield Optimization: Modern presses designed for low energy consumption and maximum material utilization.

Custom Forging Solutions: For automotive, defense, aerospace, medical implants, and industrial components.

We ensure that every press, whether screw press or mechanical press, meets international standards, delivering consistent performance, high production rates, and precise forging results. Our team provides on-site installation, commissioning, maintenance, and technical support, ensuring smooth operations and long-term reliability.

With Adhvika Forge Tech, clients gain access to wide-ranging forging capacities, from 1 Ton pneumatic hammers to 8500 Ton screw presses, covering small to heavy industrial components. Our expertise in material handling, press technology, and process optimization ensures that every forging project achieves the highest quality and cost-effectiveness.