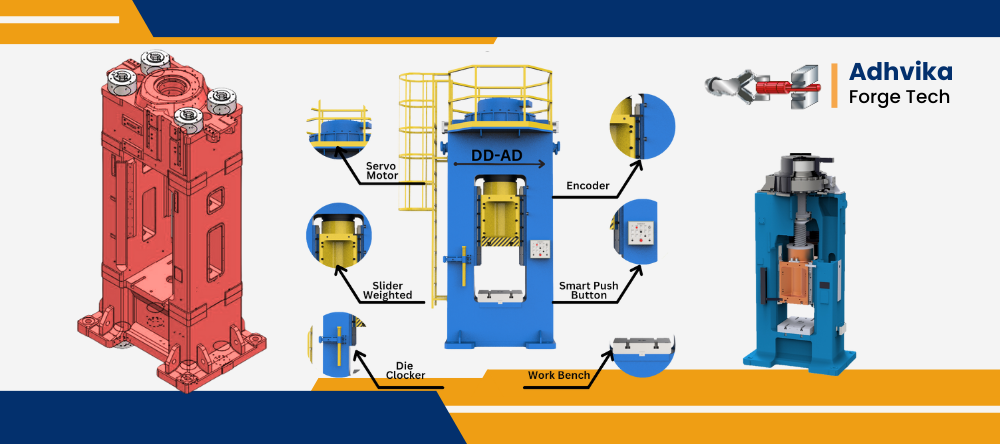

Servo Screw Press – Power Meets Accuracy

What Is Servo Press ?

A servo screw press is a type of mechanical press driven by a servo motor that rotates a screw (usually a ball screw or similar) to convert rotational motion into precise vertical movement for pressing operations. Unlike traditional screw presses driven by friction or mechanical clutch systems, the servo screw press uses an electric servo motor to provide accurate control over the ram’s position, speed, and force during the press cycle.

Key Characteristics of a Servo Screw Press:

The servo motor transmits torque to the ball screw shaft, which moves the ram up and down with high precision.

Load cells often monitor the pressing force in real time, allowing dynamic control and feedback.

The ram’s speed and pressure can be precisely programmed and controlled at any point in the stroke.

Energy-efficient operation since the motor runs on-demand only during pressing.

Reduced mechanical wear and tear compared to friction-drive systems.

Regenerative braking converts kinetic energy during the ram’s return stroke back into electrical energy.

High repeatability and accuracy lead to improved product quality and lower scrap rates.

Often used in forging, metal forming, and precision stamping applications.

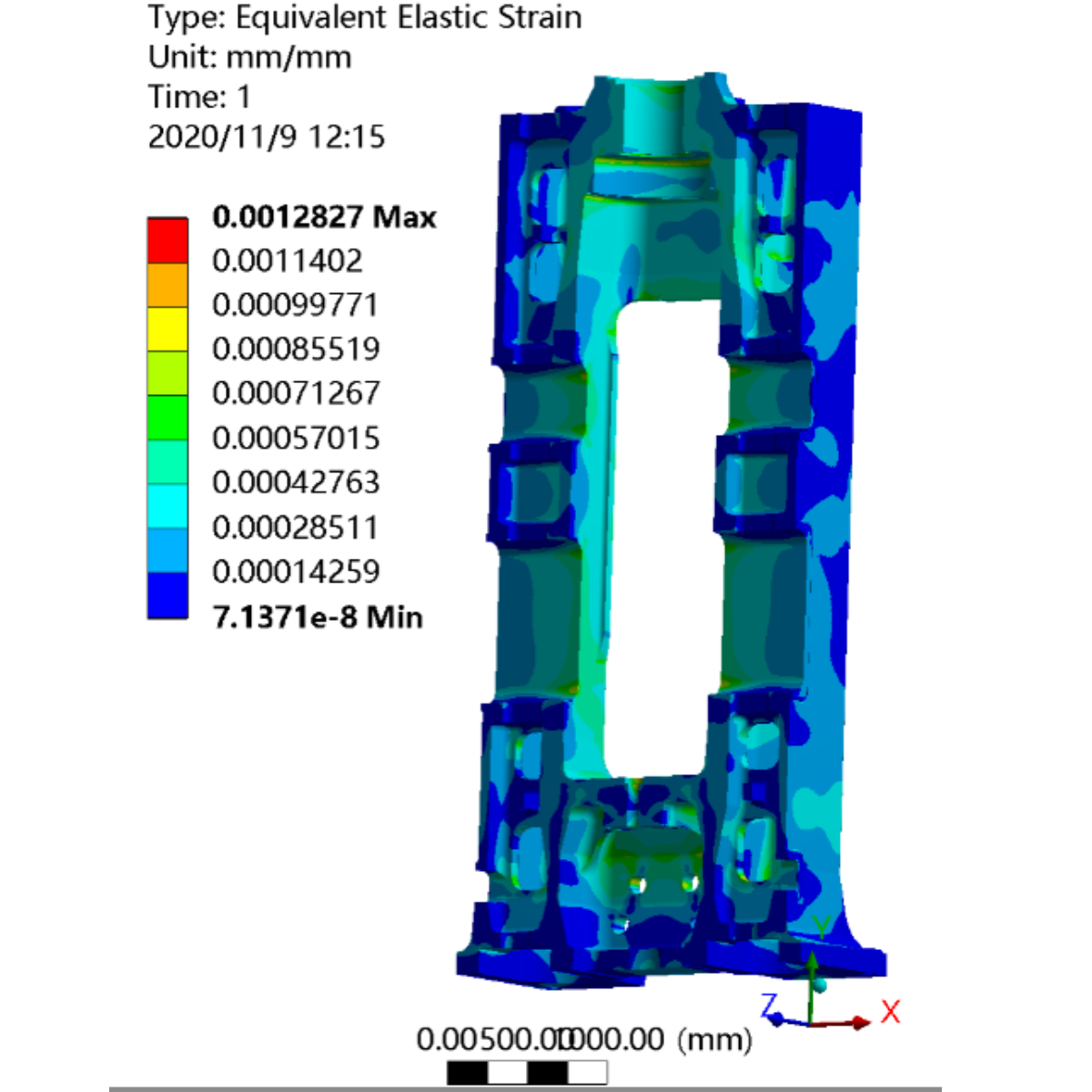

Single Casting Body

The single-body casting of an Electric Screw Press ensures high structural rigidity, reduces vibrations, and maintains precise alignment, enhancing press accuracy and long-term durability.

The single-body casting of an Electric Screw Press is designed for maximum rigidity and strength, minimizing vibrations and deflections during operation. This ensures precise alignment of the screw and ram, maintaining high forging accuracy and consistency. By reducing mechanical stresses and enhancing structural stability, the single-body casting improves the machine’s durability, reliability, and service life, making it ideal for high-precision forging applications.

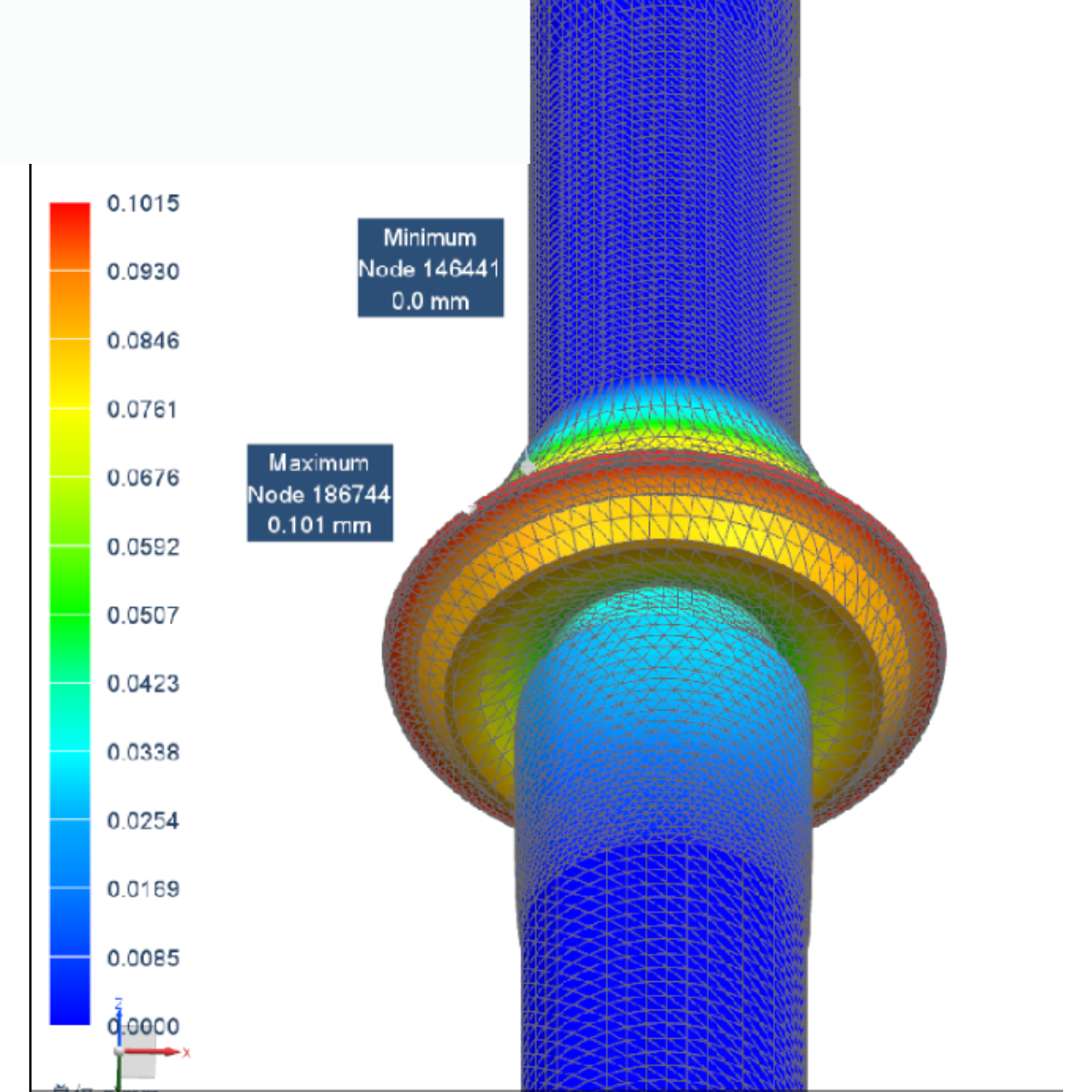

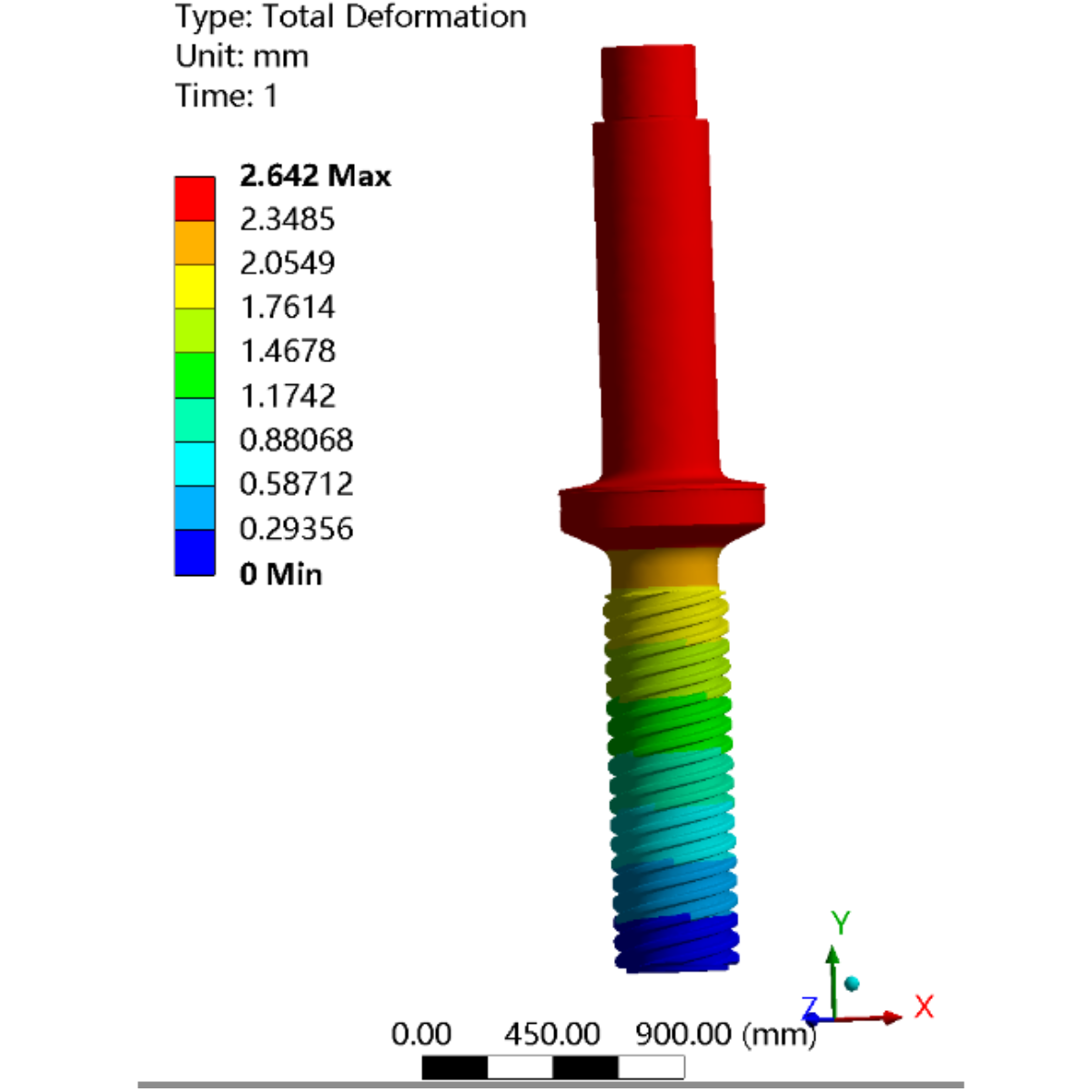

Lead Screw – Bearing Area Pressure

In an Electric Screw Press, the lead screw impact area is designed to sustain high bearing loads, ensuring maximum forging capability. This critical zone absorbs and distributes forces during pressing, minimizing stress on the screw and ram. By efficiently handling high-impact loads, it maintains precision, reduces wear, and allows consistent, high-capacity forging operations, ensuring long service life and reliable performance for demanding industrial applications.

High-Pressure Lead Screw Area – Precision Forging & Quality Assurance

The lead screw area of an Electric Screw Press is a high-pressure zone, responsible for lifting the ram/slider and sustaining heavy forces during forging.

To ensure maximum strength and durability, the lead screw undergoes pre-forging in a hydraulic press, followed by a sizzling process to refine material properties. After manufacturing, ultrasonic testing is performed to detect any cracks or defects, ensuring reliability, long service life, and consistent high-capacity forging performance in demanding industrial applications.

In summary:

The servo motor powers a ball screw to convert rotational motion into precise vertical ram movement.

The ram force is constantly monitored by sensors for real-time pressure control.

The press stroke, speed, and force are programmable for complex forming processes.

The system uses energy only when pressing, offering high efficiency and low maintenance.

This precise control improves product quality and reduces wear compared to traditional mechanical presses.