Electric Screw Press | Direct Drive Precision Forging Solutions

Adhvika Forge Tech’s electric screw press harnesses advanced direct drive servo motor technology and ABB inverter drives to deliver unparalleled precision, energy efficiency, and reliability for modern forging applications. Designed for automotive, aerospace, defense, and industrial manufacturing, our presses convert rotational power directly into controlled linear force—eliminating mechanical losses, reducing energy consumption by up to 40%, and achieving ±0.1 mm stroke accuracy. With Siemens PLC integration, turnkey automation options, and Industry 4.0–ready connectivity, this electric screw press redefines productivity, die life, and total cost of ownership for high-performance forging operations.

We are specializes in high-quality Electric Screw press machines designed for precise and efficient forging operations. Our electric screw presses deliver superior energy efficiency, precision control, and durability for various industrial applications.

Introduction Of Electric Screw Press

The Electric Screw Press is a high-precision forging machine widely used in industrial metal forming. Built for reliability and efficiency, it offers numerous advantages such as precise force control, durability, and energy savings.

AD Series Electric Screw Press is designed for high-precision forging, sizing, pressing, calibration, and leveling applications. It ensures accurate energy control, allowing precise forging results. The press operates with a short stroke and stable energy output, reducing mechanical and thermal stress on forging dies, which helps in prolonging their lifespan.

One of the key benefits of this press is its ability to adjust hitting energy based on the metal forming needs. This makes it highly efficient and suitable for a wide range of forging processes, including precision components and complex shapes.

Additionally, due to its low slider speed, this press has unique advantages in forging non-ferrous metals such as aluminum alloys and copper, ensuring high-quality results with minimal material waste.

Our AD Series Electric Screw Press is built using advanced frequency conversion control technology, making it highly efficient, reliable, and easy to operate. It delivers higher working energy, making it a perfect choice for various industrial forging applications.

With its simple and robust design, this press is widely used in modern forging production, ensuring high productivity, energy savings, and long-lasting performance.

Electric Screw Press Bloc Diagram

Parameter of Electric Screw Press

| Item | Unit | J58K-160 | J58K-250 | J58K-315 | J58K-400 | J58K-630 | J58K-1000 | J58K-1600 | J58K-2500 | J58K-4000 |

| Nominal force | KN | 1600 | 2500 | 3150 | 4000 | 6300 | 10000 | 16000 | 25000 | 40000 |

| Max. working force | KN | 2500 | 4000 | 5000 | 6300 | 10000 | 16000 | 25000 | 40000 | 63000 |

| Max. forging energy | KJ | 10 | 15 | 20 | 40 | 80 | 160 | 280 | 500 | 1000 |

| Slide stroke | mm | 300 | 320 | 380 | 400 | 450 | 580 | 600 | 630 | 750 |

| Theoretical strokes | min⁻¹ | 30 | 28 | 26 | 20 | 19 | 18 | 15 | 14 | 10 |

| Min. enclose height | mm | 500 | 520 | 550 | 570 | 720 | 870 | 960 | 1050 | 1460 |

| Thickness of sow block | mm | 120 | 120 | 120 | 120 | 160 | 180 | 220 | 250 | 300 |

| Enclose height range of die | mm | 380 ~ | 380 ~ | 430 ~ | 450 ~ | 560 ~ | 570 ~ | 740 ~ | 800 ~ | 1160 ~ |

| Size of worktable (width x depth) | mm | 600×560 | 600×560 | 700×640 | 750×730 | 820×900 | 920×1050 | 1000×1280 | 1200×1400 | 1600×1900 |

Working Principle of Electric Screw Press

Electric Screw Press (ESP) works on the principle of rotational energy conversion into linear motion using a servo motor or direct-drive motor. This modern design replaces the traditional friction wheel mechanism with a motor-driven screw system, providing precise control, high energy efficiency, and consistent forging quality.

Step-by-Step Working Process

- Motor Activation

- A servo-controlled electric motor or direct-drive motor starts the operation.

- The motor provides rotational motion to the screw shaft without the need for belts or gears.

- Rotational to Linear Motion Conversion

- The rotating screw spindle converts rotational energy into vertical linear motion through a ram or slider mechanism.

- This ram moves up and down with precise control of force and stroke length.

- Forging Stroke Execution

- The ram strikes the workpiece placed on the anvil or die block with controlled impact energy.

- Operators can adjust the blow energy according to material thickness, part geometry, and forging requirements.

- Reverse Motion & Quick Return

- After each forging stroke, the motor reverses direction, lifting the ram back to the starting position.

- This allows fast stroke cycles for high productivity.

- Automation & Precision Control

- With Siemens PLCs and ABB inverters, parameters like blow speed, stroke length, and number of hits can be set in advance.

- Integration with robots and manipulators enables fully automatic forging lines.

Key Advantages of This Working Principle

- Energy Efficiency: No energy loss due to friction wheels or gears—direct power transfer reduces electricity consumption by 30–40%.

- Precision Control: Servo motors and PLC systems ensure accurate forging force and position for complex parts.

- Low Maintenance: Fewer mechanical parts mean reduced wear-and-tear and longer machine life.

- Extended Die Life: Controlled impact reduces sudden shocks on dies, increasing die life by 20–30%.

- High Production Rates: Quick stroke cycles combined with automation result in higher output per shift.

Electric Screw Press transforms traditional forging with its motor-driven, precision-controlled system. Its working principle ensures better energy efficiency, superior forging accuracy, low maintenance, and automation readiness, making it the future of modern forging industries.

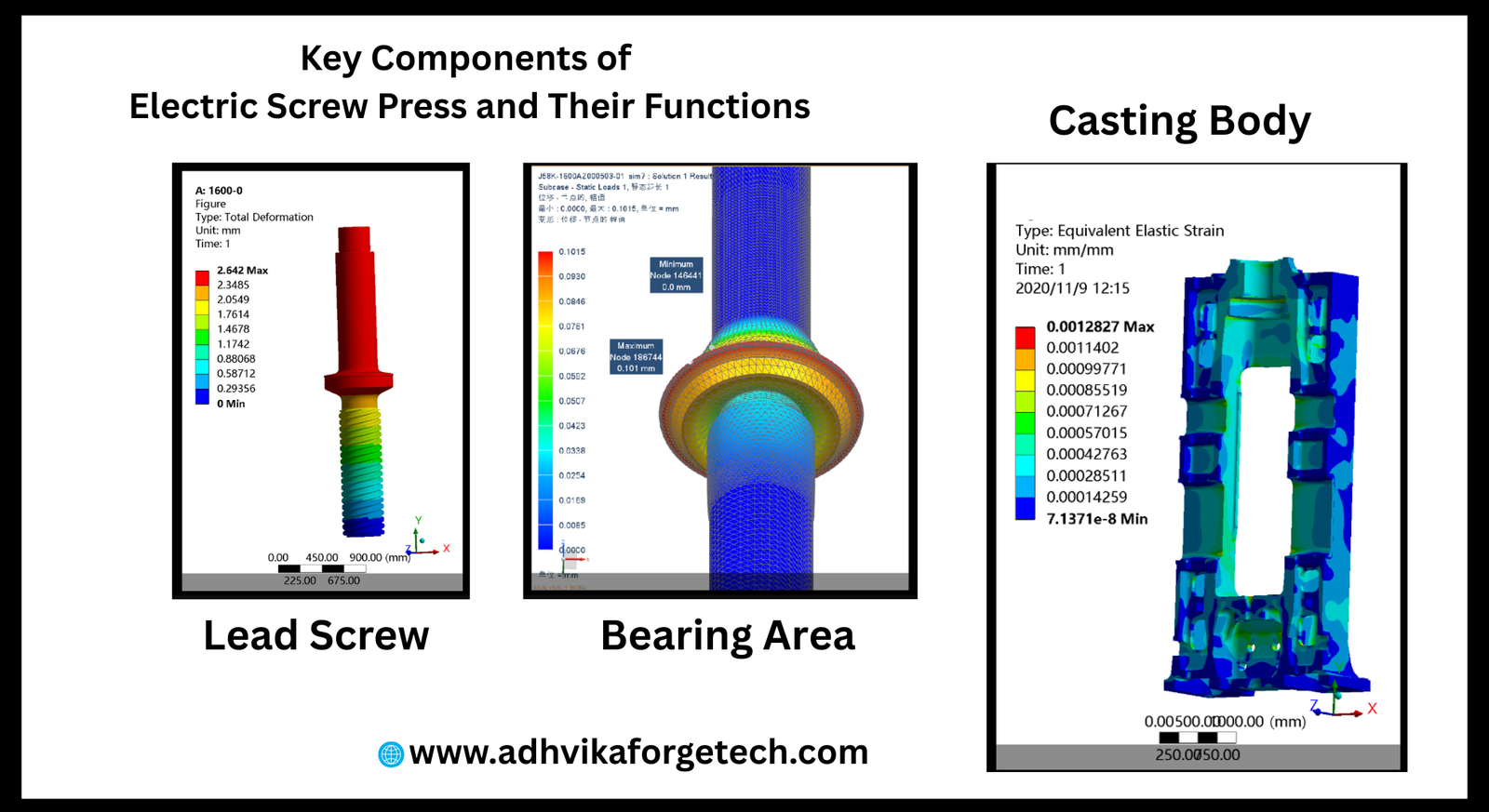

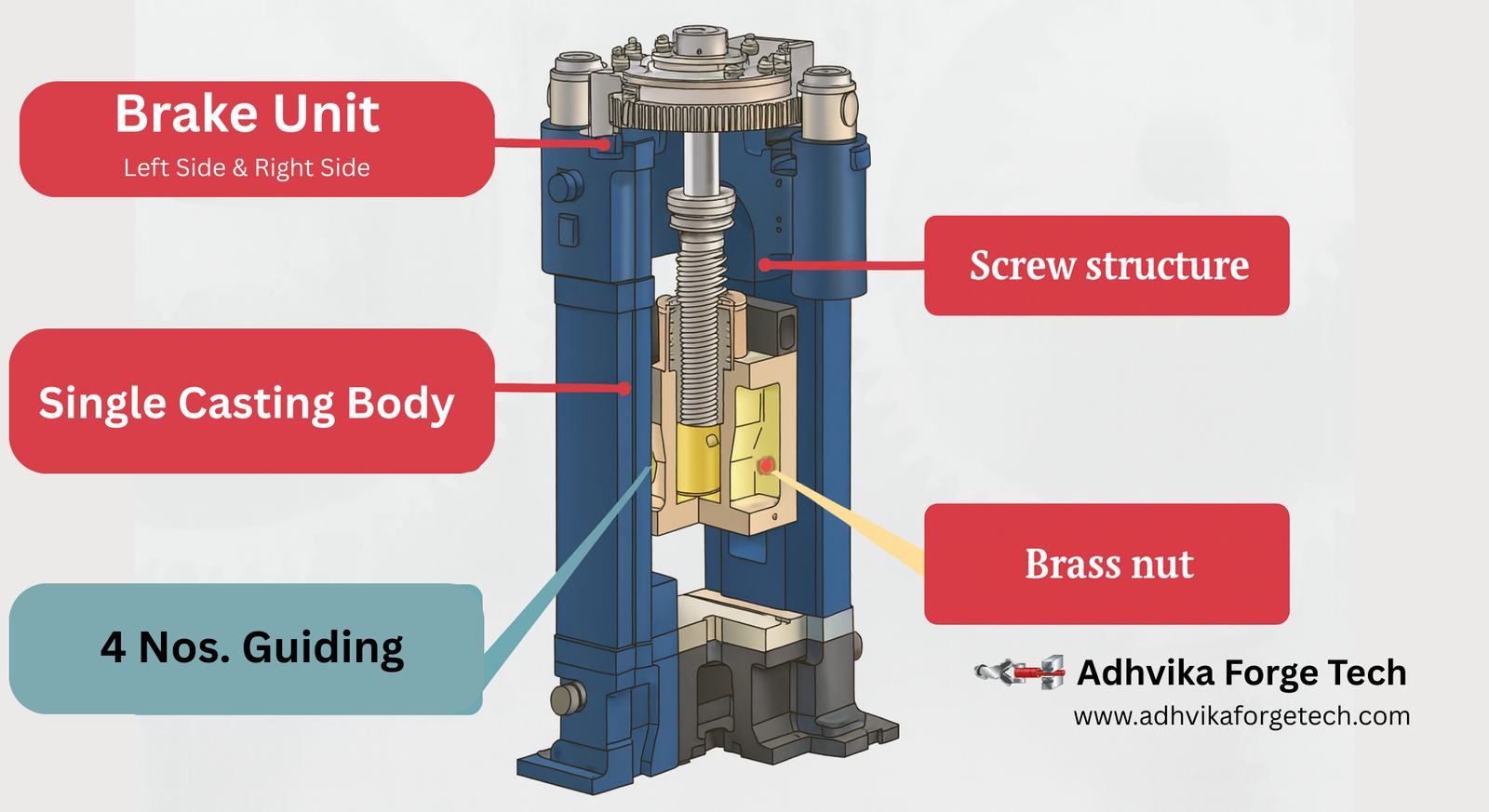

1. Screw Structure – High-Strength Design for Maximum Rigidity

The screw in the Electric Screw Press is made from CrMoV high-alloy forging steel, renowned for its excellent fatigue resistance and durability. Its non-self-locking thread type ensures smooth and stable motion without jamming, while the short screw design enhances the rigidity of the press frame, reducing deflection during heavy forging operations. This results in greater dimensional accuracy, longer machine life, and improved forging quality.

2. Nut – Precision Bronze Alloy for Smooth Performance

The nut, manufactured from high-strength bronze alloy, is mounted inside the slide assembly. This material choice ensures superior wear resistance and emergency sliding capabilities even under high loads and elevated temperatures. It provides consistent lubrication retention, resulting in smoother motion, reduced friction, and minimal maintenance requirements throughout the machine’s operating life.

3. Slide Block – Robust Construction for Stability

The slide block is produced using high-grade steel casting that undergoes full aging heat treatment to relieve internal stresses generated during casting. This process guarantees dimensional stability and prevents deformation under repetitive forging forces. Its robust construction allows it to withstand high impact loads, ensuring machine stability, accuracy, and long-term performance.

4. Guiding System – Precision Guidance for Enhanced Die Life

The guiding system is designed with a 45-degree arrangement relative to the slide block surface, ensuring constant clearance that remains unaffected by thermal expansion during high-temperature forging operations.

Key features include:

Guide Materials: Combination of bronze and hardened steel for high wear resistance.

Nitrogen-Treated Guide Rail: Increases surface hardness and resistance to abrasion.

Adjustable Guide Plates: Allow multi-directional clearance adjustments to maintain optimal guiding accuracy.

High Rigidity & Optimal Guiding Length: Prevents misalignment, reduces vibrations, and ensures long die life with high-quality forging outputs.

5. Integrated System Performance – Durability Meets Precision

All these components—screw, nut, slide block, and guiding system—are designed to work in perfect synchronization, offering:

High Structural Rigidity for precision forging

Smooth and Stable Motion for consistent production quality

Low Maintenance Requirements with long service intervals

Extended Tool and Die Life, reducing overall production costs

This integrated engineering approach ensures that the Electric Screw Press delivers maximum productivity, minimal downtime, and outstanding reliability for modern forging operations.

Futures of Electric Screw Press

Energy Efficiency – Uses inverter drives for power saving and reduced electricity consumption. ⚡

Precision Control – Offers accurate stroke control for high-quality forging. 🎯

Low Maintenance – Fewer moving parts compared to mechanical presses, reducing wear and tear. 🛠️

High Productivity – Fast cycle times enable mass production with minimal downtime. ⏱️

Versatile Applications – Suitable for closed-die forging, coining, and precision forming. 🏭

Programmable Operations – Easy integration with PLC/automation for flexible production. 🤖

Compact Design – Requires less floor space compared to traditional forging hammers. 📏

Quiet Operation – Less noise and vibration for improved workplace environment. 🔇

Consistent Forging Quality – Maintains uniform force application for better product consistency. 📦

Safety Features – Equipped with advanced braking and overload protection systems. 🛡️

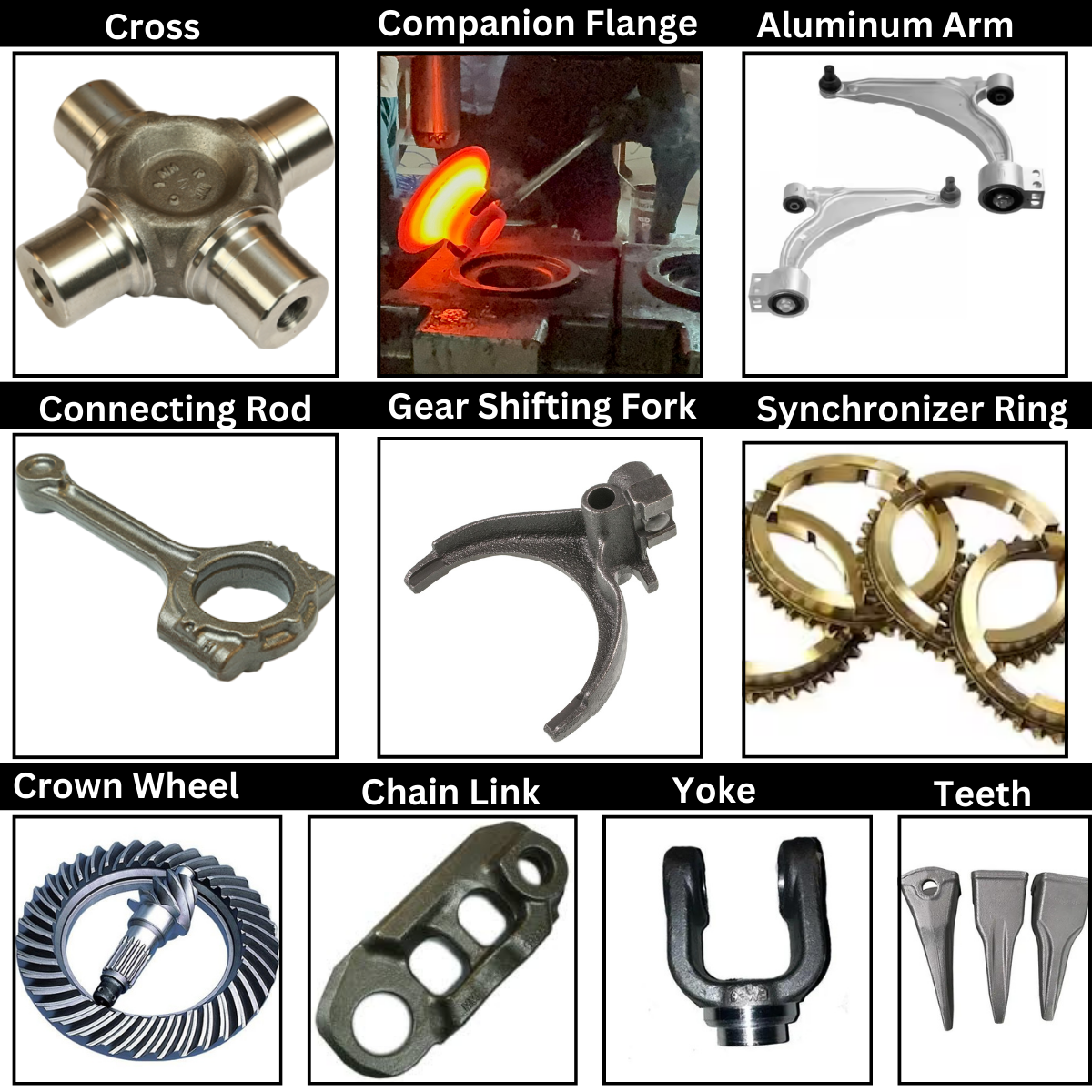

Electric Screw Press: The Key to Precision in Forging These Components

Electric Screw Press is capable of forging a wide range of high-quality components, including Claw Poles, Connecting Rods, Form Machinery, Spherical Hinges, Auto Parts, Control Arms, Rigging, and other steel forgings. In addition to steel, it also excels in forging non-ferrous metals such as Brass, Aluminum, and more, making it a versatile solution for diverse industrial applications. With its precision and reliability, this press ensures top-notch results across various metal types and forging processes.