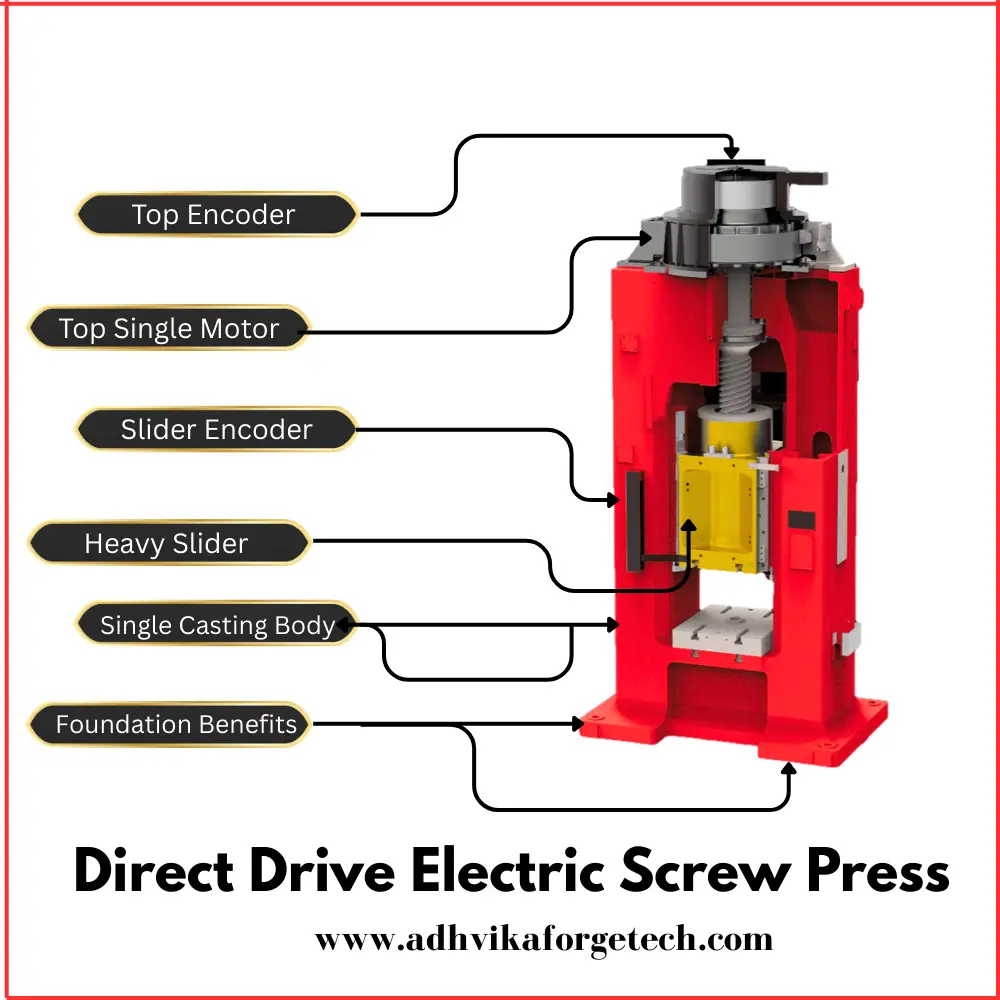

Direct Drive Electric Screw Press

What Is Direct Drive Electric Screw Press ?

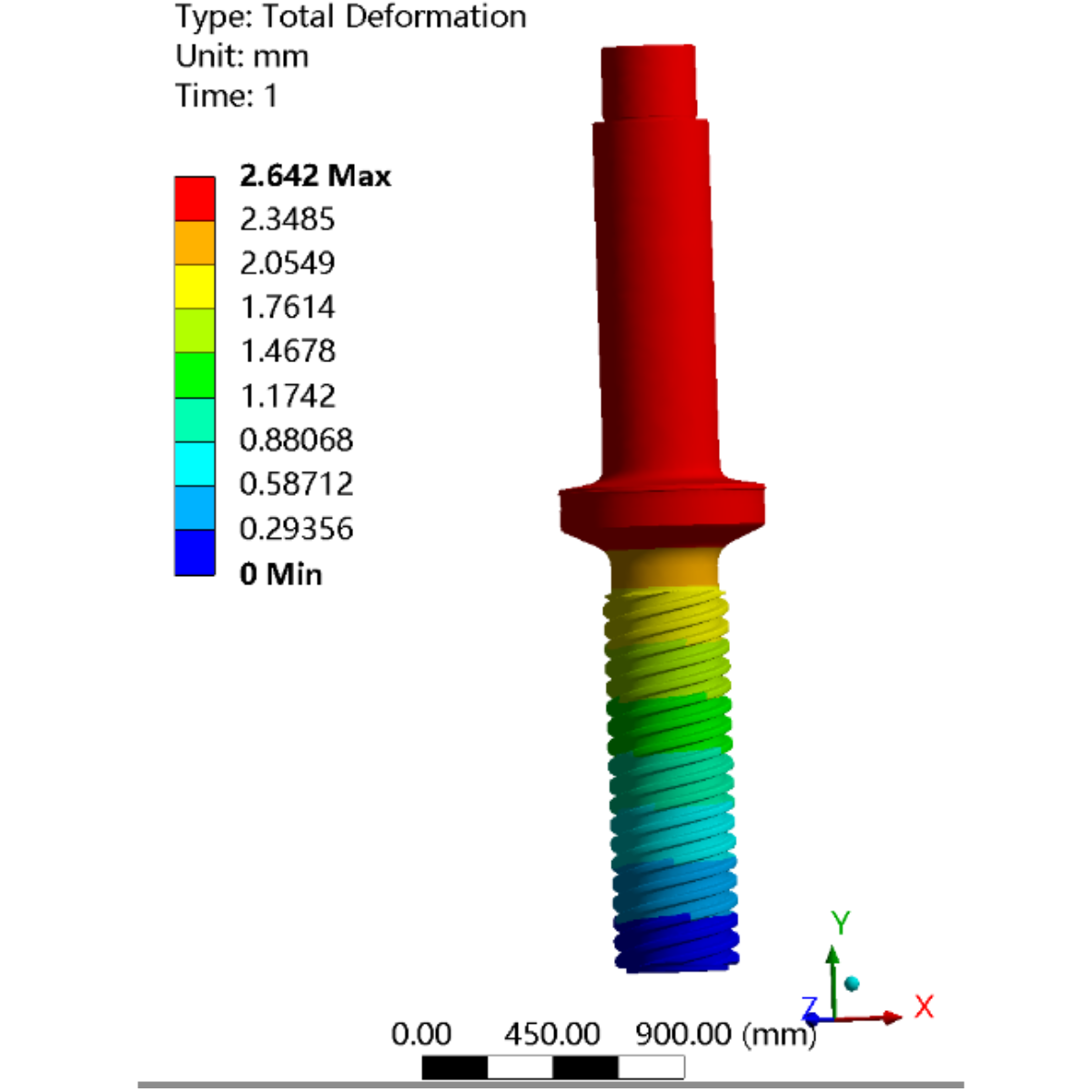

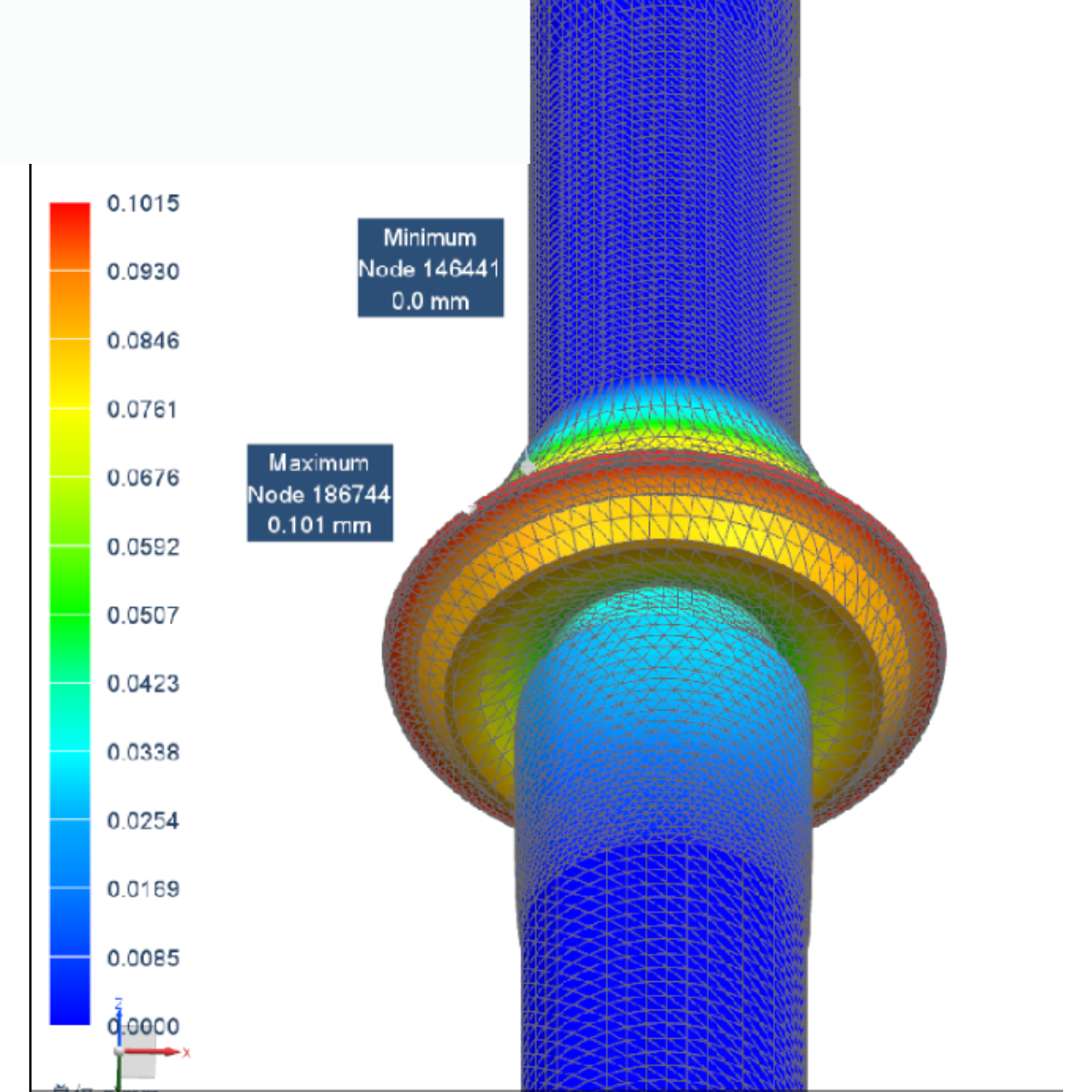

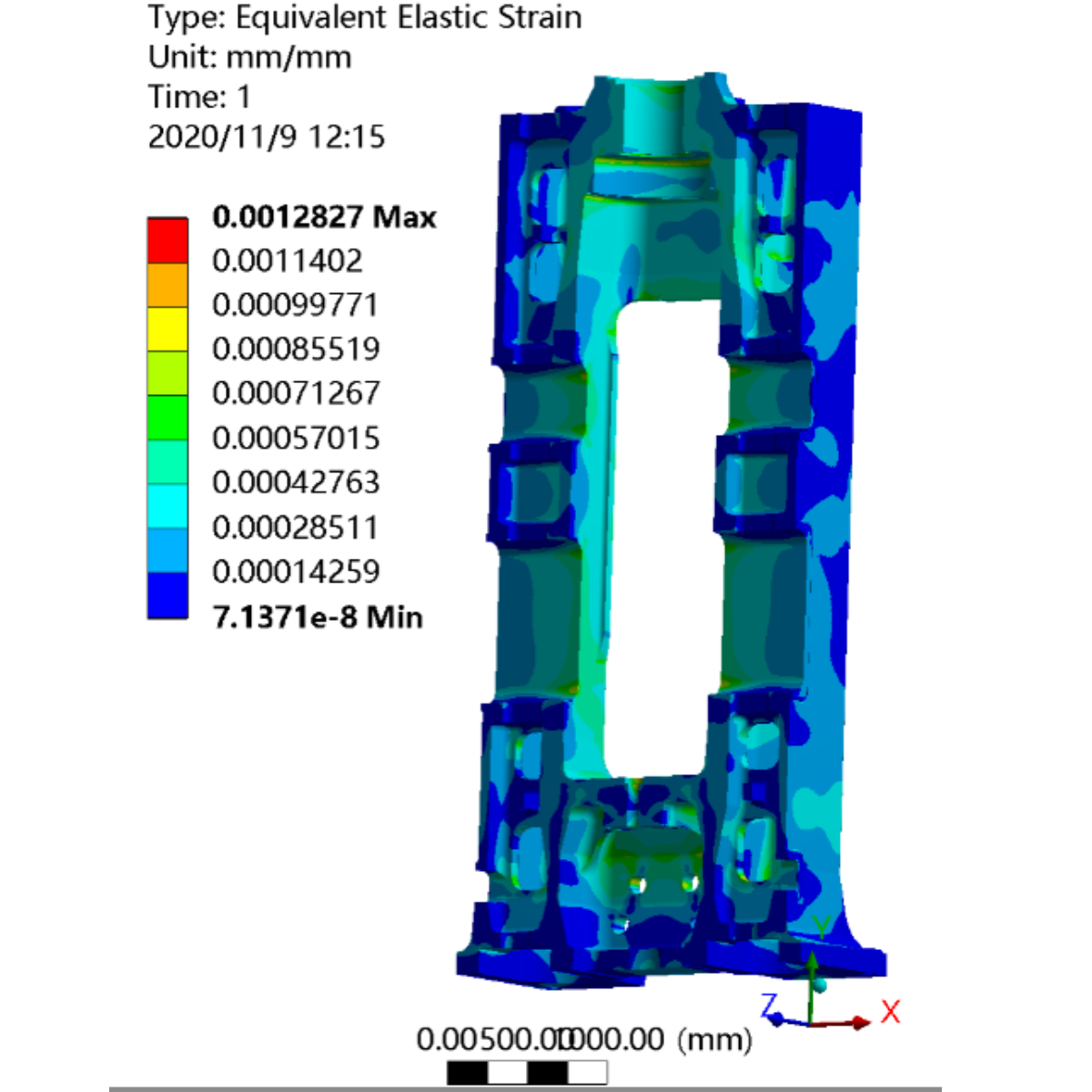

Direct Drive Electric Screw Press is one of the most advanced forging machines designed for precision, energy saving, and reliability. Unlike traditional friction screw presses or gear-driven models, the direct drive press eliminates intermediate mechanisms and directly connects the motor to the screw shaft. This results in higher accuracy, reduced energy loss, and lower maintenance costs, making it a preferred choice for modern forging plants.

Encoder

Motor

Sensor

Drive

🔹 Encoder

The press is equipped with an encoder that ensures the slider performs precise strokes, preventing excess load on the die and protecting both the tooling and the forging job.

🔹 Sensor

Advanced sensors guarantee that all interlocks function correctly, ensuring safe operation of the screw press, protecting operators, and maintaining smooth forging production.

🔹 Motor

A heavy-duty motor delivers maximum power to the forging press, providing strong impact energy for each stroke, enabling accurate shaping of metals in closed die forging lines.

🔹 ABB Drive

The ABB inverter drive ensures energy savings by adjusting motor performance according to load, optimizing forging efficiency, and reducing operating costs effectively.

Key Features

High Accuracy – Each stroke delivers exactly the required forging energy.

Energy Saving – No gear or friction loss, giving up to 30% power savings.

Low Maintenance – Simple design with fewer moving parts, reducing downtime.

Programmable Control – Equipped with servo drive and PLC, operators can set stroke energy, stroke length, and monitor digitally.

Quiet & Clean Operation – Much lower noise compared to traditional hammers or friction presses.

Advantages Over Traditional Presses

Traditional gear drive presses suffer from gear wear, lubrication issues, and power losses.

Friction presses rely on flywheel energy, which is less precise and consumes more energy.

A Direct Drive Electric Screw Press delivers high torque instantly, ensuring better grain flow, reduced flash, longer die life, and improved product quality.

Operating Parameters & Energy Details of Direct Drive Electric Screw Press

| Item | Unit | AD-160 | AD-250 | AD-315 | AD-400 | AD-630 | AD-1000 | AD-1600 | AD-2500 | AD-4000 |

| Nominal force | KN | 1600 | 2500 | 3150 | 4000 | 6300 | 10000 | 16000 | 25000 | 40000 |

| Max. working force | KN | 2500 | 4000 | 5000 | 6300 | 10000 | 16000 | 25000 | 40000 | 63000 |

| Max. forging energy | KJ | 10 | 15 | 20 | 40 | 80 | 160 | 280 | 500 | 1000 |

| Slide Stroke Length | mm | 300 | 320 | 380 | 400 | 450 | 500 | 600 | 630 | 750 |

| Theoretical Forging Strike | min⁻¹ | 30 | 28 | 26 | 20 | 19 | 18 | 15 | 14 | 10 |

| Min. enclose height | mm | 500 | 500 | 550 | 570 | 720 | 750 | 960 | 1050 | 1460 |

| Thickness of sow block | mm | 120 | 120 | 120 | 120 | 160 | 180 | 220 | 250 | 300 |

| Shut height Range of Die | mm | 380 ~ | 380 ~ | 430 ~ | 450 ~ | 560 ~ | 570 ~ | 740 ~ | 800 ~ | 1160 ~ |

| Size of worktable (width×depth) | mm | 600×560 | 600×560 | 700×640 | 750×730 | 820×900 | 920×1050 | 1000×1280 | 1200×1400 | 1600×1900 |

Forgings Made with Electric Screw Press

Electric Screw Presses are versatile machines widely used in closed die forging. They can forge automotive parts like connecting rods, control arms, riggings, spherical hinges, and claw poles. Beyond steel forgings, they are also suitable for non-ferrous metals such as brass, aluminum, and other alloys. This flexibility makes them ideal for industries including automotive, machinery, aerospace, and construction, ensuring high precision, material savings, and excellent product strength.