High-Performance Descaling Machines – Made in India by Adhvika Forge Tech

Adhvika Forge Tech is proud to offer high-performance descaling machines designed specifically for the forging industry in India. In modern forging operations, billets, bars, and other metal components are heated to extremely high temperatures before forming. During this heating process, a layer of oxide scale naturally forms on the metal surface. If this scale is not removed prior to forging, it can lead to poor surface quality, increased wear on forging dies, and higher scrap rates, which directly affects productivity and profitability.

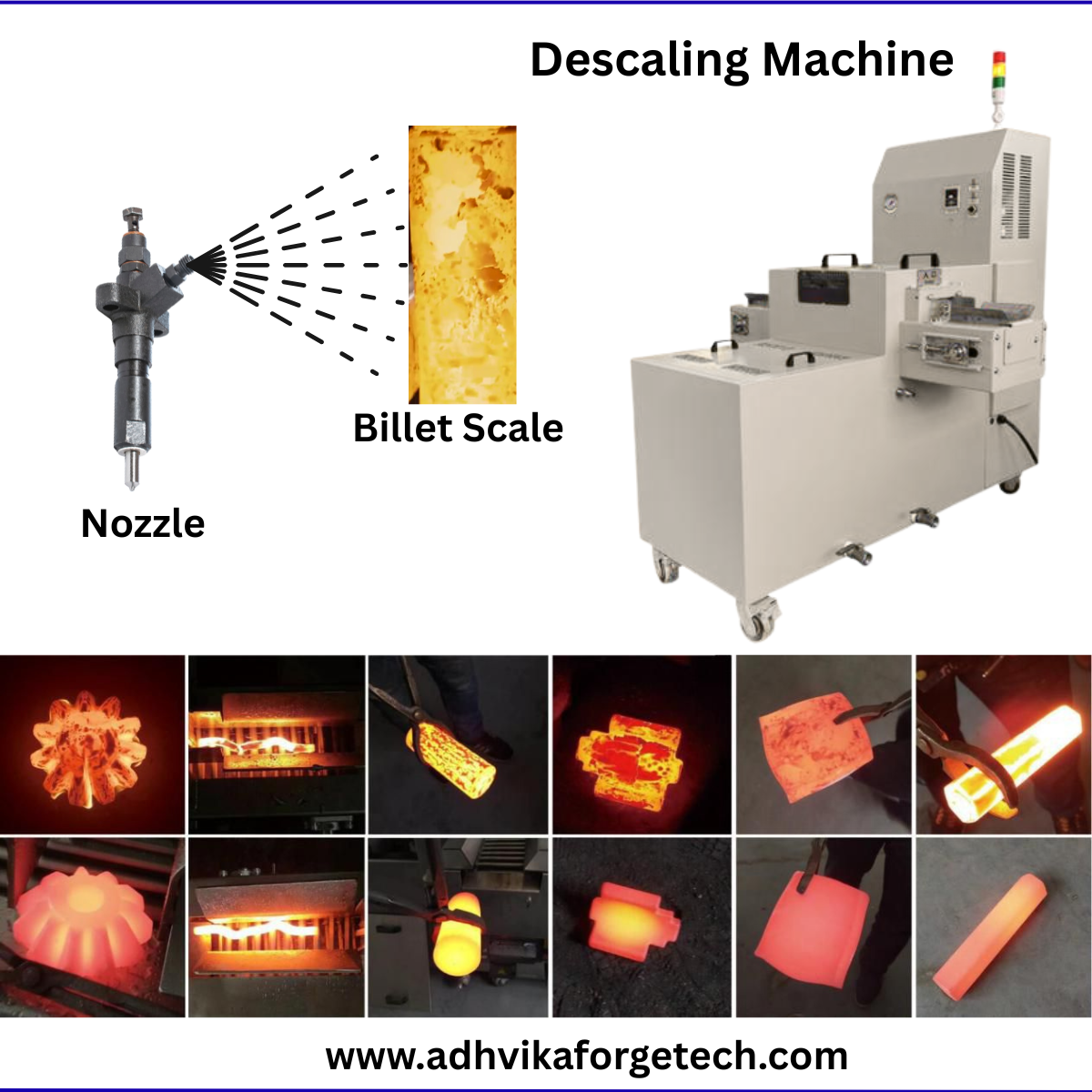

Our descaling machines are engineered to address these challenges efficiently and reliably. Using high-pressure water jets, the machines quickly remove oxide scale, dirt, and other surface impurities from hot billets, bars, shafts, flanges, and rings. This process not only ensures a smooth and clean surface finish but also significantly extends the life of forging dies and tooling, reducing maintenance costs and operational downtime.

Why Descaling is Crucial in Forging:

In the forging industry, the quality of the final product largely depends on the condition of the input material. Oxide scale can cause surface defects, cracks, and uneven material flow during forging, leading to rejected components. Descaling before forging ensures that the metal is clean, uniform, and ready for precise forming, whether for automotive shafts, aerospace components, defense products, or heavy engineering parts.

How Adhvika Forge Tech Descaling Machines Work:

Our machines use high-pressure water jets directed at red-hot metal surfaces. The jets are carefully calibrated in terms of pressure, angle, and flow to ensure complete removal of surface scale without damaging the metal. Adjustable nozzles and variable water pressure allow the system to handle a wide range of component sizes, from small shafts and rods to large billets and forged flanges. The machines can operate fully automatically as part of a forging line or in semi-automatic mode depending on the plant requirements.

Key Features & Benefits:

Smooth Surface Finish: Removes oxide scale effectively, ensuring superior surface quality.

Die Protection: Reduces friction and wear on forging dies, extending their operational life.

Reduced Scrap: Minimizes defects and wastage during forging, improving yield.

High Productivity: Quick descaling cycles integrate seamlessly into continuous forging lines.

Versatile Application: Suitable for steel, alloy steel, aluminum, titanium, and nickel-based alloys.

Energy Efficient: Modern pumps and optimized water consumption ensure lower operational costs.

Customizable Design: Machines can be tailored for different billet sizes, line configurations, and production capacities.

Typical Specifications:

Material Handled: Steel, Alloy Steel, Aluminum, Titanium, Nickel Alloys

Billet Size Range: 20mm – 400mm (customizable)

Water Pressure: 50 – 150 bar (adjustable)

Machine Length: 2m – 8m (depending on line configuration)

Capacity: 1 – 10 tons/hour

Control System: PLC-controlled with safety interlocks and automatic operation