We manufacture top-class power presses for forging, upsetting, and piercing operations. Our presses are designed for precision, durability, and high efficiency, delivering superior performance in the forging industry.

Power Press - High-Performance Forging Solutions

Introduction:

Adhvika Forge Tech, we specialize in manufacturing top-class power presses designed for a range of forging operations, including upsetting, piercing, and other advanced forging techniques. Our power presses are engineered for precision, durability, and efficiency, ensuring that each operation is completed with the highest standards of performance. These machines are ideal for various forging industries, delivering unmatched results for heavy-duty operations.

Working Principle:

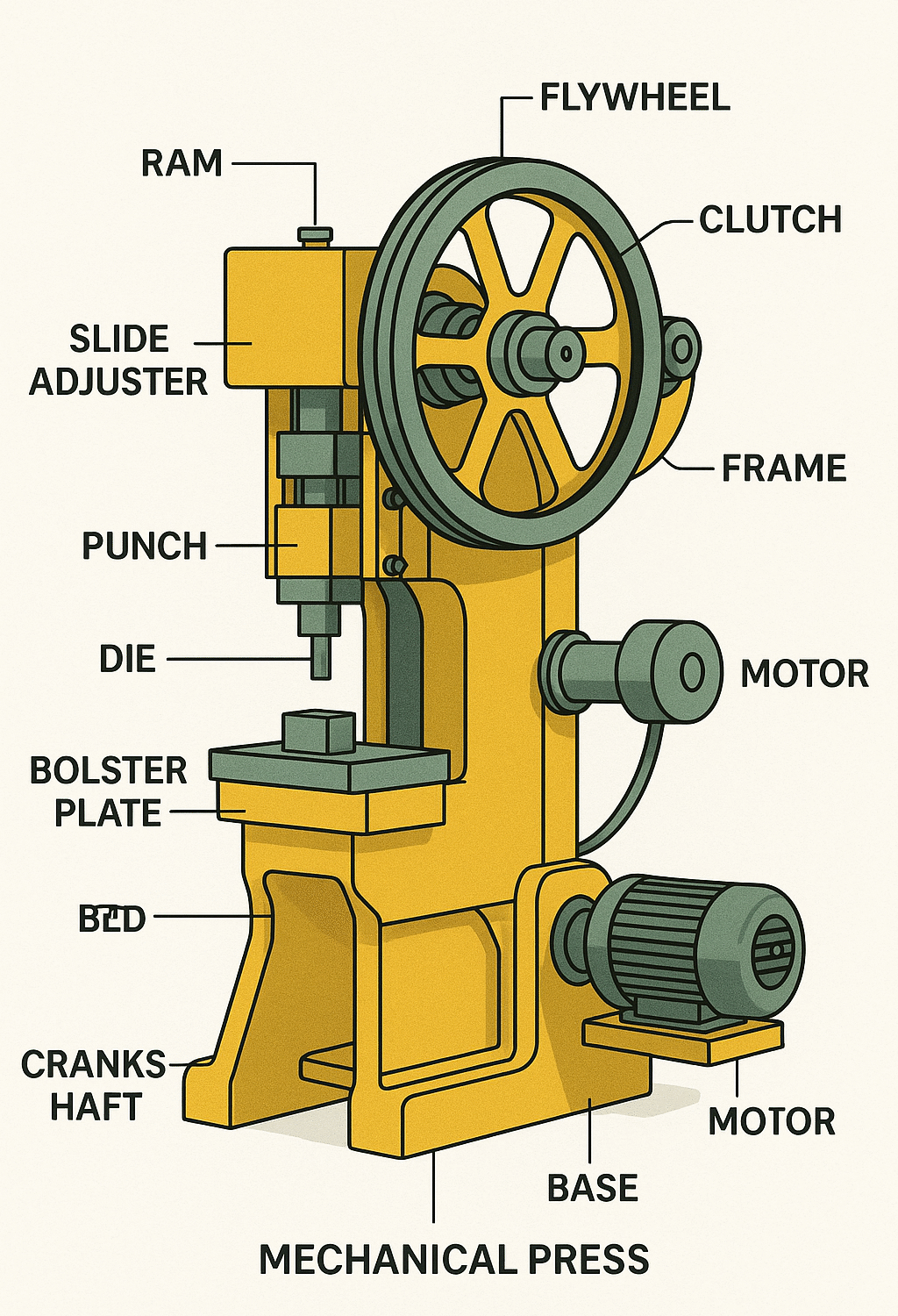

Our power presses operate using a mechanical, hydraulic, or pneumatic system to deliver high force to materials, shaping them into the desired form. The press works by utilizing a combination of applied force, mechanical advantage, and consistent operation to produce the intended forging results. Whether it’s upsetting, piercing, or blanking, our presses ensure consistent pressure application, achieving optimal results with minimal downtime.

Machine Specifications:

Press Type: Mechanical, Hydraulic, or Pneumatic

Capacity Range: From 25 tons to 800 tons (customizable)

Stroke Length: Variable, adjustable to meet specific needs

Ram Speed: High-speed ram for fast cycle times

Bed Size: Customizable to suit workpiece dimensions

Daylight Opening: Adjustable for various workpiece sizes

Control Systems: PLC-based for precision control

Safety Features: Equipped with overload protection, emergency stop, and safety guards for operator safety.