Direct Drive Electric Screw Press – Assembly & Working Principle

🔍 What is an Electric Screw Press?

An Electric Screw Press is a forging machine driven by an electric motor that applies force through a rotating screw. It eliminates the need for mechanical flywheels or friction drives, ensuring high accuracy and control, ideal for hot, warm, and precision forging.

🌀 Types of Electric Screw Presses

Direct Drive Screw Press

Powered directly by a servo-controlled motor.

No flywheel or clutch.

Offers real-time feedback, energy efficiency, and quick reversing.

Servo Drive Screw Press

Utilizes a servo motor to control the rotation and stopping of the screw.

Equipped with encoder feedback and PLC control (typically Siemens or Mitsubishi).

Ensures repeatable forging, programmable stroke, and force monitoring.

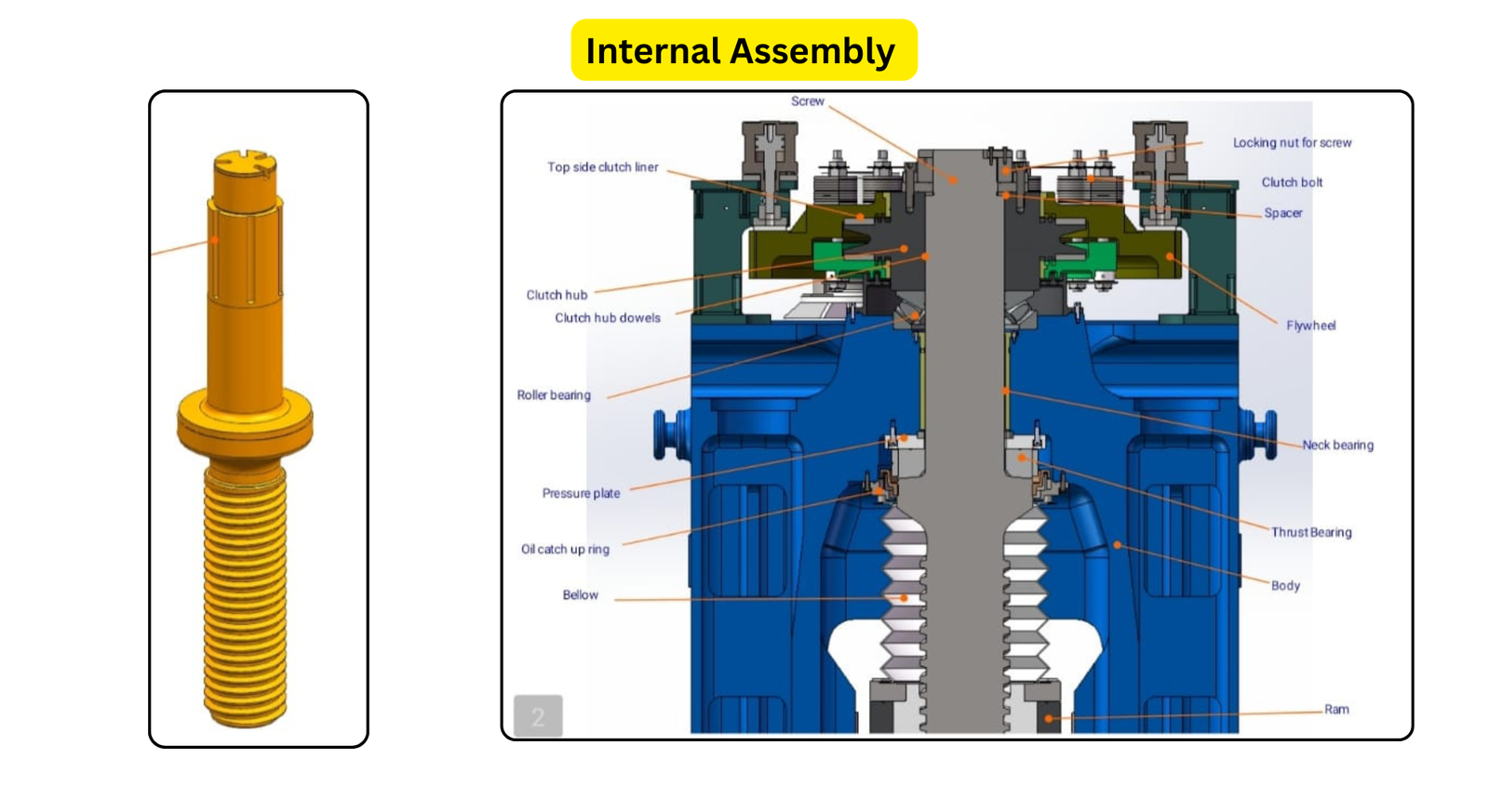

🧱 Internal Assembly – Electric Screw Press

🔩 Top Section – Drive & Clutch Assembly

Screw: Main transmission shaft converting rotary motion to linear force.

Locking Nut for Screw: Secures the screw from backward play or loosening.

Top Side Clutch Liner: Friction surface that engages with the flywheel when pressure is applied.

Clutch Bolt & Spacer: Maintain the gap and provide secure clutch connection.

Clutch Hub & Clutch Hub Dowels: Transfers motor torque precisely; dowels ensure alignment.

Flywheel: Rotational energy storage (in traditional types; not used in true direct drive).

Roller Bearing: Reduces rotational friction, supports smooth operation.

🏗️ Mid Section – Load Transfer & Support

Pressure Plate: Applies force to engage clutch liner with flywheel.

Oil Catch Up Ring: Prevents leakage of lubricating oil, maintaining system cleanliness.

Bellows: Protect the spindle and inner parts from dust, debris, and oil splashes.

Neck Bearing: Radial bearing supporting axial motion of the screw shaft.

🛠️ Lower Section – Forging Force & Base Structure

Thrust Bearing: Takes the axial load during pressing, preventing shaft wear.

Body: Main machine housing structure, supports ram and guides alignment.

Ram: Moves downward under screw force to press the heated material.

Forging Die (not shown): Mounted on ram to form the metal workpiece.

⚡️ Advantages of Direct Drive / Servo Electric Screw Press

| Feature | Benefit |

|---|---|

| 🔄 Reversible Motion | Quick up/down stroke for flashless forging |

| 🎯 Programmable Control | Force, stroke, and position accuracy |

| 🔋 Energy Efficiency | No flywheel, minimal idle loss |

| 🛠️ Low Maintenance | Fewer mechanical parts, less wear |

| 🧠 Intelligent Feedback | Closed-loop system using encoders and sensors |

Key Applications of Electric Screw Press in Modern Forging