Adhvika Forge Tech : Aerospace Forging Solutions & Development

Aerospace Industry

Forging plays a crucial role in the aerospace industry, where strength, reliability, and precision are essential. Forged components are used in aircraft, helicopters, spacecraft, and defense applications due to their high durability, lightweight properties, and resistance to extreme conditions.

Scope of Forging in Aerospace

✅ High Strength & Durability – Forged parts withstand extreme pressure, temperature, and stress.

✅ Weight Reduction – Lightweight forged aluminum and titanium improve fuel efficiency.

✅ Precision & Safety – Critical aircraft components require accurate and defect-free forging.

✅ Advanced Materials – Titanium, aluminum alloys, and high-strength steels are commonly used.

✅ Long Service Life – Forged parts enhance the longevity and reliability of aerospace systems.

Forged Parts in Aerospace Industry

🚀 Engine Components – Turbine disks, fan blades, compressor rings, shafts.

🛩 Structural Components – Wing fittings, landing gear components, brackets.

⚙️ Transmission & Gear Components – Bevel gears, shafts, couplings.

💺 Fasteners & Connecting Parts – Bolts, nuts, and critical joints for aircraft assembly.

🚁 Helicopter Parts – Rotor hubs, drive shafts, and control linkages.

At #AdhvikaForgeTech, we specialize in high-precision aerospace forging solutions, offering cost-effective and high-performance forged components for aviation, space, and defense applications. 🌍✈️

Inconel 718 & 625 Forging Solutions

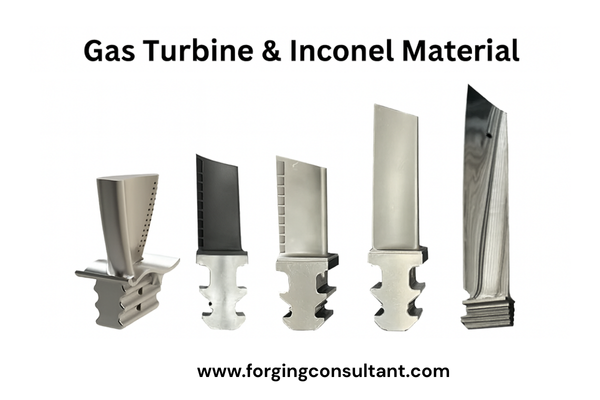

Inconel Superalloy Forging Solutions for Gas Turbines

In the aerospace and power generation industry, Inconel superalloys are widely used to manufacture critical gas turbine components due to their exceptional high-temperature strength, corrosion, and oxidation resistance. Key forged items include turbine blades (airfoils), guide vanes, and rotor discs, which are specifically designed to withstand extreme heat and stress in the hot sections of gas turbines.

Beyond these, other essential forged components include compressor discs, cases, shafts, couplings, rings, and combustor hardware, all of which play a vital role in ensuring jet engine efficiency, reliability, and long service life.

Commonly used Inconel grades such as Inconel 718 and 625 are preferred for blades, discs, nozzles, and exhaust components because of their outstanding creep-fatigue performance, making them ideal for high-stress, high-temperature environments in modern aerospace applications.

At Adhvika Forge Tech, we provide complete forging solutions for Inconel components—from material selection and die design to precision forging, heat treatment, and final inspection, ensuring high-quality, reliable components for the demanding needs of aerospace and gas turbine industries.